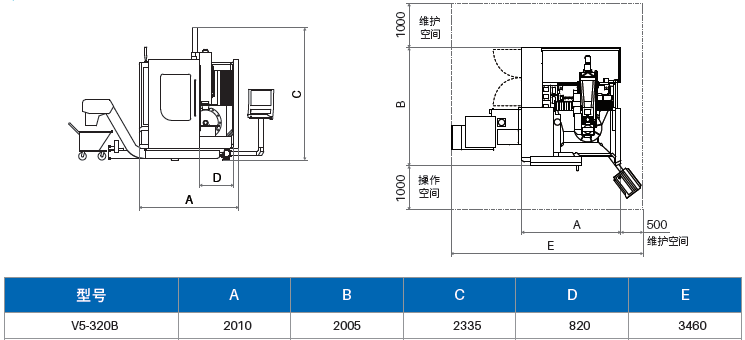

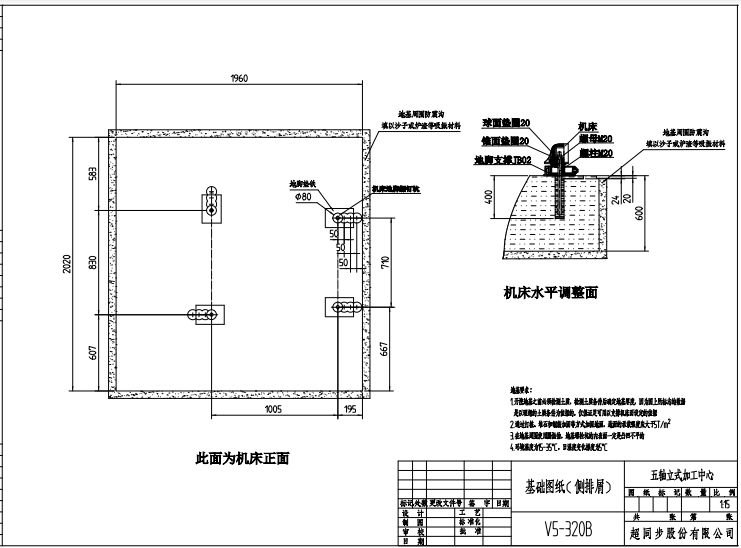

5-Axis nkqo Machining Centre V5-320B

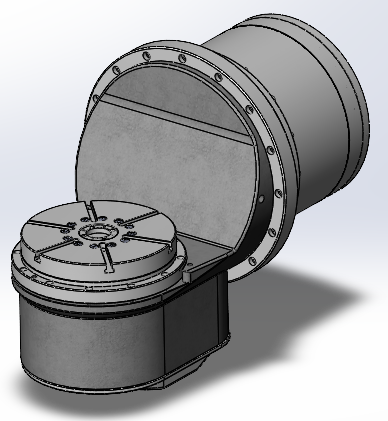

1. Uyilo lonke lwesixhobo somatshini

I-V5-320B i-five-axis machining center ithatha isakhiwo esime kakuhle se-C, ikholamu igxininiswe ebhedini, ipleyiti yesilayidi ihamba ngokuthe tye kwikholamu (i-X direction), isihlalo sesilayidi sihamba ngobude kunye nepleyiti yesilayidi (ulwalathiso lwe-Y ), kwaye i-headstock ihamba ngokuthe nkqo ecaleni kwesitulo sesilayidi (i-Z direction). Itheyibhile yokusebenza ithatha i-self-developed direct-drive single-arm cradle structure, kunye nezalathi zayo ezahlukeneyo zokusebenza zifikelele kwinqanaba eliphezulu lamazwe ngamazwe.

2. Inkqubo yokutya

I-X, Y, i-Z-axis linear guide rails kunye nezikrufu zebhola, i-friction encinci kunye ne-static, uvakalelo oluphezulu, i-vibration encinci ye-speed high-speed, akukho zinambuzane ngesantya esiphantsi, ukuchaneka kwendawo ephezulu, kunye nokusebenza okugqwesileyo kwe-servo drive.

