Uhlobo lweGantry CNC Ukomba kunye noMatshini wokugaya

I-CNC Gantry Milling kunye noMashini wokuBomba

Gantry Drilling kunye Milling Machine

CNC Gantry Milling Machine

Ukusetyenziswa komatshini

IBOSM gantry mobile CNC high-speed drilling and milling machine series zisetyenziswa ikakhulu ekugrunjweni okuphezulu kunye nokulungiswa kwamacwecwe amakhulu, iiflange zamandla omoya, iidiski, iinxalenye zeringi kunye nezinye izixhobo zokusebenza ezinobunzima ngaphakathi koluhlu olusebenzayo. Ukugrumba imingxunya kunye nemingxuma engaboniyo kunokubonwa kumacandelo esixhobo esinye kunye nezixhobo ezidibeneyo. Inkqubo yomatshini wesixhobo somatshini ilawulwa ngedijithali, kwaye ukusebenza kulula kakhulu. Iyakwazi ukuqonda i-automation, ukuchaneka okuphezulu, iindidi ezininzi kunye nemveliso yobuninzi. Ukuze kuhlangatyezwane neemfuno zokusetyenzwa kwabasebenzisi abahlukeneyo, inkampani iye yavelisa iintlobo ngeentlobo zeemveliso ezigqityiweyo. Ukongeza kwiimodeli eziqhelekileyo, zinokuthi ziyilwe kwaye zenziwe ngokweemfuno zabasebenzisi.

Ulwakhiwo lomatshini

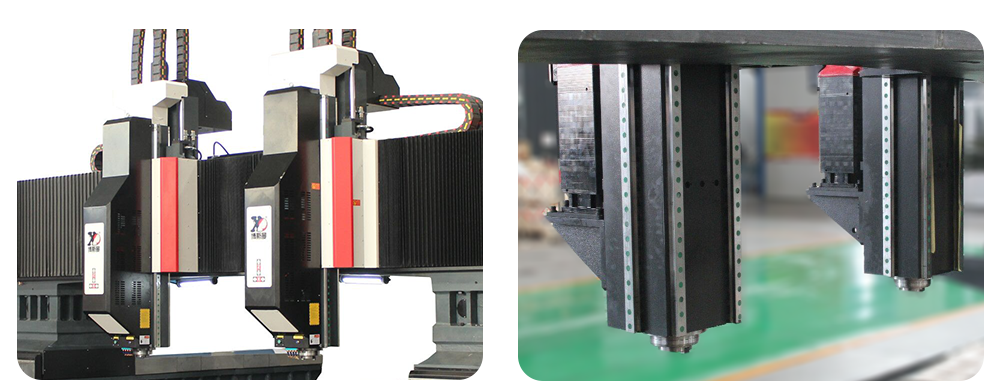

Esi sixhobo ikakhulu iqulathe ibhedi worktable, gantry ezihambayo, ukutyibilika isali, ukubhola kunye nentloko amandla okugaya, isixhobo sokuthambisa oluzenzekelayo kunye nesixhobo sokukhusela, isixhobo sokupholisa esijikelezayo, inkqubo yolawulo lwedijithali, inkqubo yombane, njl. njl. i-lead screw pair drive, isixhobo somatshini sinokuchaneka kokubeka okuphezulu kunye nokuphinda ukuchaneka kokubeka.

1)Itafile yokusebenza:

