UMsebenzi oMnzi weCNC woKumba uMshini wokuSila

CNC Drilling kunye Milling Machine

Isantya esiphezulu se-CNC sokomba kunye nomatshini wokusila

Ukusetyenziswa komatshini

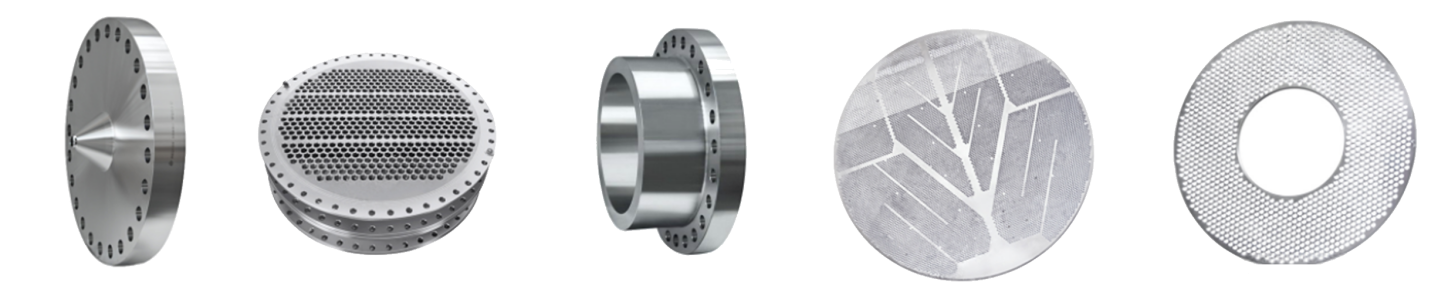

I-CNC yokugrumba kunye noomatshini bokugaya basetyenziselwa ukugrumba okusebenzayo kwezixhobo zokusebenza ezinobunzima ngaphakathi koluhlu olusebenzayo olufana neepleyiti, iiflange, iidiski kunye nezangqa. Ngemingxuma kunye nemingxunya engaboniyo inokugrunjwa kwiintlobo ezahlukeneyo zemathiriyeli. Umatshini ulawulwa ngedijithali kunye nokusebenza lula. Iyakwazi ukufezekisa ukuzenzekelayo, ukuchaneka okuphezulu, iintlobo ezininzi, ukuveliswa kobuninzi.

Ukuze kuhlangatyezwane neemfuno zabasebenzisi abahlukeneyo, inkampani yethu iphuhlise oomatshini abahlukeneyo. Ukongeza kwiimodeli eziqhelekileyo, inokuthi yenziwe ngokwezifiso ngokweemfuno zabathengi.