I-X, Y, i-Z-axis servo motors idibaniswe ngokuthe ngqo kunye nezikrufu zebhola ezichanekileyo ngokudibanisa, ukunciphisa amakhonkco aphakathi, ukuqonda ukuhanjiswa kwe-gapless, ukutya okuguquguqukayo, ukubeka ngokuchanekileyo, kunye nokuchaneka kokuhanjiswa okuphezulu.

I-Z-axis servo motor inomsebenzi wokuqhawula. Xa kwenzeka ukusilela kwamandla, i-brake inokubamba ngokuzenzekelayo i-motor shaft ngokuqinileyo ukuze ingakwazi ukujikeleza, edlala indima yokukhusela ukhuseleko.

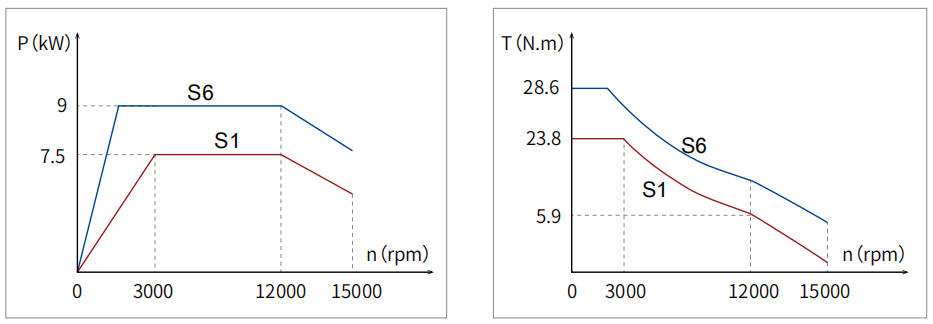

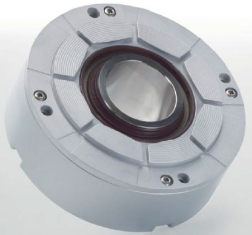

3. I-spindle yombane

I-spindle yombane ithatha i-self-developed high-performance spindle yombane (i-patent yokuqamba: 202010130049.4), kwaye isiphelo sixhotyiswe ngemibhobho yokupholisa ukupholisa isixhobo. Ineenzuzo zesantya esiphezulu, ukuchaneka okuphezulu, kunye nokuphendula okuphezulu okuguquguqukayo, kwaye inokuqonda ummiselo wesantya esingenanyathelo. I-encoder eyakhelwe-ngaphakathi yokuchaneka okuphezulu inokuqonda indlela echanekileyo yokumisa kunye nokucofa okuqinileyo.

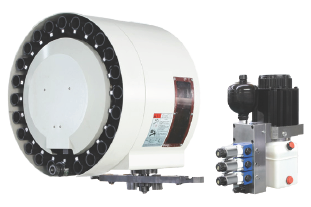

4. Imagazini yesixhobo

BT40 idiskhi uhlobo isixhobo magazini, 24 izithuba isixhobo, utshintsho isixhobo oluzenzekelayo yi ATC manipulator.

Bona ngezantsi:

5. Turntable

Yamkela i-self-developed direct-drive-single-arm cradle structure, enenzuzo yokuqina okuphezulu, ukuchaneka okuphezulu kunye nokuphendula okuphezulu okuguquguqukayo.

| I-axis | Ilinganiswe ngeTorque Nm | Ilinganiswe Isantya rpm | Max. Isantya rpm | Ilinganiswe ngoku A | Ilinganiswe Amandla kW |

| B | 656 | 80 | 100 | 18 | 5.5 |

| C | 172 | 100 | 130 | 6.1 | 1.8 |

6. Inkqubo yempendulo yelophu evaliwe ngokupheleleyo

I-X, Y, kunye no-Z ii-axes zomgca zixhotyiswe nge-HEIDENHAIN LC4 uthotho lwemilinganiselo yexabiso elipheleleyo lokulinganisa; Iitafile ze-B kunye ne-C ezijikelezayo zixhotyiswe nge-HEIDENHAIN RCN2000 uthotho lwee-encoder ze-encoder zexabiso elipheleleyo ukuze zibone ingxelo evaliweyo-evaliweyo yee-axes ze-5 zokutya, ukuqinisekisa ukuba isixhobo somatshini sinokuchaneka okuphezulu kunye nokuchaneka okuphezulu. ukugcinwa kokuchaneka.

