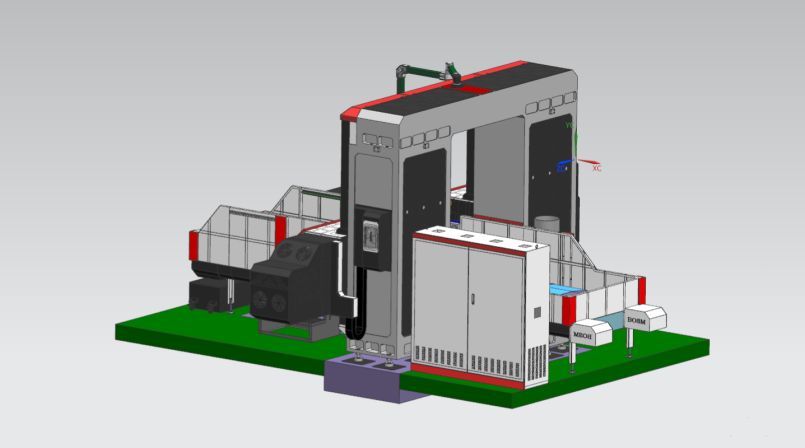

I-BOSM -5020-5Z Ichasa-iNtloko yokuBonga uMshini wokuBonga

1. Ukusetyenziswa kwezixhobo:

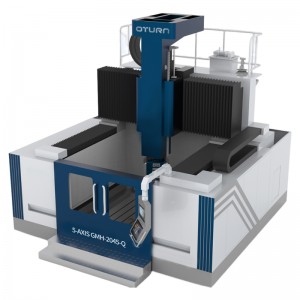

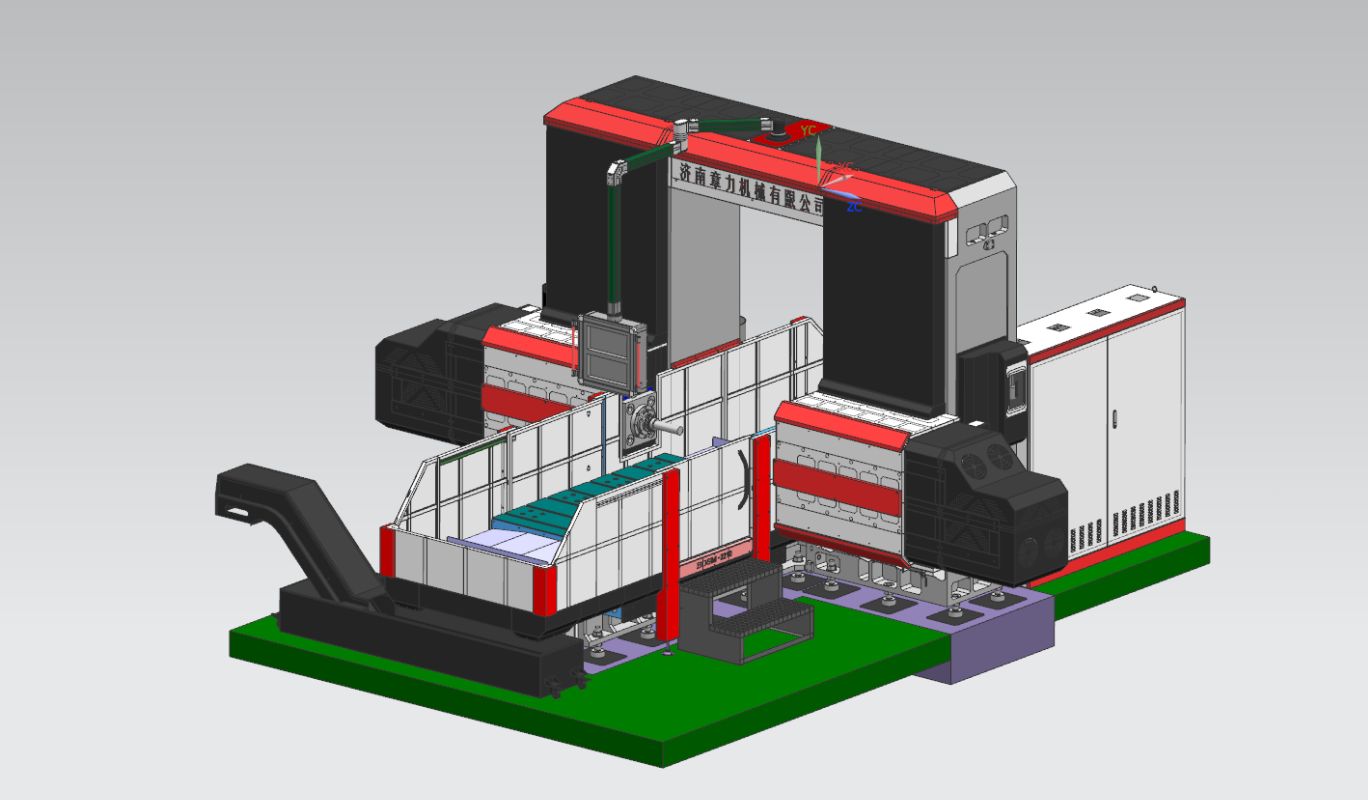

I-BOSM-5020-5Z CNC workbench mobile double-column head-to-head boring and milling machine is a special Machine for engineering machines symmetrical workpieces. Umtshini uxhotyiswe ngebhentshi ekhethekileyo eshukumayo kunye neeseti ezimbini zeenkunzi zeegusha ezithe tye, ezinokuqonda ukuGwatywa, ukugaya, ukudinwa kunye nokunye ukusetyenzwa kwendawo yokusebenza ngaphakathi koluhlu olusebenzayo lwe-stroke, i-workpiece inokucutshungulwa endaweni ngexesha elinye (akukho mfuneko i-clamping yesibini), ukulayisha ngokukhawuleza kunye nesantya sokukhulula, isantya sokumisa ngokukhawuleza, ukuchaneka okuphezulu kunye nokusebenza okuphezulu.