Ulwakhiwo lomatshini

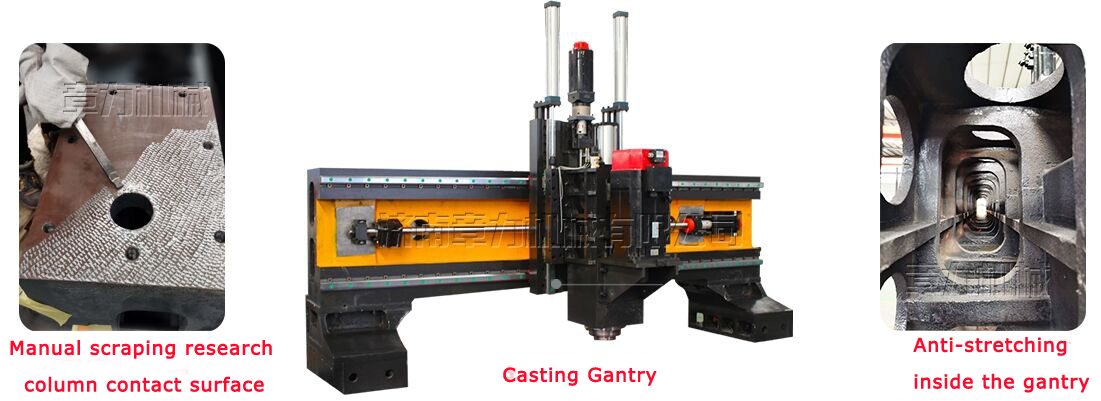

Esi sixhobo ikakhulu siqulunqwe yitafile yebhedi, i-gantry ehambayo, isali yokutyibilika ehambayo, ukubhola kunye ne-spindle yokugaya, isixhobo sokuthambisa esizenzekelayo kunye nesixhobo sokukhusela, isixhobo sokupholisa esijikelezayo, inkqubo yokulawula i-CNC, inkqubo yombane njalo njalo. Ukuxhaswa kunye nokukhokela isikhokelo somgca we-rolling kunye ne-screw drive ye-screw drive echanekileyo, umatshini unokuchaneka kokubeka okuphezulu kunye nokuphindaphinda ukuchaneka kokubeka.

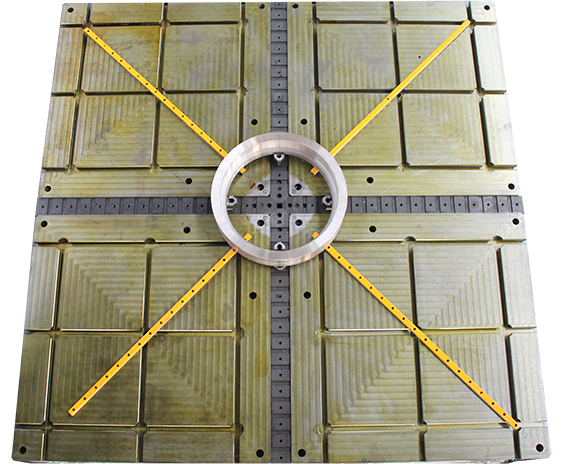

1)Itafile yokusebenza:

Itheyibhile yokusebenza ithatha isakhiwo sokuphosa, kwaye indiza ine-T-slot enengqiqo yokugqiba i-clamping workpieces. Ngaphezulu kwebhedi, ii-T-slots zilungiselelwe. Inkqubo yokuqhuba isebenzisa i-AC servo motor kunye nokuchaneka kwebhola Screw ukuqhuba macala omabini ukwenza i-gantry ihambe kwicala le-Y-axis. Iibholiti ezilungelelanisiweyo zisasazwa phantsi kwebhedi, enokuthi ilungelelanise ngokulula inqanaba letafile yokulala.

2)Movinggantry:

I-gantry ehambayo ifakwe nge-iron 250 engwevu, kunye nezibini ezimbini zesikhokelo somgca we-super-high-capacity zifakwe kwicala langaphambili le-gantry. Iseti echanekileyo ye-screw yebhola kunye ne-servo motor yenza ukuba intloko yamandla isilayidi ihambe kwicala le-X-axis. Intloko yamandla okomba ifakwe kwisilayidi sentloko yamandla. Ukuhamba kwe-gantry kuqondwa yi-servo motor eqhuba ucingo lwebhola kwi-screw yebhola ngokudibanisa ngokuchanekileyo.

3)Movingisali yokutyibilika:

Isali yokutyibilika eshukumayo licandelo lolwakhiwo lwentsimbi echanekileyo. Izilayidi ezimbini ze-NC ze-ultra-high-capacity kunye nesethi ye-screw screw pairs kunye ne-high-precision i-planetary reducer ixhunywe kwi-servo motor ukuqhuba intloko yamandla e-drilling. Ukuhamba kwicala le-Z-axis kunokuqonda ngokukhawuleza ukuya phambili, ukusebenzela phambili, ukubuyisela umva ngokukhawuleza, kunye nokuma kwentloko yamandla. Ngokuqhawuka kwetshiphu ngokuzenzekelayo, ukususwa kwetshiphu, imisebenzi yokumisa ikhefu.