7. Inkqubo yokupholisa kunye ne-pneumatic

Ixhotyiswe ngesipholisi samanzi sokupholisa ubushushu obuqhubekayo ukuqinisekisa ukuba i-spindle yombane kunye ne-turntable drive ejikelezayo ikwimeko efanelekileyo yokusebenza kwaye inokuhamba ngokufanelekileyo ixesha elide.

Inkqubo ye-pneumatic ihluzwa ngamacandelo e-pneumatic ukuqonda imisebenzi yokucoca kunye nokuvuthela umngxuma we-taper we-shaft engundoqo, ukukhuselwa kokutywinwa kwe-air ye-bearing shaft engundoqo, kunye nokuguqula imagazini yesixhobo kunye nomphathi wesixhobo.

8. Inkqubo yokuthambisa ephakathi

Ibhloko yesilayidi somzila wesikhokelo kunye ne-nut ye-screw yebhola yamkela isixhobo sokuthambisa esisembindini esinegrisi ebhityileyo, ebonelela ngokuthambisa rhoqo kunye nobuninzi bokuqinisekisa ukuchaneka kunye nokuzinza kwe-screw yebhola kunye nesikhokelo sikaloliwe.

9. Inkqubo yokulinganisa iworkpiece

Isixhobo somatshini sixhotyiswe nge-HEIDENHAIN TS460 yokuchukumisa iprobe kunye ne-wireless signal receiver, enokufakwa kwi-spindle nge-manual okanye inkqubo yokutshintsha isixhobo esizenzekelayo ukuqonda imisebenzi yokulungelelaniswa komsebenzi, umlinganiselo we-workpiece kunye nokusetwa kwangaphambili kwendawo, kunye nokuphindaphinda komlinganiselo ≤ I-1um (isantya sokuhlola i-1 m/min), iqondo lobushushu elisebenzayo liyi-10°C ukuya kuma-40°C. I-HEIDENHAIN yokuchukumisa iprobe iqalwa lutshintsho lokukhanya. I-stylus isebenzisa ii-bearings ezintathu ukuqinisekisa indawo efanelekileyo ye-free state. Ayinxibi ngexesha lokusetyenziswa, inokuphinda iphindwe kwaye izinzile ixesha elide.

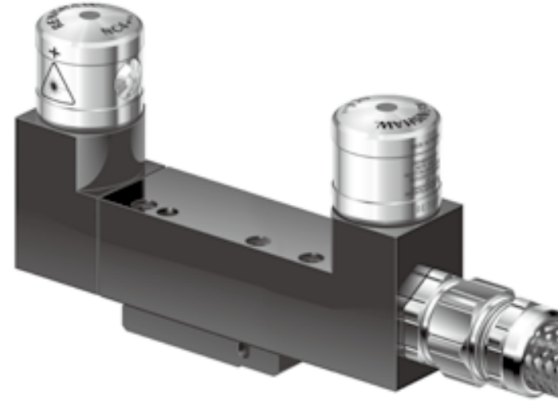

10. Inkqubo yokulinganisa isixhobo

Isixhobo somatshini sixhotyiswe nge-Renishaw NC4 isixhobo sokubeka isixhobo se-laser, ukuphindaphindwa kokulinganisa ngu-± 0.1um, kunye nokushisa okusebenzayo yi-5 ° C ukuya kwi-50 ° C.

11. Ulungelelwaniso oluchanekileyo lwe-axis ezintlanu

Isixhobo somatshini sixhotyiswe ngeebhola zokulinganisa i-KKH ezivela kwi-HEIDENHAIN, kunye ne-TS series probes, ukufezekisa ukulinganisa ngokuchanekileyo kwe-axis yokujikeleza kwesixhobo somatshini, ukunciphisa iimpazamo ngexesha lokuhamba kwesixhobo somatshini, kunye nokufezekisa ukuchaneka okuphezulu kunye nokuphindaphinda okuphezulu.