2. Ubume bezixhobo:

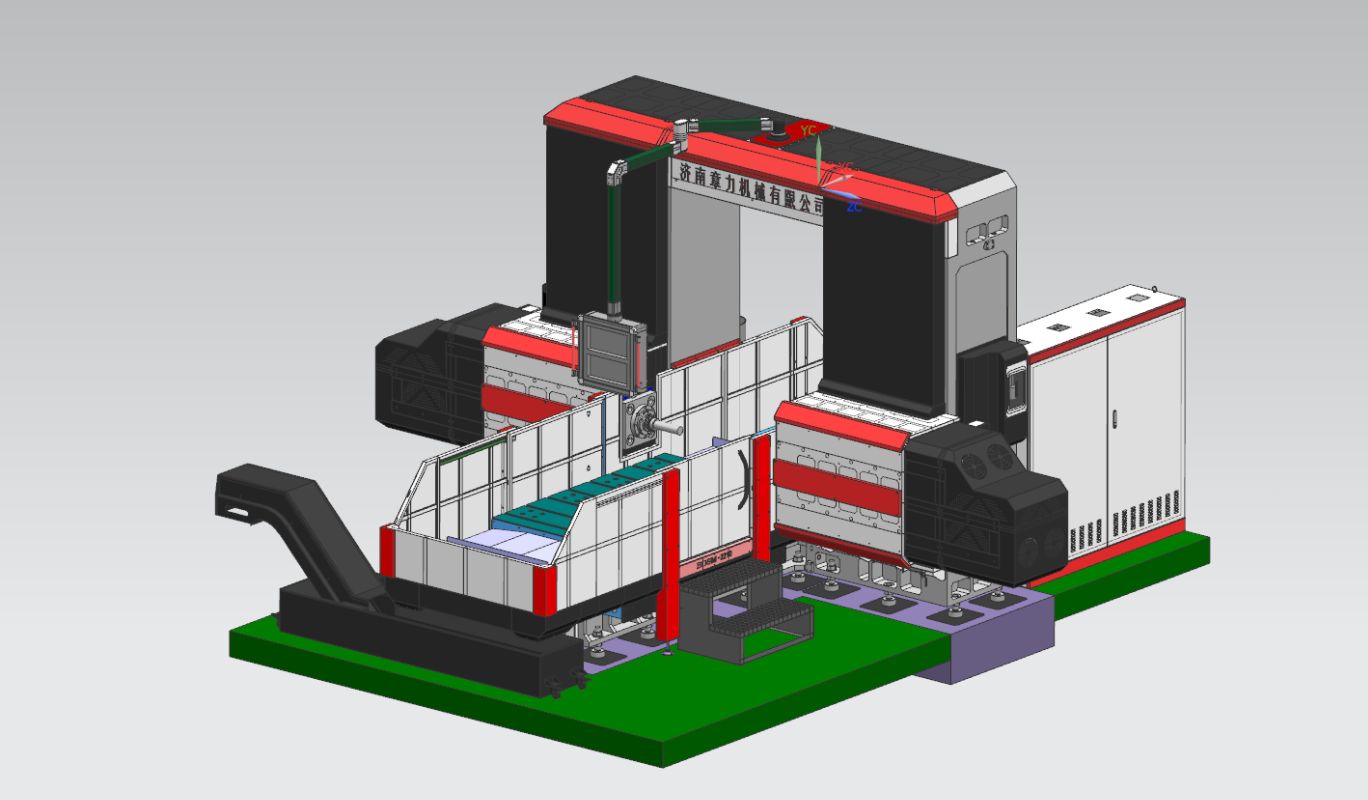

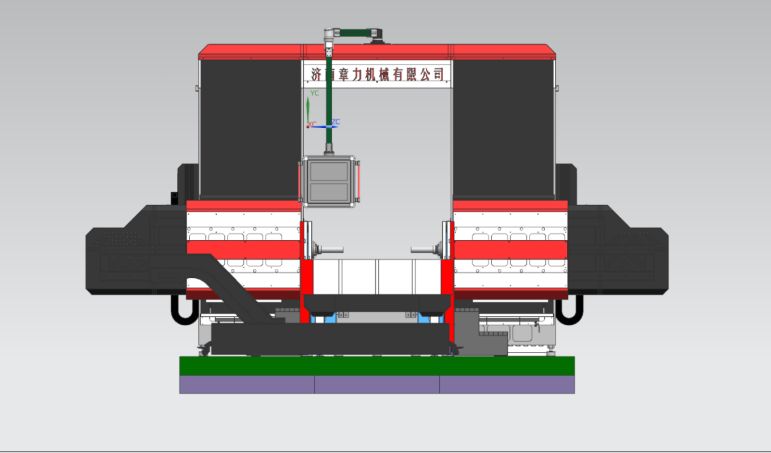

2.1. Amacandelo aphambili oMashini

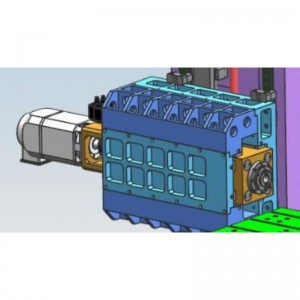

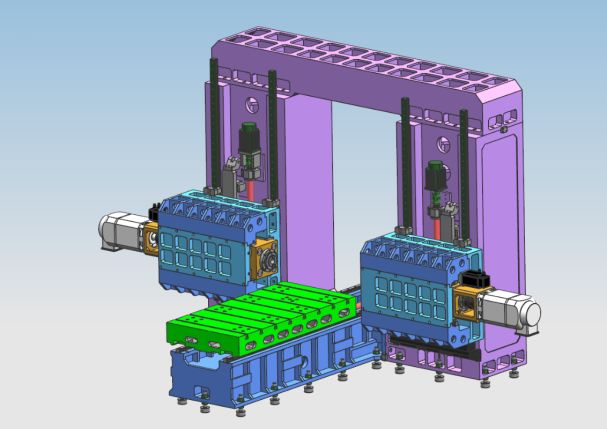

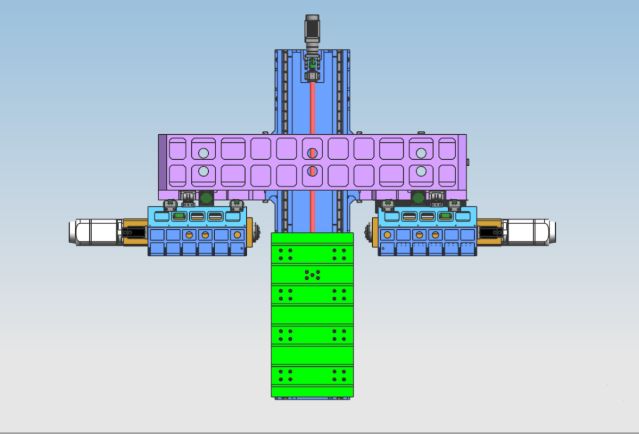

Ibhedi, ibhentshi yokusebenzela, iintsika zasekhohlo nasekunene, imiqadi, imiqadi yokudibanisa igantry, iisali, iinkunzi zeegusha, njl.njl., zonke zenziwe ngokubunjwa kwentlabathi yeresin, umgangatho ophezulu wentsimbi engwevu engama-250, ifakwe kumngxuma wentlabathi oshushu → ukuguga kokungcangcazela → ukungcangcazela ukuguga→ukungcangcazela →ukungcangcazela →ukungcangcazela →ukucima eziko→ukungcangcazela ukuguga→ukugqiba, susa ngokupheleleyo uxinzelelo olubi lwamalungu, nokugcina ukusebenza kwamalungu kuzinzile. Ibhedi esisigxina, iikholomu ezisekhohlo nasekunene, i-gantry, kunye ne-workbench move; Umatshini unokugaya, ukusika, ukugawula, ukucwiliswa, ukucofa kunye neminye imisebenzi, indlela yokupholisa isixhobo kukupholisa kwangaphandle, uMshini uqulethe i-axes ye-5 yokutya, enokuqonda ukudibanisa kwe-4-axis, i-5-axis single-action, iintloko zamandla ezi-2. , iMachine axial kunye Intloko yamandla iboniswe kumzobo ongezantsi.

