BOSM -Horizontal Counter Drilling kunye Machine Boring

1. Ukusetyenziswa kwezixhobo:

I-BOSM ethe tyaba yokubhola kunye nomatshini odikayo ngumatshini okhethekileyo wenkampani yakho ukuba iqhubekisele phambili iminqwazi ye-crane. Umtshini uxhotyiswe ngeeseti ezi-2 zokomba othe tyaba kunye neentloko zamandla adinayo, ezinokuqonda ukugrumba, ukucola kunye nokudinwa kwezinto zokusebenza ngaphakathi koluhlu olusebenzayo lwe-stroke. Ukusika kunye nokunye ukusetyenzwa, isantya sokumisa izixhobo sikhawuleza, ukuchaneka kokulungiswa kuphezulu, kunye nokusebenza kakuhle kuphezulu.

2. Iimpawu zesakhiwo sezixhobo:

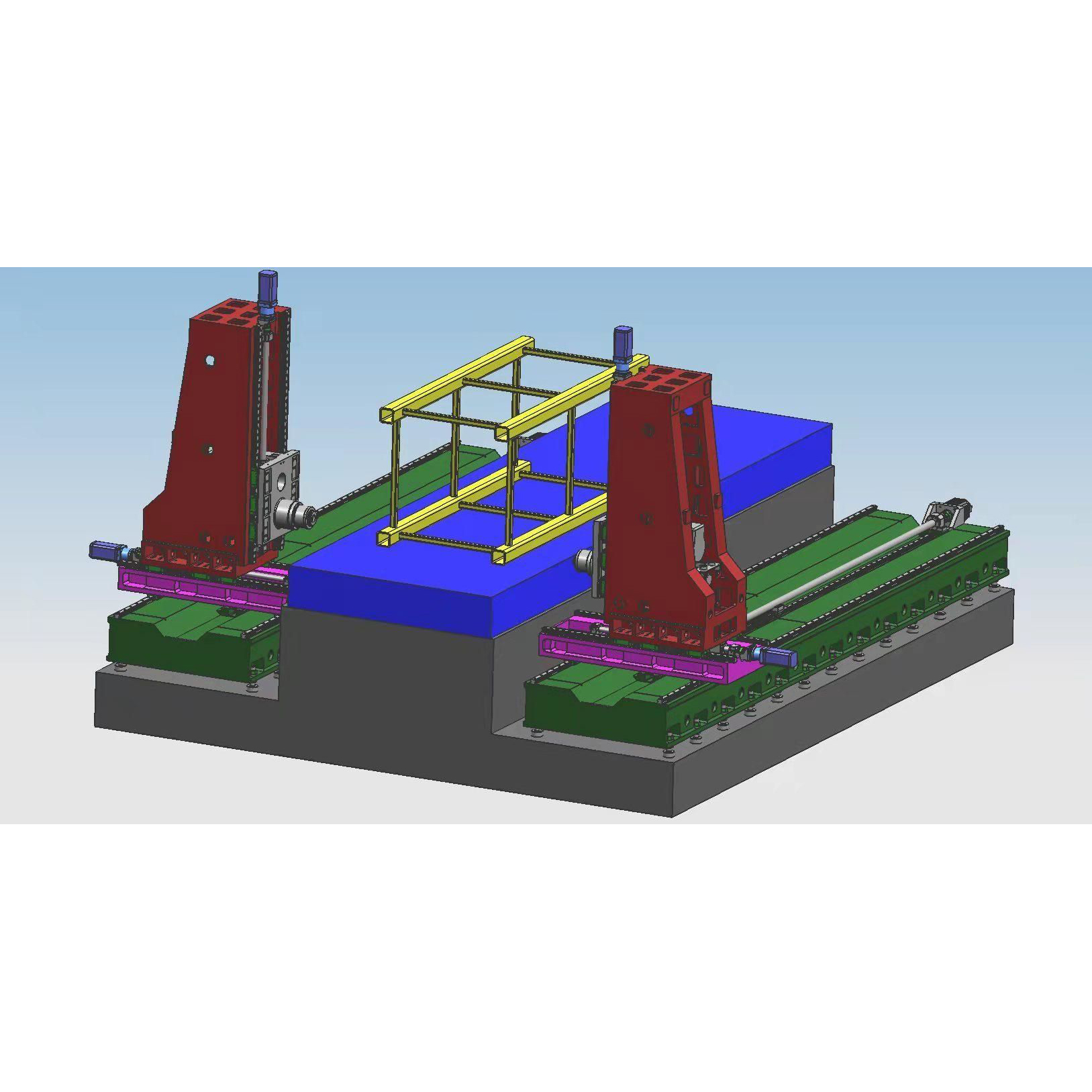

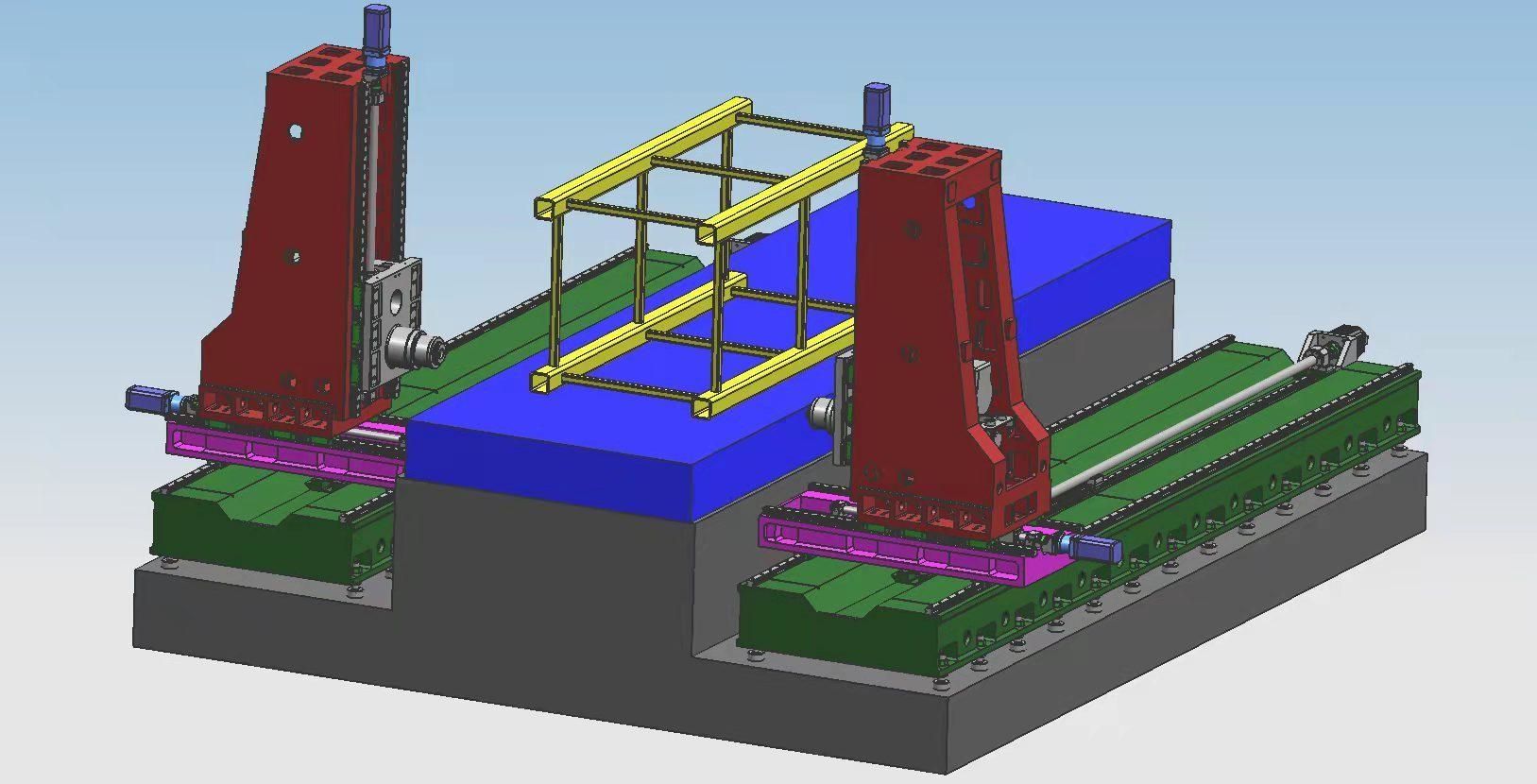

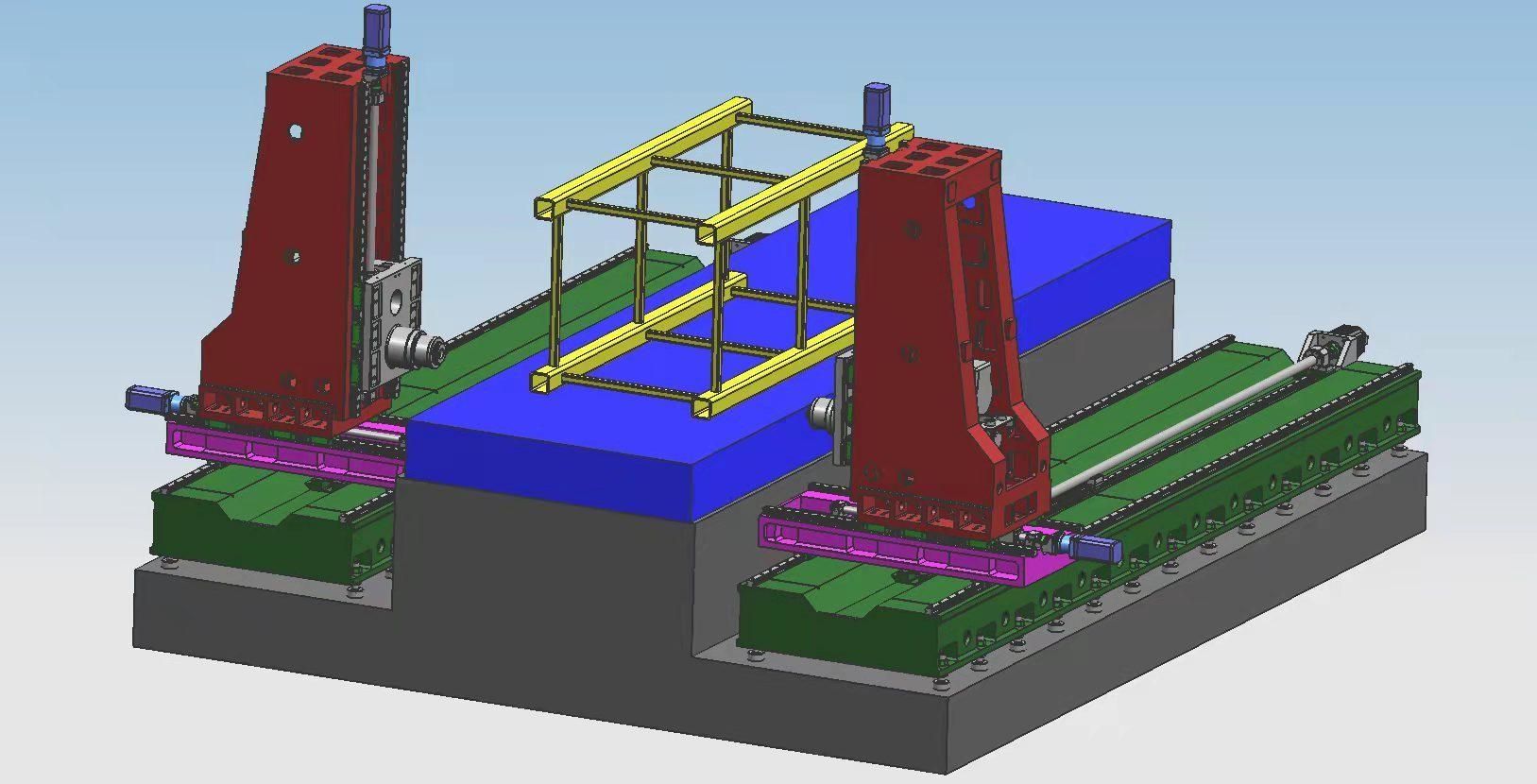

2. 1. Amacandelo aphambili eUmatshini

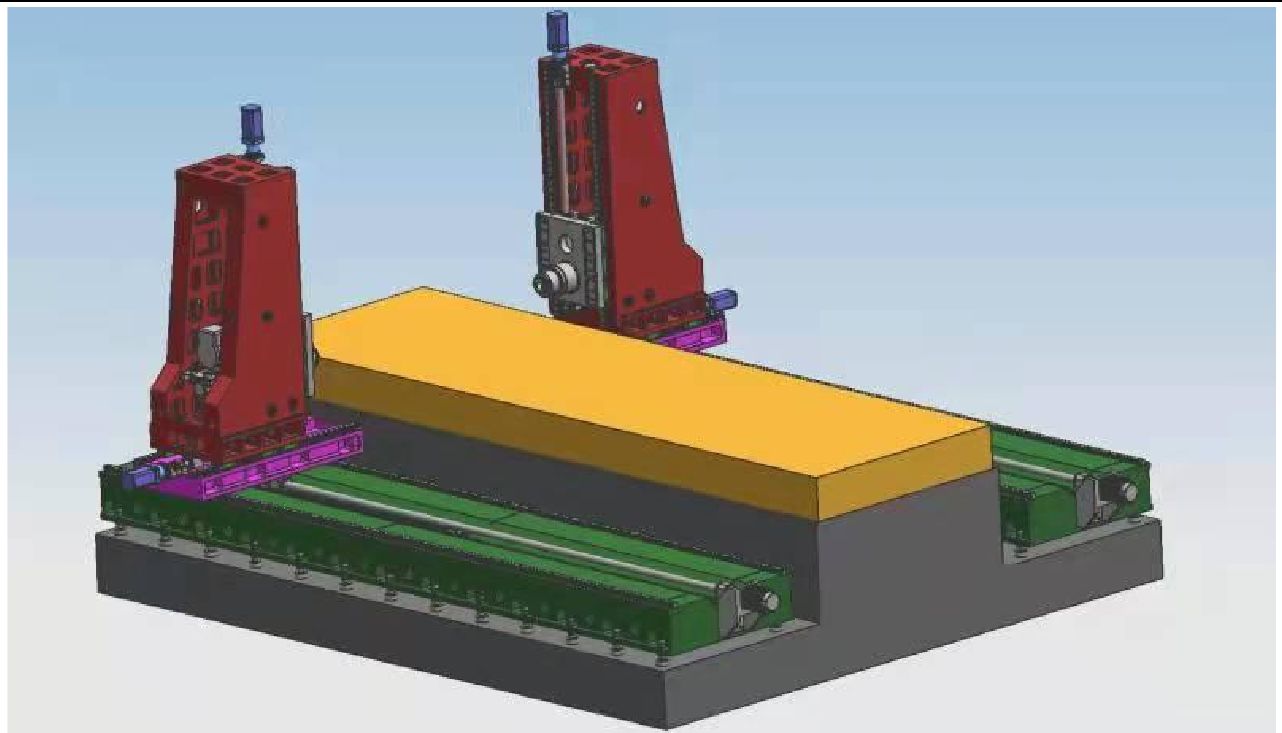

Izinto eziphambili zoMatshini: ibhedi, itafile yokusetyenzwa, iikholamu zasekhohlo nasekunene, iisali, iinkunzi