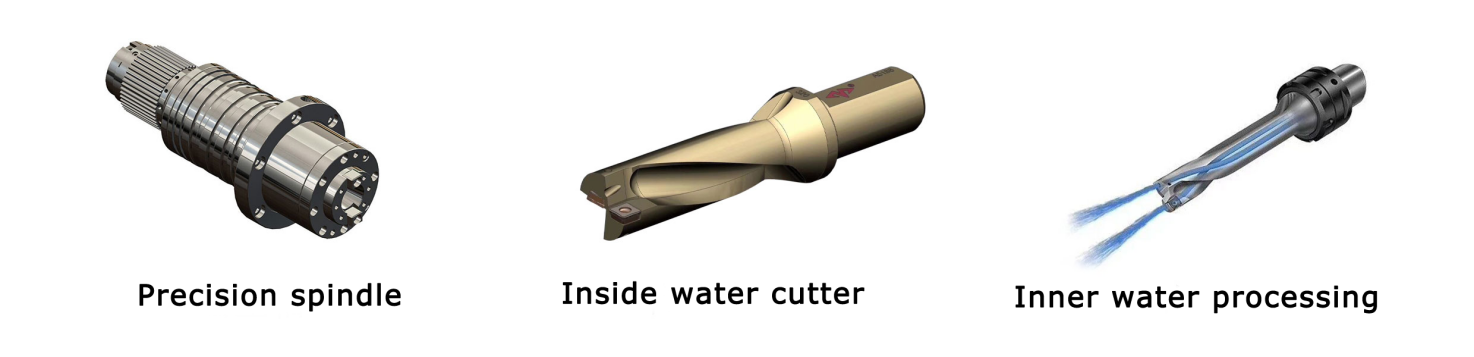

4)Drilling intloko amandla(Spindle):

Intloko yamandla okomba isebenzisa i-servo spindle motor ezinikeleyo, eqhuba i-spindle echanekileyo ngokucokisekileyo ngokuthoba ibhanti le-synchronous ene-toothed ukunyusa i-torque. I-spindle isebenzisa umphambili wesithathu, emibini, kunye nomqolo ontlanu wokuqhagamshelwa kwe-angular yaseJapan ukufikelela kwisantya esingenanyathelo. Ukutshintshwa ngokukhawuleza kunye nokulula, ukutya kuqhutywa yi-servo motor kunye nebhola. Ii-axes ze-X kunye ne-Y zinokudibaniswa, kwaye ulawulo lwe-loop oluvaliweyo oluvaliweyo lusetyenziselwa ukufezekisa imisebenzi ye-interpolation yomgca kunye nesetyhula.

Ukuphela kwe-Spindle yi-BT40 enomngxuma odibeneyo, oxhotyiswe nge-Rotorfoss high-speed rotary joint esuka e-Italiya, enokusebenzisa i-U-drill enesantya esiphezulu (i-drill enobundlobongela) kunye ne-core drill bit ukukhupha amanzi. qaphela ukusetyenzwa komngxuma onzulu kunye nokukhusela isixhobo ukunciphisa iindleko zokusetyenziswa.

5)Isixhobo sokuthambisa esizenzekelayo kunye nesixhobo sokukhusela:

ezifana neentsimbi zesikhokelo, izikhonkwane ezikhokelayo, ii-racks, njl., ngaphandle kweekona ezifileyo ukuqinisekisa ubomi benkonzo yesixhobo somatshini. I-X-axis kunye ne-Y-axis yesixhobo somatshini ixhotyiswe ngezixhobo zokukhusela ezinothuli, kunye nabalindi be-splash abangenamanzi bafakwe kwi-workbench.

6)Inkqubo yoLawulo lwe-CNC:

6.1 Ngomsebenzi wokuqhawula i-chip, ixesha lokuqhawula i-chip kunye nomjikelo wokuqhawula i-chip unokusetwa kwi-interface yomatshini wendoda.