2.2. Isakhiwo esiphambili se-axial transmission feed part

2.2.1. I-X-axis: I-worktable iphinda ibuyele ecaleni ecaleni komgaqo kaloliwe webhedi esisigxina.

Ukuhanjiswa kwe-X-axis: I-AC servo motor kunye ne-high-precision i-planetary reducer isetyenziselwa ukuqhuba i-worktable ngokusebenzisa i-ball screw transmission ukuqonda i-X-axis linear motion.

Ifomu yesikhokelo sikaloliwe: beka iileyili ezimbini zesikhokelo ezichanekileyo ezichanekileyo

2.2.2.Y1 i-axis: Intloko yamandla kunye nenkunzi yegusha zifakwe ngokuthe nkqo kwicala langaphambili lekholamu, kwaye zibuyisela ngasekhohlo nasekunene ecaleni komgaqo kaloliwe wekholamu.

Ukuhanjiswa kwe-Y1-axis: I-AC servo motor isetyenziselwa ukuqhuba i-screw yebhola ukuze iqhube isali ukuze ihambe, kwaye iqonde i-Y1-axis intshukumo yomgca.

Ifom yesikhokelo sikaloliwe: Iziqwenga ezi-4 ze-45 uhlobo lweereyile zesikhokelo ezihambelanayo.