zeegusha, njl. njl., iindawo ezinkulu zenziwe ngokubunjwa kwentlabathi yeresin, umgangatho ophezulu wentsimbi engwevu 250, ifakwe kumngxuma wesanti oshushu → ukungcangcazela → kushushu ukucima eziko→ukungcangcazela ukuguga→Umatshini orhabaxa→ukungcangcazelisa ukuguga→ukucima eziko→ukungcangcazela ukuguga→ukugqiba ukuphelisa ngokupheleleyo uxinzelelo olubi lwamalungu kunye nokugcina ukusebenza kwamalungu kuzinzile. I-workbench yezixhobo igxininiswe, kwaye iintloko zamandla kumacala omabini ziyakwazi ukuhamba ngaphambili nangasemva kwesiseko; Umatshini unemisebenzi efana nokubhola, ukukruqula, ukucwila, ukucofa, njl njl. Indlela yokupholisa yesixhobo kukupholisa kwangaphakathi kunye nokupholisa kwangaphandle. Umtshini uqukethe ii-axes ze-5 zokutya, iintloko zamandla ezi-2 zokusika, ezinokudityaniswa kunye ne-5 axes ngexesha elifanayo, okanye ingaba yinto enye. Isalathiso se-axial yoMshini kunye nentloko yamandla iboniswe kumzobo ongezantsi.