6.2 Ngomsebenzi wokuphakamisa isixhobo, ukuphakama kwesixhobo kunokusetwa kwi-interface yomatshini wendoda. Xa ubhobhoza kulo mphakamo, i-drill bit iphakanyiswe ngokukhawuleza phezulu kwi-workpiece, kwaye ke i-chip iphonswa, kwaye emva koko idluliselwe ngokukhawuleza kwindawo yokugaya kwaye iguqulelwe ngokuzenzekelayo emsebenzini.

6.3Ibhokisi yolawulo lokusebenza esembindini kunye neyunithi ebanjwa ngesandla yamkele inkqubo yolawulo lwamanani, kwaye ixhotyiswe nge-USB interface kunye ne-LCD liquid crystal display. Ukuze kuququzelelwe inkqubo, ukugcinwa, umboniso kunye nonxibelelwano, ujongano lokusebenza lunemisebenzi efana nencoko yababini yomatshini, imbuyekezo yempazamo, kunye ne-alamu ezenzekelayo.

I-6.4 Umatshini unomsebenzi wokujonga kwangaphambili kunye nokuphinda uhlolisise indawo yomngxuma ngaphambi kokuba usebenze, kwaye ukusebenza kulula kakhulu.

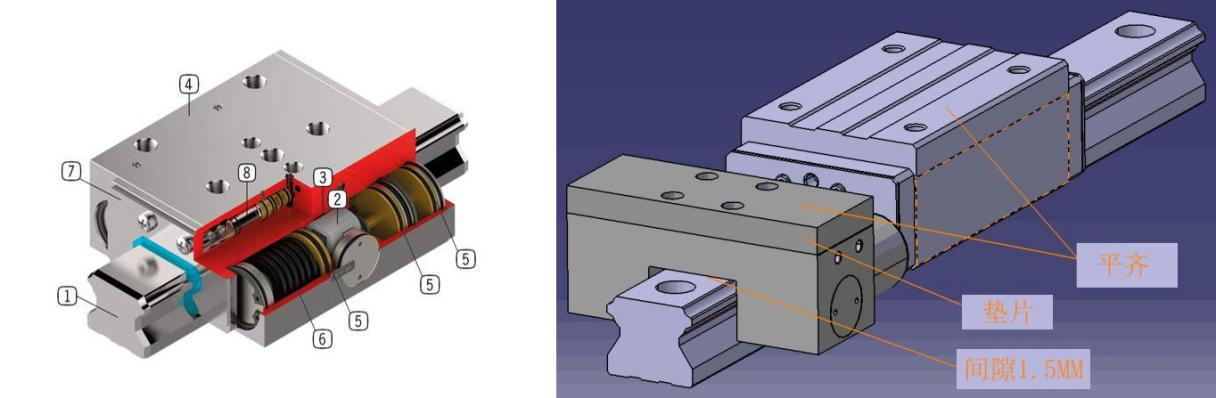

7)Isibambiso sikaloliwe

I-clamp yenziwe ngumzimba obambezelayo kunye ne-actuator. Yinto ephezulu yokusebenza kwecandelo elisetyenziswa kunye ne-rolling linear guide pair. Ivelisa amandla okuqinisa owomeleleyo ngomgaqo wokwandiswa kwebhloko emile okwe wedge. Iimpawu ezandisa ukuqina.

Iimbonakalo:

- Ikhuselekile kwaye ithembekile, inamandla okubamba awomeleleyo, ibamba i-XY axis engashukumiyo ngexesha lokomba kunye nokucofa ukucofa.

- Amandla okubamba aphezulu kakhulu, anyusa ukuqina kwe-axial feed, kwaye athintele intshukumo encinci ebangelwa kukungcangcazela.

- Ukuphendula ngokukhawuleza, ukuvula nokuvala ixesha lokuphendula yimizuzwana ye-0.06 kuphela, ekhusela isixhobo somatshini kunye nokuphucula ubomi be-screw.

- Ihlala ixesha elide, i-nickel-plated surface, i-anti-rust isebenza kakuhle.

Uyilo lwenoveli ukunqanda impembelelo engqongqo xa ubamba.