2.2.3.Y2 i-axis: Inkunzi yegusha yesibini yentloko yamandla ifakwe ngokuthe nkqo kwicala langaphambili lekholamu, kwaye ibuyisela ngasekhohlo nasekunene ecaleni komgaqo kaloliwe wekholamu.

Ukuhanjiswa kwe-Y2-axis: I-AC servo motor isetyenziselwa ukuqhuba i-screw yebhola ukuqhuba intshukumo yesali ukuze iqonde intshukumo yomgca we-Y1-axis.

Ifom yesikhokelo sikaloliwe: Iziqwenga ezi-4 ze-45 uhlobo lweereyili zesikhokelo esinemigca

2.2.4. I-axis ye-Z1: I-saddle ye-sliding yentloko yamandla ifakwe ngokuthe nkqo kwicala langaphambili lekholamu yasekunene, kwaye iphinda ibuyele phezulu nasezantsi ecaleni komgaqo kaloliwe wekholamu.

Ukuhanjiswa kwe-Z1-axis: I-AC servo motor kunye ne-high-precision i-planeter reducer isetyenziselwa ukuqhuba inkunzi yegusha ukuba ihambe nge-screw yebhola ukuze iqonde i-Z1-axis ye-linear motion.

Ifom yesikhokelo sikaloliwe: I-2 65 yohlobo lweereyili zesikhokelo ezihambelanayo

2.2.5.Z2 i-axis: Isali yesilayidi yentloko yamandla ifakwe ngokuthe nkqo kwicala langaphambili lekholamu yasekunene, kwaye iphinda ibuyele phezulu nasezantsi ecaleni komzila kaloliwe wekholamu.