2. 2 Isakhiwo esiphambili se-axial transmission feed part

2.2.1 X axis: Intloko yamandla ibuyela ecaleni ecaleni komzila wesikhokelo wesiseko.

I-X1-axis drive: I-AC servo motor kunye ne-high-precision i-planetary reducer isetyenziselwa ukuqhuba intloko yamandla kwi-ball screw drive ukuqaphela intshukumo yomgca we-X-axis.

Ukuhanjiswa kwe-X2-axis: I-AC servo motor kunye ne-high-chane-chane isinciphisi seplanethi isetyenziselwa ukuqhuba intloko yamandla ngokusebenzisa i-ball screw transmission ukuqonda i-X-axis linear motion.

Ifom yesikhokelo sikaloliwe: Iindlela ezimbini zesikhokelo ezichanekileyo ezichanekileyo ezichanekileyo zifakwe kwiithayile kwisiseko esandisiweyo.

2.2 Umgca we-Y1: Intloko yamandla ibuyela phezulu nasezantsi kwikholamu.

I-Y1-axis drive: Yamkela i-AC servo motor ukuze uqhube nge-screw yebhola ukuqonda intshukumo yomgama we-Y1-axis. Ifom yesikhokelo sikaloliwe: Iziqwenga ezi-4 ze-45 uhlobo lweereyile zesikhokelo ezihambelanayo.

2.2.3 Umgca we-Y2: Intloko yamandla ibuyela phezulu nasezantsi kwikholamu.

I-Y2-axis transmission: I-AC servo motor isetyenziselwa ukuqhuba nge-screw yebhola ukuqonda intshukumo yomgca we-Y1-axis.

Ifom yesikhokelo sikaloliwe: Iziqwenga ezi-4 ze-45 uhlobo lwee-rails zesikhokelo somgca.

2.2.4 Umgca we-Z1: Intloko yamandla ibuyela emva naphambili kwisali.

Ukuhanjiswa kwe-Z1-axis: I-AC servo motor kunye ne-high-precision i-planetary reducer isetyenziselwa ukuqhuba ukunyakaza nge-screw yebhola ukuze iqonde ukunyakaza komgca we-Z1-axis.

2.2.5 Umgca we-Z2: Intloko yamandla ibuyela emva naphambili kwisali.

Ukuhanjiswa kwe-Z2-axis: I-AC servo motor kunye ne-high-precision i-planeter reducer isetyenziselwa ukuqhuba intshukumo nge-screw yebhola ukuze iqonde i-Z2-axis intshukumo yomgca.

2.3. Ukususwa kwe-chip kunye nokupholisa

Kukho izihambisi zetshiphu ezisicaba ezifakwe kumacala omabini phantsi kwebhentshi yokusebenza, kwaye iitshiphusi zentsimbi zinokukhutshelwa kwisihambisi setshiphu ekugqibeleni ukuze kuphunyezwe imveliso ephucukileyo. Kukho impompo yokupholisa kwitanki yokupholisa yokuhambisa itshiphu, engasetyenziselwa ukupholisa kwangaphakathi + ukupholisa kwangaphandle kwesixhobo ukuqinisekisa ukusebenza kunye nobomi benkonzo yesixhobo, kunye nesipholisi sinokuphinda sisetyenziswe.

3. Inkqubo yolawulo lwamanani edijithali epheleleyo:

3.1. Ngomsebenzi wokuqhekeka kwetshiphu, ixesha lokuqhekeka kwetshiphu kunye nomjikelo wokuqhekeka kwetshiphu unokusetwa kujongano lomatshini womntu.

3.2. Ngomsebenzi wokuphakamisa isixhobo, umgama wokuphakamisa isixhobo unokusetwa kujongano lomatshini womntu. Xa umgama ufinyelelwe, isixhobo siya kuphakanyiswa ngokukhawuleza, kwaye iichips ziya kuphoswa kude, kwaye emva koko zikhawuleze ukuya kwindawo yokugaya kwaye ziguqulelwe ngokuzenzekelayo ukuba zisebenze.