12. Ukukhusela isixhobo somatshini

Isixhobo somatshini samkela isigqubuthelo sokhuselo esidibana nemigangatho yokhuseleko ukunqanda ukupholisa kunye neetshiphusi ekutshizeni, ukuqinisekisa ukusebenza okukhuselekileyo, kunye nenkangeleko emnandi. Isalathiso se-X sesixhobo somatshini sixhotyiswe ngesikhuselo sezixhobo, esinokukhusela ngokufanelekileyo umzila wesikhokelo kunye nebhola lebhola.

13. Iimeko zokusebenza zesixhobo somatshini

(1) Umbane: 380V±10% 50HZ±1HZ isigaba sesithathu se-AC

(2) Ubushushu bommandla: 5°C-40°C

(3) Elona qondo lobushushu: 22°C-24°C

(4) Ukufuma okuhambelanayo: 20-75%

(5) Uxinzelelo lomthombo womoya: ≥6 ibha

(6) Izinga lokuhamba komthombo wegesi: 500 L / min

14. Ukuqaliswa komsebenzi wenkqubo ye-CNC

I-HEIDENHAIN TNC640 inkqubo ye-CNC

(1) Inani leezembe: ukuya kuthi ga kwi-24 loops yokulawula

(2) Uguqulelo lwesikrini sokuchukumisa kunye nokusebenza kokuchukumisa okuninzi

(3) Igalelo leNkqubo: Incoko yeKlartext kunye nekhowudi ye-G (ISO) inkqubo

4

(5) Imijikelo eninzi yokugaya nokugrumba

(6) Imbuyekezo yesixhobo: imbuyekezo yeradiyasi yesixhobo kunye nembuyekezo yobude besixhobo. Umjikelo wophando

(7) Ukusika idatha: Ukubala ngokuzenzekelayo kwesantya sokuphotha, isantya sokusika, ukondla nge-blade nganye kunye nokutya ngesangqa

8

(9) I-Parallel Run: Inkqubo enenkxaso yemizobo ngelixa enye inkqubo isebenza

(10)Iziqalelo zeContour: umgca othe tye/i-chamfer/i-arc indlela/iziko lesangqa/iradiyasi yesangqa/i-arc eqhagamshelwe ngokuthe tye/ikona engqukuva

(11) Ukusondela kunye nokusuka kwiicontours: tangential okanye perpendicular / ngokusebenzisa iindlela zearc

(12) Inkqubo jump: subroutine/program block ukuphinda/nayiphi na inkqubo inokuba yi-subroutine

(13) Umjikelo weenkonkxa: ukubhola, ukucofa (kunye okanye ngaphandle kwesakhelo sokucofa esidadayo), uxande kunye ne-arc cavity. Ukugrumba i-Peck, ukubuyisela kwakhona, ukudika, ukujonga indawo, ukugrumba indawo. Ukugaya imisonto yangaphakathi nangaphandle. Ukurhabaxa kweendawo ezithe tyaba nezithambekileyo. Gqibezela i-machining yeepokethi ezixande kunye nesetyhula, abaphathi bexande kunye nesetyhula. Imijikelo erhabaxa kunye nokugqiba kwigrooves ethe tye kunye nesetyhula. Hlela amanqaku kwizangqa kunye nemigca. Indawo yoluhlu: Ikhowudi yeQR. Ikhonkco leContour, ipokotho yeContour. I-Contour groove ye-trochoidal milling. Umjikelo wokukrola: krola umbhalo okanye amanani ngomgca othe ngqo okanye i-arc.

(14) Lungelelanisa inguqu: ukuguqulela, ukujikeleza, isipili, ukulinganisa (i-axis ethile).

(15) Q inkqubo eguquguqukayo yeparamitha: umsebenzi wezibalo, ukusebenza ngokwengqiqo, ukusebenza kwabazali, ixabiso elipheleleyo, rhoqo þ, ukuchasa, inani elipheleleyo okanye idesimali, umsebenzi wokubala isangqa, umsebenzi wokulungisa umbhalo.

(16) Uncedo lwenkqubo: ikhaltyhuleyitha. Uluhlu lwayo yonke imiyalezo yemposiso yangoku. Umsebenzi woncedo womxholo-obuthathaka kwimiyalezo yemposiso. TNCguide: inkqubo yoncedo edibeneyo; i-TNC 640 ibonisa ulwazi olusuka ngqo kwincwadi yomsebenzisi. Inkxaso yegraphical programming yomjikelo. Iibhloko zezimvo kunye neebhloko eziphambili kwiinkqubo zeNC.