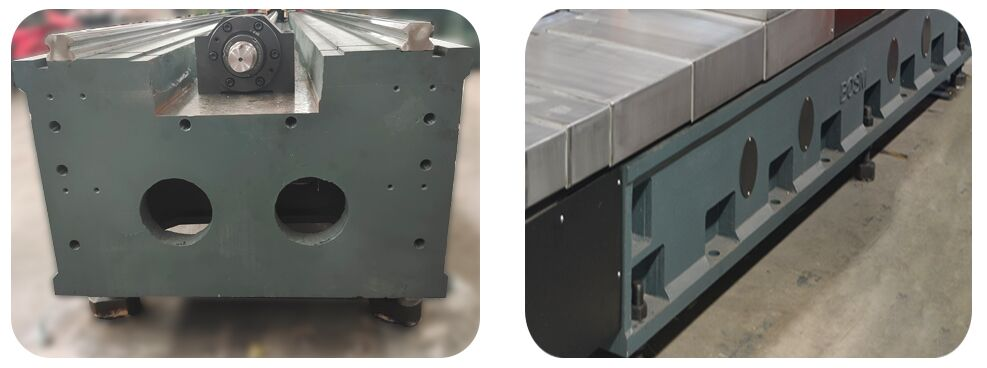

Ibhedi sisiqwenga esinye sokuphonswa, esigqityiweyo emva kokuthotywa kwesibini kunye nonyango lokuguga lokungcangcazela, ngokuqina okuguquguqukayo kunye nokuzinzileyo kwaye akukho deformation. Kukho i-T-slots kunye noyilo olufanelekileyo lokugqiba kumphezulu wetafile esebenzayo ukwenzela ukubamba i-workpieces. Isiseko sebhedi sixhotyiswe nge-2 izikhokelo ze-linear ezichanekileyo (4 kumacala omabini ngokubanzi), ukwenzela ukuba i-slider yesikhokelo igxininiswe ngokulinganayo, ephucula kakhulu ukuqina kwesixhobo somatshini kunye nokuxhatshazwa kwayo kunye nokunyanzeliswa koxinzelelo. Inkqubo yokuqhuba ithatha iimotor ze-AC servo kunye ne-precision ball screw pairs. I-side drive yenza i-gantry ihambe kwicala le-X-axis. Iibholiti ezilungelelaniswayo zisasazwa kumphezulu ophantsi webhedi, onokuthi ulungelelanise ngokulula inqanaba le-worktable yebhedi.

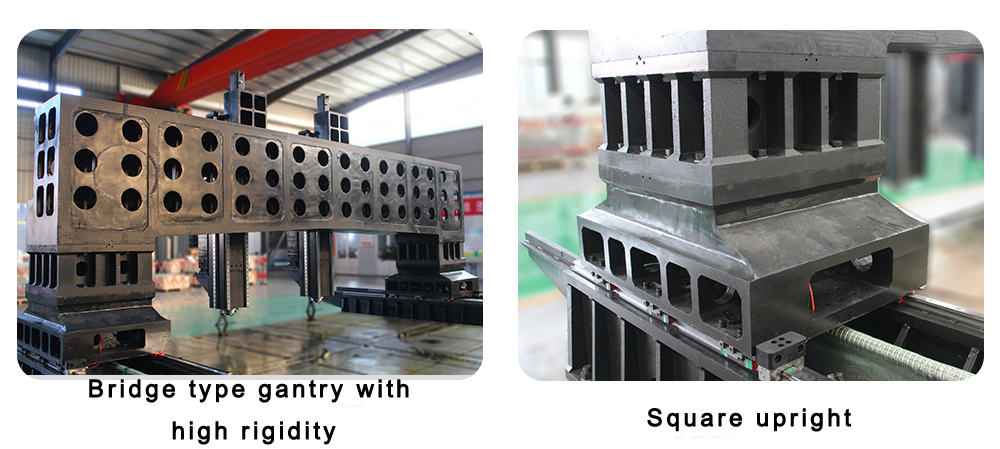

2)Movinggantry:

I-gantry ehambayo iphoswe kwaye iqhutywe ngentsimbi engwevu (HT250). Ezimbini 55# ultra-high ezithwele umthamo ukuqengqeleka izibini isikhokelo linear zifakwe kwicala langaphambili gantry. Iseti ye-precision ibhola screw pair kunye ne-servo motor yenza isilayidi sentloko yamandla ukuba sihambe kwicala le-Y-axis, kunye nentloko yamandla okugaya ifakwe kwi-slide yentloko yamandla. Intshukumo ye-gantry ibonwa ngokujikeleza kwebhola jijwa nut kwi-screw yebhola eqhutywa yi-servo motor ngokudibanisa okuchanekileyo.

3)Movingisali yokutyibilika:

Isali yokutyibilika yintsimbi echanekileyo. Isali yokutyibilika ixhotyiswe ngezilayidi zikaloliwe ezimbini eziphezulu ezithwele umthwalo ophakamileyo we-CNC, iseti yezibini ezichanekileyo zebhola kunye nokunciphisa okuphezulu kweplanethi echanekileyo edityaniswe kwi-servo motor, kwaye ixhotyiswe nge-nitrogen Balance cylinder, ukulinganisela ubunzima Intloko yamandla, ukunciphisa umthwalo wesikrufu sokukhokela, ukwandisa ubomi besikrufu sokukhokela, qhuba intloko yamandla okomba ukuba uhambe kwicala le-Z-axis, kwaye uqaphele ukukhawuleza ukuya phambili, ukusebenzela phambili, umva ngokukhawuleza, kunye nokuyeka izenzo ze-axis. intloko yamandla, kunye nokuqhawuka kweChip ngokuzenzekelayo, ukususwa kwetshiphu, umsebenzi wokumisa.