8)Isisusi setshiphu esizenzekelayo kunye nesixhobo sokupholisa esijikelezayo:

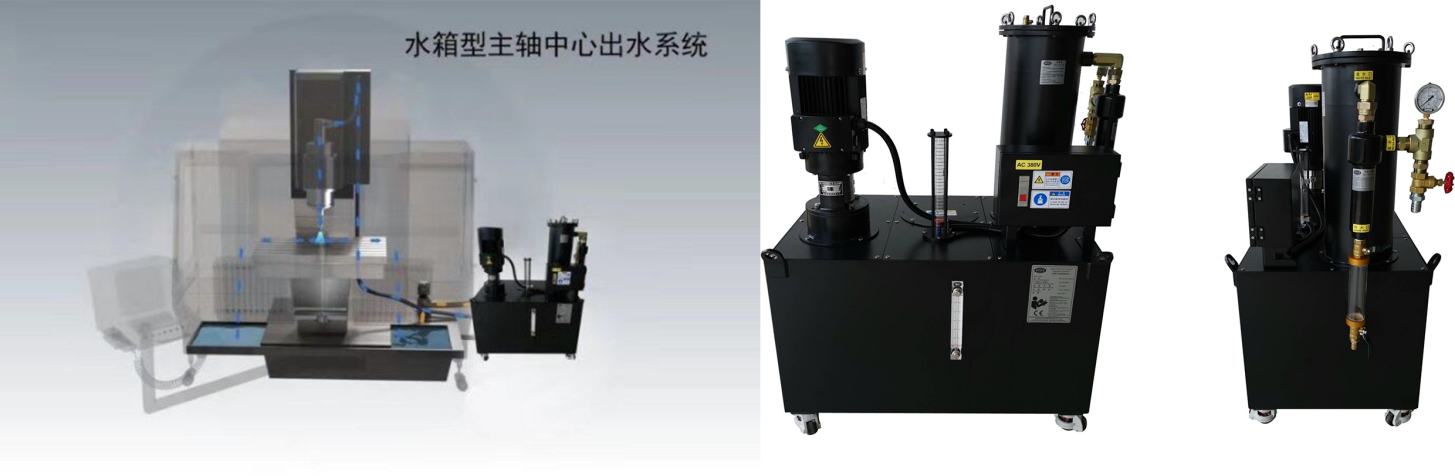

I-automatic chip remover icwangciswe ngasemva kwendawo yokusebenza kwaye icebo lokucoca licwangciswe ekugqibeleni. I-automatic chip remover luhlobo lwekhonkco elicaba, kwaye impompo yokupholisa ifakwe kwicala elinye. I-outlet ye-chip idibaniswe nenkqubo yokucoca amanzi ephakathi. Isisipholisi siphumela kwi-chip ejector. Ipompo yokuphakamisa i-chip ejector iqhubela isipholileyo kwisixokelelwano esisembindini sokuhluza amanzi. Impompo yokupholisa yoxinzelelo oluphezulu ijikeleza isipholile esihluziweyo sokusika kunye nokupholisa. Kwaye ixhotyiswe ngetroli yokuthutha itshiphu, ekulungele kakhulu ukuthutha iitshiphu zentsimbi. Esi sixhobo sixhotyiswe ngenkqubo yokupholisa yangaphakathi nangaphandle yabasiki. Xa ubhobhoza ngesantya esiphezulu, abasiki bapholiswa ngamanzi angaphakathi nangaphandle ngexesha lokugaya ukukhanya.

I-alamu yamanzi aphantsi

1) Xa isisipholisi kwisihluzi sikwinqanaba lolwelo eliphakathi, inkqubo iqhagamshela ngokuzenzekelayo imotor ukuze iqalise, kwaye isisipholisi esikwisihluzi setshiphu siqukuqelela ngokuzenzekelayo kwisihluzo. Xa inqanaba eliphezulu lolwelo lifikelelwe, injini iyayeka ukusebenza ngokuzenzekelayo.