(17) Ukufumana ulwazi: sebenzisa ngokuthe ngqo indawo yokwenene kwiprogram yeNC.

(18) Imizobo yokuqinisekiswa kwenkqubo: Ukulinganisa okubonakalayo kwemisebenzi yomatshini kunokwenziwa nangona enye inkqubo isebenza. Umbono ophezulu / umbono we-dimensional ezintathu / umbono westereo, kunye ne-inclined processing plane/3-D umzobo womgca. Ukukala kwendawo.

(19) Inkxaso yemizobo yenkqubo: Nokuba enye inkqubo iyasebenza, imizobo (i-2-D yesandla somzobo wokulandela umzobo) yecandelo lenkqubo ye-NC yegalelo inokuboniswa kwindlela yokusebenza yokuhlela inkqubo.

(20) Inkqubo eqhuba imizobo: i-real-time graphics simulation ngelixa kusenziwa inkqubo yokugaya. umbono ophezulu/umbono wesithathu/umbono westereo.

(21) Ixesha lokucubungula: Bala ixesha lokucubungula kwimodi yokusebenza "yovavanyo". Ibonisa ixesha lomatshini langoku kwimodi yokusebenza ye "Program Run".

(22) Buyela kwi-contour: bonisa ixesha langoku lokucubungula kwimodi yokusebenza "yenkqubo esebenzayo". Ukuphazamiseka kweprogram, ukushiya kunye nokubuyela kwi-contour.

(23) Ulawulo lwamanqaku angaphambili: itafile yokugcina nayiphi na indawo esetwe kwangaphambili.

(24) Itheyibhile yemvelaphi: iitheyibhile ezininzi zemvelaphi, ezisetyenziselwa ukugcina imvelaphi ehambelana nomsebenzi.

(25) I-3-D Machining: Ukulawulwa kweMotion of High Quality Smooth Jerk

(26) Ixesha lokucubungula ibhlokhi: 0.5 ms

(27) Isisombululo segalelo kunye nenyathelo lokubonisa: 0.1 μm

(28) Umjikelo wokulinganisa: ulungelelwaniso lweprobe. Imbuyekezo eyenziwa ngesandla okanye ezenzekelayo yokungalungelelaniswa kwepiece workpiece. Cwangcisa amanqaku asetwe kwangaphambili ngesandla okanye ngokuzenzekelayo. Isixhobo kunye nomsebenzi unokulinganiswa ngokuzenzekelayo.

(29) Imbuyekezo yempazamo: impazamo ye-axis yomgca kunye ne-nonlinear, i-backlash, i-angle ebukhali e-reverse ye-circular motion, i-reverse error, ukwandiswa kwe-thermal. ukukhuhlana okumileyo, ukukhuhlana okutyibilikayo.

(30) Ujongano lwedatha: RS-232-C/V.24, ukuya kuthi ga kwi-115 kbit / s. Ujongano lwedatha olwandisiweyo lweprotocol ye-LSV2, sebenzisa i-HEIDENHAIN TNCremo okanye isoftware ye-TNCremoPlus ukuze isebenze ukude i-TNC ngokusebenzisa le data interface. 2 x Gigabit Ethernet 1000BASE-T ujongano. Izibuko ze-5 x ze-USB (i-1 yangaphambili ye-USB 2.0 port, i-4 USB 3.0 port).

(31) Uxilongo: Izixhobo zokuxilonga ezizimeleyo zokusombulula ingxaki ngokukhawuleza kwaye kulula.

(32) Umfundi we-CAD: bonisa iifayile zefomethi ye-CAD eqhelekileyo.