Ukuhanjiswa kwe-Z1-axis: I-AC servo motor kunye ne-high-chane-chane isinciphisi seplanethi isetyenziselwa ukuqhuba inkunzi yegusha ukuba ihambe nge-screw yebhola ukuze iqonde i-Z2-axis-linear motion.

Ifom yesikhokelo sikaloliwe: I-2 65 yohlobo lweereyili zesikhokelo ezihambelanayo

Umgangatho ophakamileyo we-HT250 wekholamu yokuphosa 2 iziqwenga ze-65 uhlobo olunzima-umsebenzi wemigca yesikhokelo somzila

Intloko yamandla enesithukuthezi kunye nokugaya (kubandakanywa nentloko yamandla 1 kunye ne-2) yinqama yesikwere edibeneyo, kwaye isalathiso esihambayo sikhokelwa yimizila ye-4 ye-roller guide. I-drive isebenzisa i-AC servo motor ukuqhuba i-precision ibhola screw pair. Umatshini uxhotyiswe ngebhari ye-nitrogen balance. , Ukunciphisa umthamo wokuthwala wentloko yomatshini kwi-screw kunye ne-servo motor. Injini ye-Z-axis inomsebenzi wokuqhawuka oluzenzekelayo. Kwimeko yokusilela kwamandla, i-automatic brake iya kubamba i-motor shaft ngokuqinileyo ukuze ingakwazi ukujikeleza. Xa usebenza, xa i-drill bit ingabambi i-workpiece, iya kutya ngokukhawuleza; xa i-drill bit ichukumisa i-workpiece, iya kutshintshela ngokuzenzekelayo kwisondlo esisebenzayo. Xa i-drill bit ingena kwi-workpiece, iya kutshintshela ngokuzenzekelayo kwi-rewind ngokukhawuleza; xa isiphelo se-drill bit sishiya i-workpiece kwaye sifikelele kwindawo emiselweyo, iya kuhamba kwindawo elandelayo yomngxuma ukuqonda ukujikeleza okuzenzekelayo. Kwaye inokuqonda imisebenzi yokwemba umngxuma oyimfama, ukugaya, ukubetha, ukuqhekeza itshiphu, ukususwa kwetshiphu ngokuzenzekelayo, njl., ephucula imveliso yabasebenzi.

I-500mm ye-stroke ekhompawundi yesikwere intloko yamandla enkunzi yegusha isebenzisa izikhokelo ezinomgca endaweni yofakelo lwemveli ukuphucula kakhulu ukuchaneka kwesikhokhelo ngelixa igcina ukuqina kwenkunzi yegusha.

2.3. Ukususwa kwe-chip kunye nokupholisa

Kukho izihambisi zetshiphu ezijikelezayo kunye nezisicaba ezifakwe kumacala omabini phantsi kwebhentshi yokusebenza, kwaye iitshiphusi zinokugqithiselwa ngokuzenzekelayo kumhambisi wetshiphu ekugqibeleni ngezigaba ezibini zokujikeleza kunye neepleyiti zetyathanga ukuqonda imveliso ephucukileyo. Kukho impompo yokupholisa kwitanki yokupholisa yokuhambisa itshiphu, engasetyenziselwa ukupholisa kwangaphandle kwesixhobo ukuqinisekisa ukusebenza kunye nobomi benkonzo yesixhobo, kwaye into yokupholisa inokuphinda isetyenziswe.

3. Inkqubo yolawulo lwamanani edijithali epheleleyo:

3.1. Ngomsebenzi wokuqhekeka kwetshiphu, ixesha lokuqhekeka kwetshiphu kunye nomjikelo wokuqhekeka kwetshiphu unokusetwa kujongano lomatshini womntu.

3.2. Ukuxhotyiswa ngesixhobo sokuphakamisa isixhobo, umgama wokuphakamisa isixhobo unokusetwa kwi-interface yomatshini wendoda. Xa umgama ufinyelelwe, isixhobo siphakanyiswa ngokukhawuleza, emva koko ii-chips ziphonswa kude, kwaye emva koko zithunyelwa ngokukhawuleza kwindawo yokugaya kwaye ziguqulelwe ngokuzenzekelayo emsebenzini.