2) Xa i-coolant kwisihluzi ikwinqanaba eliphantsi, inkqubo iya kuzisa ngokuzenzekelayo i-gauge yezinga le-liquid kwi-alamu, i-spindle iya kuhoxisa ngokuzenzekelayo isixhobo, kwaye umatshini uya kumisa umsebenzi.

9)Inkqubo yoHluzo lweNtengiso:

Lo matshini uxhotyiswe ngenkqubo yokucoca amanzi esembindini njengomgangatho, onokukuhluza ngokufanelekileyo ukungcola kwisipholisi. Inkqubo yangaphakathi yokutshiza yamanzi inokuthintela izikhonkwane zentsimbi ekubambeni isixhobo ngexesha lokucutshungulwa, ukunciphisa ukunxitywa kwesixhobo, ukwandisa ubomi besixhobo, ukuphucula umgangatho wokugqitywa komphezulu womsebenzi, Iphini lokukhupha amanzi elinoxinzelelo oluphezulu lwencam yencakuba inokukhusela kakuhle umphezulu womsebenzi, khusela i-joint-speed rotary joint, ukukhusela ukungcola ekuthinteleni i-rotary joint, kunye nokuphucula umgangatho opheleleyo we-workpiece kunye nokusebenza kakuhle.

10)Ibhola Screw kunye nesitulo esidityanisiweyo semoto:

Isiseko semoto yimveliso ephezulu yokugxila edibanisa isikrufu sebhola kunye nemoto. I-angular contact paired bear (ibakala lokuchaneka kwe-C5) idityaniswe ukuphucula ukuchaneka kunye nokuqinisekisa ukukhutshwa kwe-axial ye-zero ye-screw yebhola xa i-motor ihamba phambili kwaye ibuya umva. Ilungele ngokukodwa izixhobo eziphezulu zesantya.

Ukuchaneka kweNdibano: isikrufu sebhola kunye ne-motor zifakwe kwenye ngesiseko semoto. Nciphisa impazamo ye-concentricity ye-motor shaft kunye ne-ball screw shaft, yilawule kwi-plus okanye thabatha i-0.01mm, kwaye i-perpendicularity yobuso besiphelo yi-0.01.

11)Itheyibhile eneziphoso ezizijonge yedwa(ukhetho)

I-worktable yezixhobo zokuzijonga ixhotyiswe nge-fine-jaw hydraulic self-centing chuck. Iworkpiece inokubekwa embindini ngokuzenzekelayo kwisibambiso esinye ngaphandle kokujikeleza kwesixhobo ngasinye ukufumana iziko. I-clamping iyakhawuleza kwaye ifanelekile.

Sombulula ingxaki ukuba umsebenzi kunye indexing isangqa ngaphantsi kwe 1600 mm ububanzi ibambene ngokucinezela ipleyiti emva kokutyisa kwaye ukukhangela iziko, edla ixesha elincinci kwaye kuthatha ixesha elide clamping kunokuba processing ixesha.

I-self-centing ye-jaw chuck ephuhliswe ngokuzimeleyo kunye ne-stroke enkulu yomhlathi yenza kube nzima ukuba i-workpiece ibambe umhlathi xa ibamba. Isakhiwo se-strip kunye ne-pad sisetyenzisiweyo.Isombulula imeko yokuba i-hydraulic okanye i-pneumatic jaws inohambo oluncinane kwimarike kwaye i-workpieces enkulu iya kuchaphazela imihlathi xa iphakamisa, ibangela umonakalo kwii-chucks.

Imihlathi emine kwi-workbench ikwisitayela esiqhekezayo, kwaye ukususwa kwe-workbench yangasemva yiplatifomu eqhelekileyo kunye ne-T-groove yayo.