3.2. Ibhokisi yolawulo lokusebenza esembindini kunye neyunithi ephathwayo yamkele inkqubo yolawulo lwamanani kwaye ixhotyiswe ngojongano lwe-USB kunye nomboniso we-LCD wekristale engamanzi. Ukuze kuququzelelwe inkqubo, ukugcinwa, umboniso kunye nonxibelelwano, ujongano lokusebenza lunemisebenzi efana nencoko yababini yomatshini, imbuyekezo yempazamo, kunye ne-alamu ezenzekelayo.

3.2 .. Isixhobo sinomsebenzi wokujonga kuqala kunye nokuhlola kwakhona indawo yokubeka umngxuma ngaphambi kokucutshungulwa, kwaye ukusebenza kukulungele kakhulu.

4. Ukuthambisa okuzenzekelayo

Ukuchaneka komatshini izibini zesikhokelo zikaloliwe ezichanekileyo, izibini ezichanekileyo zebhola kunye nezinye iiperi ezichanekileyo eziphezulu zixhotyiswe ngeenkqubo zokuthambisa ezizenzekelayo. Ipompo yokuthambisa ngokuzenzekelayo ikhupha i-oyile yoxinzelelo, kwaye igumbi le-oyile ye-lubricator yobungakanani ingena kwioyile. Xa igumbi leoli lizaliswe ngeoli kunye noxinzelelo lwenkqubo lukhuphukela kwi-1.4 ~ 1.75Mpa, ukutshintshwa koxinzelelo kwinkqubo ivaliwe, ipompo iyayeka, kwaye i-valve yokukhulula ikhutshwe ngexesha elifanayo. Xa uxinzelelo lwe-oyile kwindlela yehla ngaphantsi kwe-0.2Mpa, i-lubricator yobungakanani iqala ukuzalisa indawo yokuthambisa kwaye igqibe ukuzaliswa kweoli enye. Ngenxa yesixa esichanekileyo seoyile ebonelelwa yi-oiler yobungakanani kunye nokukwazi ukubona uxinzelelo lwenkqubo, unikezelo lweoyile luthembekile kwaye luqinisekisa ukuba kukho ifilimu yeoli kumphezulu wesibini ngasinye sekinematic, enciphisa ukungqubana kunye nokunxiba kunye nokuthintela umonakalo. kwisakhiwo sangaphakathi esibangelwa kukufudumala. , ukuqinisekisa ukuchaneka kunye nobomi boMshini.

5. Umatshinisebenzisa imeko-bume:

Ubonelelo lwamandla: Isigaba esithathu AC380V±10%, 50Hz±1 Ubushushu be-Ambient: -10°~ 45°

6. Indlela yokwamkela:

I-JB/T10051-1999 "Iinkcukacha zobuGcisa ngokuBanzi kwiNkqubo ye-Hydraulic ye-Metal Cutting Machines"

7. Iiparamitha zobugcisa:

| Umzekelo | 2050-5Z | |

| Ubungakanani bobungakanani bomsebenzi wokusetyenzwa | Ubude × ububanzi × ubude (mm) | 5000×2000×1500 |

| ubungakanani bedesika esebenzayo | Ubude X Ububanzi (mm) | 5000*2000 |

| Uhambo lwesiseko solawulo lwentloko yamandla | Yiya emva naphambili (mm) | 5000 |

| Amandla entloko phezulu naphantsi | Ukubetha phezulu naphantsi kwenkunzi yegusha (mm) | 1500 |

|

Uhlobo lwenkunzi yegusha ethe tyaba yokomba intloko yamandla Intloko yamandla 1 2 | Ubungakanani (2 iipcs) | 2 |

| I-Spindle taper | BT50 | |

| Idayamitha yokomba (mm) | Φ2-Φ60 | |

| Ukucofa idayamitha (mm) | M3-M30 | |

| Isantya sokujikeleza (r/min) | 30-3000 | |

| Amandla e-Servo spindle motor (kw) | 22*2 | |

| Uhambo lwasekhohlo nasekunene (mm) | 600 | |

| Ukuchaneka kokuma kweBidirectional | 300mm*300mm | ±0.025 |

| Ukuchaneka kokumisa okuphindwe kabini | 300mm*300mm | ±0.02 |