3.3. Ibhokisi yolawulo lokusebenza kwindawo esembindini kunye neyunithi ebanjwa ngesandla yamkele inkqubo yolawulo lwamanani kwaye ixhotyiswe ngojongano lwe-USB kunye nomboniso wekristale engamanzi weLCD. Ukuze kuququzelelwe inkqubo, ukugcinwa, umboniso kunye nonxibelelwano, ujongano lokusebenza lunemisebenzi efana nencoko yababini yomatshini, imbuyekezo yempazamo, kunye ne-alamu ezenzekelayo.

3.4. Isixhobo sinomsebenzi wokujonga kwaye uphinde uhlolisise indawo yomngxuma ngaphambi kokucubungula, kwaye ukusebenza kulula kakhulu.

4. Ukuthambisa okuzenzekelayo

Ukuchaneka komatshini izibini zesikhokelo zikaloliwe ezichanekileyo, izibini ezichanekileyo zebhola kunye nezinye iiperi ezichanekileyo eziphezulu zixhotyiswe ngeenkqubo zokuthambisa ezizenzekelayo. Ipompo yokuthambisa ngokuzenzekelayo ikhupha i-oyile yoxinzelelo, kwaye igumbi le-oyile ye-lubricator yobungakanani ingena kwioyile. Emva kokuba igumbi leoli lizaliswe ngeoli, xa uxinzelelo lwenkqubo luphakama ukuya kwi-1.4-1.75Mpa, ukutshintshwa koxinzelelo kwinkqubo ivaliwe, ipompo iyayeka, kwaye i-valve yokukhulula ikhupha ngexesha elifanayo. Xa uxinzelelo lwe-oyile kwindlela yehla ngaphantsi kwe-0.2Mpa, i-lubricator yobungakanani iqala ukuzalisa indawo yokuthambisa kwaye igqibe ukuzaliswa kweoli enye. Ngenxa yokunikezelwa kweoyile echanekileyo yomthamo we-oyile kunye nokufunyanwa koxinzelelo lwenkqubo, unikezelo lweoyile luthembekile, luqinisekisa ukuba kukho ifilimu yeoli kumphezulu wesibini ngasinye sekinematic, ukunciphisa ukungqubana kunye nokunxiba, kunye nokuthintela umonakalo isakhiwo sangaphakathi esibangelwa kukufudumala. , ukuqinisekisa ukuchaneka kunye nobomi boMshini. Xa kuthelekiswa nesibini sesikhokelo sokutyibilika sikaloliwe, isibini esiqengqelekayo sesikhokelo sikaloliwe esisetyenziswa kulo Mashini sinothotho lweenzuzo:

①Uvakalelo lwentshukumo luphezulu, i-coefficient ye-friction ye-rolling guide rail incinci, kuphela i-0.0025 ~ 0.01, kwaye amandla okuqhuba ayancipha kakhulu, alingana ne-1/10 yoomatshini abaqhelekileyo.

② Umahluko phakathi kwengxabano eguqukayo kunye ne-static incinci kakhulu, kwaye ukusebenza okulandelayo kugqwesileyo, oko kukuthi, ixesha lekhefu phakathi komqondiso wokuqhuba kunye nesenzo soomatshini sifutshane kakhulu, esilungele ukuphucula isantya sokuphendula kunye novakalelo lwe inkqubo yolawulo lwamanani.

③Ilungele intshukumo yomgca enesantya esiphezulu, kwaye isantya sayo esikhawulezileyo simalunga namaxesha ali-10 aphezulu kunoololiwe besikhokelo sokutyibilika.

④ Inokuqonda intshukumo engenasikhewu kwaye iphucule ukuqina kwentshukumo yenkqubo yoomatshini.

⑤Iveliswe ngabavelisi abaqeqeshiweyo, inokuchaneka okuphezulu, ukuguquguquka okuhle kunye nokugcinwa lula.

5.Ukuhlolwa kwelaser ene-axis ezintathu:

Umatshini ngamnye we-Bosman ulinganiswe yi-laser interferometer yenkampani ye-RENISHAW e-United Kingdom ukuhlola ngokuchanekileyo kunye nokubuyekeza impazamo ye-pitch, ukubuyisela umva, ukuchaneka kwendawo, ukuphindaphinda ukuchaneka kokumisa, njl. umatshini . Ukuhlolwa kwe-Ballbar Umatshini ngamnye usebenzisa i-ballbar evela kwinkampani yaseBritani ye-RENISHAW ukulinganisa ukuchaneka kwesangqa sokwenyani kunye nokuchaneka komatshini wejometri, kunye nokuqhuba iimfuniselo zokusika kwisetyhula ngaxeshanye ukuze kuqinisekiswe ukuchaneka komatshini we-3D kunye nokuchaneka kwesetyhula kumatshini.