Specificationn

| Umzekelo | I-BOSM-DT1010 | I-BOSM-DT2010 | I-BOSM-DT2016 | I-BOSM-DT2525 | |

| Ubungakanani bokusebenza | Ubude*Ububanzi (mm) | 1000x1000 | 2000x1000 | 2000x1600 | 2500x2500 |

| Intloko yoKwemba ngokuthe nkqo | I-Spindle taper | BT40/ BT50 | BT40/ BT50 | BT40/ BT50 | BT40/ BT50 |

| Idayamitha yokomba (mm) | Φ40/Φ60 | Φ40/Φ60 | Φ40/Φ60 | Φ40/Φ60 | |

| Ukucofa idayamitha (mm) | M24 / M36 | M24 / M36 | M24 / M36 | M24 / M36 | |

| Isantya sokujikeleza (r/min) | 30-3000 | 30-3000 | 30-3000 | 30-3000 | |

| Amandla e-spindle (Kw) | 15/22 | 15/22 | 15/22 | 15/22 | |

| Umgama ukusuka ngaphantsi kwesiphelo se-spindle ukuya kumphezulu womsebenzi (mm) | 200~600 / 400~800 | 200~600 / 400~800 | 200~600 / 400~800 | 200~600 / 400~800 | |

| Phinda ukuChaneka kokuma (X/Y/Z) | X/Y/Z | ±0.01/1000mm | ±0.01/1000mm | ±0.01/1000mm | ±0.01/1000mm |

| Ubunzima obupheleleyo (T) | 8.5 | 11 | 13.5 | 16.5 | |

| Isixhobo semagazini | Imagazini yesixhobo somgca | ||||

Ukuhlolwa koMgangatho

Umatshini ngamnye we-Bosman ulinganiswe nge-laser interferometer evela kwinkampani yase-United Kingdom ye-RENISHAW, ehlola ngokuchanekileyo kwaye ihlawule iimpazamo ze-pitch, i-backlash, ukuchaneka kwendawo, kunye nokuphindaphinda ukuchaneka kokumisa ukuqinisekisa ukuguquguquka komatshini, ukuzinza kwe-static, kunye nokucubungula ukuchaneka. . Uvavanyo lwebha yebhola Umatshini ngamnye usebenzisa umvavanyi webha yebhola evela kwinkampani yaseBritani ye-RENISHAW ukulungisa ukuchaneka kwesangqa sokwenyani kunye nokuchaneka komatshini wejometri, kwaye wenze imifuniselo yokusika setyhula ngaxeshanye ukuqinisekisa ukuchaneka komatshini we-3D kunye nokuchaneka kwesangqa.

Ngaphambi nasemva kweNkonzo

1)Ngaphambi kweNkonzo

Ngokufunda isicelo kunye nolwazi oluyimfuneko kubathengi emva koko impendulo kwiinjineli zethu, iqela le-Bossman Technical lijongene nonxibelelwano lobugcisa kunye nabathengi kunye nokuqulunqwa kwezisombululo, ukuncedisa umthengi ekukhetheni isisombululo esifanelekileyo somatshini kunye noomatshini abafanelekileyo.

2)Emva kweNkonzo

A.Umatshini onewaranti yonyaka omnye kwaye uhlawulwe ulondolozo lobomi bonke.

B.Ngexesha lewaranti yonyaka omnye emva kokuba umatshini efikile kwindawo ekuyiwa kuyo, iBOSSMAN iya kubonelela ngeenkonzo zokugcinwa kwasimahla kunye nexesha elifanelekileyo kwiimpazamo ezahlukeneyo ezingenziwanga ngabantu kumatshini, kwaye zibuyisele ngexesha elifanelekileyo zonke iintlobo zomonakalo owenziwe ngumntu simahla. yentlawulo . Ukusilela okwenzeka kwixesha lewaranti kuya kulungiswa ngeentlawulo ezifanelekileyo.

Inkxaso ye-C.Technical kwiiyure ezingama-24 kwi-intanethi, i-TM, i-Skype, i-E-mail, ukusombulula imibuzo ehambelanayo ngexesha. ukuba ayinasombululo, iBOSSMAN iya kulungiselela kwangoko ukuba injineli yasemva kokuthengisa ifike kwindawo ukuze ilungiswe, umthengi ufuna ukuhlawulela iVISA, amatikiti eenqwelomoya kunye nendawo yokuhlala.

Indawo yeNkampani