Eyona parameter

| Into | Iyunithi | Ipharamitha | |

| Itafile yokusebenza | Idayamitha enokusetyenzwa | mm | 320 |

| Ubuninzi bomthwalo othe tye | kg | 150 | |

| Ubungakanani bomthwalo othe nkqo | kg | 100 | |

| T-slot | mm | 8X10H8 | |

| Uluhlu lokuqhubekekisa | Umgama phakathi kobuso besiphelo se-spindle kunye nobuso besiphelo setable (Max) | mm | 430 |

| Umgama phakathi kobuso besiphelo se-spindle kunye nobuso besiphelo setable (Min) | mm | 100 | |

| Umgca we-X | mm | 450 | |

| Umgca we-Y | mm | 320 | |

| Umgca weZ | mm | 330 | |

| Umgca we-B | ° | -35 ° ~+ 110 ° | |

| Umgca weC | ° | 360 ° | |

| I-spindle | Taper(7 ∶ 24) |

| BT40 |

| Isantya esilinganiselwe | rpm | 3000 | |

| Max. isantya | rpm | 15000 | |

| Ilinganiswe ngetorque S1 | Nm | 23.8 | |

| Ilinganiswe Amandla S1 | KW | 7.5 | |

|

I-axis | X axis Rapid ukunqumla isantya | m/umz | 36 |

| I-Y axis Isantya sokunqumla ngokukhawuleza | m/umz | 36 | |

| Z axis Rapid ukunqumla isantya | m/umz | 36 | |

| Umgca we-B Max. isantya | rpm | 130 | |

| Umgca we-C umgca. isantya | rpm | 130 | |

| Imagazini yesixhobo | Uhlobo |

| Uhlobo lwediski |

| Indlela yokukhetha isixhobo |

| Ukhetho lwesixhobo esikufutshane macala omabini | |

| Umthamo | T | 24 | |

| Max. ubude besixhobo | mm | 150 | |

| Max. ubunzima besixhobo | kg | 7 | |

| Max. umsiki wediskhi idayamitha (Isixhobo esipheleleyo) | mm | 80 | |

| Ubuninzi bediskhi yomsiki wedayamitha (Isixhobo esisecaleni esingenanto) | mm | 150 | |

| Ukuchaneka | Umgangatho olawulayo |

| I-GB/T20957.4(ISO10791-4) |

| I-X-axis/Y-axis/Z-axis yokuchaneka kokuma | mm | 0.008/0.008/0.008 | |

| I-B-axis / i-C-axis yokumisa ukuchaneka |

| 7”/7” | |

| X-axis/Y-axis/Z-axis phinda ukuchaneka kokuma | mm | 0.006/0.006/0.006 | |

| I-B-axis/C-axis iphinda ukuchaneka kokumisa |

| 5”/5” | |

| Ubunzima bomatshini | Kg | 5000 | |

| Umthamo opheleleyo wombane | KVA | 45 | |

Uluhlu loLungiselelo olusemgangathweni

| Hayi. | Igama |

| 1 | Amacandelo aphambili (kubandakanya ibhedi, ikholamu, ipleyiti yesilayidi, isitulo sesilayidi, isitokhwe sentloko) |

| 2 | X, Y, Z inkqubo yefidi ye-axis ezintathu |

| 3 | I-Single arm cradle turntable |

| 4 | I-spindle yombane BT40 |

| 5 | Inkqubo yokulawula umbane (kubandakanywa nekhabhinethi yombane, imodyuli yombane, imodyuli ye-servo, i-PLC, iphaneli yokusebenza, umboniso, iyunithi ephathwayo, i-air conditioner yekhabhinethi yombane, njl. |

| 6 | Isikali sokulinganisa: HEIDENHAIN |

| 7 | Inkqubo ye-hydraulic |

| 8 | Inkqubo ye-pneumatic |

| 9 | Inkqubo yokuthambisa esembindini |

| 10 | Umhambisi wetshiphu, itanki yamanzi, umqokeleli wetshiphu |

| 11 | Umlindi kaloliwe |

| 12 | Isixhobo somatshini sokhuselo olupheleleyo |

| 13 | Isixhobo sokulinganisa i-Workpiece: HEIDENHAIN TS460 |

|

| Izikali zomgca HEIDENHAIN |

| 14 | Isixhobo sokumisela isixhobo: HEIDENHAIN NC4 |

| 15 | Ulungelelwaniso oluchanekileyo lwe-axis emihlanu: HEIDENHAIN KKH |

| 16 | Ngokusekwe kwindawo enye yokusetyenziswa kwesoftware ye-HPMILL emva kokulungiswa, bopha idilesi yendawo yekhompyuter |

| 17 | Umsebenzi wembuyekezo wobude bobushushu obusontayo |