6. Indawo yokusetyenziswa komatshini:

6.1. Iimfuno zokusingqongileyo zokusetyenziswa kwezixhobo

Ukugcina iqondo elingaguqukiyo lobushushu be-ambient yinto eyimfuneko kumatshini ochanekileyo.

(1) Iimfuno ezifumanekayo zobushushu bendawo yi-10°C ukuya kuma-35°C, xa iqondo lobushushu lendawo liku-20°C, ukufuma kufuneka kube ngama-40% ukuya kuma-75%.

(2) Ukuze kugcinwe ukuchaneka kwe-static yoMshini ngaphakathi koluhlu oluchaziweyo, ubushushu obuphezulu be-ambient kufuneka bube yi-15 ° C ukuya kwi-25 ° C, kwaye umahluko weqondo lokushisa awuyi kudlula ± 2 ° C / 24h.

6.2. Amandla ombane ombane: izigaba ezi-3, i-380V, ngaphakathi koluhlu lwe-± 10% yokutshintsha kombane, i-frequency supply frequency: 50HZ.

6.3. Ukuba i-voltage kwindawo yokusetyenziswa ayizinzile, uMshini kufuneka uxhotyiswe ngamandla ombane ozinzileyo ukuqinisekisa ukusebenza okuqhelekileyo koMshini.

6.4. Umtshini kufuneka ube nesiseko esithembekileyo: ucingo lokumisa lucingo lobhedu, ububanzi bocingo akufunekanga lube ngaphantsi kwe-10mm², kwaye ukuxhathisa umhlaba kufuneka kube ngaphantsi kwe-4 ohms.

6.5. Ukuze kuqinisekiswe ukusebenza okuqhelekileyo kwezixhobo zokusebenza, ukuba umoya ocinezelweyo womthombo womoya awukwazi ukuhlangabezana neemfuno zomthombo womoya, isethi yesixhobo sokucoca umthombo womoya (i-dehumidification, degreasing, filtering) kufuneka yongezwe ngaphambi kokungena komoya. yoMshini.

6.6. Gcina izixhobo kude nelanga elithe ngqo, ukungcangcazela kunye nemithombo yobushushu, iijenereyitha ezihamba rhoqo, oomatshini bokudibanisa umbane, njl.

7.Iiparamitha zoBugcisa:

| Umzekelo | 5020-5Z | |

| Ubungakanani bobungakanani bomsebenzi wokusetyenzwa | Ubude × ububanzi × ubude (mm) | 5000×2000×2500 |

| Isondlo esiphezulu seGantry | Ububanzi (mm) | 2300 |

| ubungakanani bedesika esebenzayo | Ubude X Ububanzi (mm) | 5000*2000 |

| Uhambo lwetafile | Ibhentshi yokusebenzela ibuyela emva naphambili (mm) | 5000 |

| Inkunzi yegusha ephindwe kabini phakamisa kwaye ezantsi | Ukubetha phezulu naphantsi kwenkunzi yegusha (mm) | 2500 |

| Uhlobo lwenkunzi yegusha ethe tye yokomba intloko yamandla entloko enye ezimbini | Ubuninzi (2) | 2 |

| Uhlobo lwenkunzi yegusha ethe tye yokomba intloko yamandla entloko enye ezimbini | I-Spindle taper | BT50 |

| Isantya sokujikeleza (r/min) | 30~5000 | |

| Amandla e-Servo spindle motor (kw) | 37*2 | |

| Umgama phakathi kwamaziko eziphelo zempumlo zezijikelezi-langa ezimbini (mm) | 1500-2500mm | |

| Ukubetha kwasekhohlo nasekunene kwenkunzi yegusha enye (mm) | 500 | |

| Ukubetha kwasekhohlo nasekunene kwenkunzi yegusha ephindwe kabini (mm) | 1000 | |

| Ukuchaneka kokuma kweBidirectional | 300mm*300mm | ±0.025 |

| Ukuchaneka kokumisa okuphindwe kabini | 300mm*300mm | ±0.02 |

| Ubunzima obupheleleyo (t) | (malunga) nama-55 | Ubunzima obupheleleyo (t) |