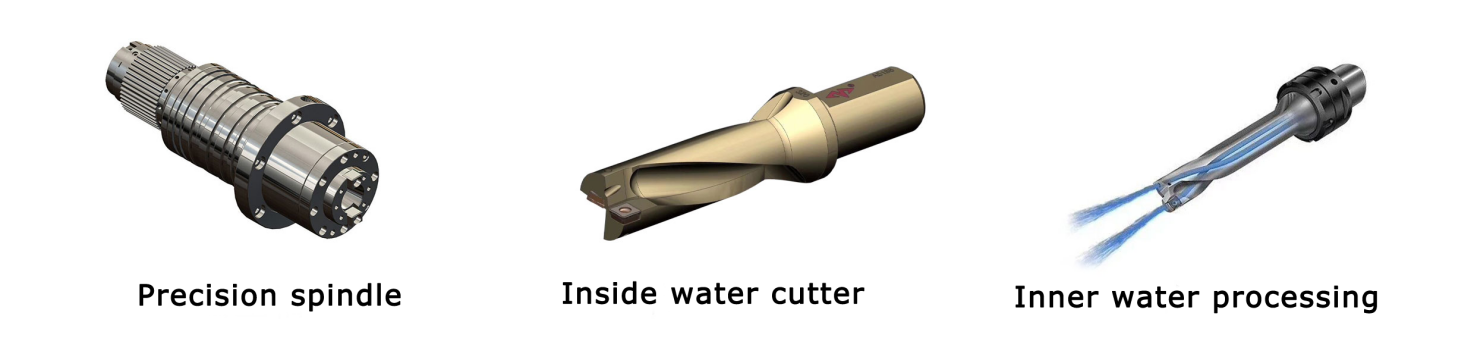

4)Drilling intloko amandla(Spindle):

Intloko yamandla okomba ithatha i-servo spindle motor, eqhutywa yi-toothed synchronous belt deceleration ukunyusa i-torque kwaye iqhube i-spindle echanekileyo ezinikeleyo. Umjikelo wamkela ezine zokuqala kunye nemiqolo emibini engasemva emithandathu yeebheringi zoqhagamshelwano ze-angular yaseJapan ukufikelela kwisantya esingenanyathelo. I-spindle ixhotywe ngesixhobo sokutshintsha isixhobo somoya ukwenza isixhobo Ukutshintshwa ngokukhawuleza kwaye kulula, kwaye isondlo siqhutywa yi-servo motor kunye ne-screw yebhola. I-X kunye ne-Y axes zinokudityaniswa, zisebenzisa i-semi-closed loop control, enokuqonda imisebenzi yokudibanisa kunye nesetyhula. Isiphelo se-spindle yi-BT50 ye-taper hole, exhotyiswe nge-Italian Rotofors edibeneyo ejikelezayo ejikelezayo, enokuthi iqhutywe yi-U-drilling center ephezulu.

4.1 Umzimba webhokisi kunye netheyibhile yokutyibilika yentloko yamandla okomba yenziwe ngeecastings ukuqinisa ukuqina kunye nokuzinza, kunye nokunciphisa ukungcangcazela kunye nengxolo.

4.2 Isixhobo somatshini sinokusebenza ngevili lesandla sombane; ukuze ugcine ixesha kunye nokuphucula ukusebenza kakuhle kwemveliso ngexesha lokucubungula, emva kokugrumba umngxuma wokuqala ukuseta indawo yokutya, ukugrumba imingxunya eseleyo yohlobo olufanayo kunokufikelela ngokukhawuleza phambili → umsebenzi kwangaphambili → umva okhawulezayo Kufuneka kwakhona ibe nemisebenzi efana netshiphu ezenzekelayo. ukwaphuka, ukususwa kwetshiphu, kunye nokunqumama.

4.3 Inkunzi yegusha ixhotyiswe nge-liquid nitrogen balance system yokunciphisa umthwalo we-Z-axis kunye nokwandisa ubomi benkonzo ye-screw ye-Z-axis.

4.4 I-Z-axis servo motor ithatha i-power-off brake motor, eya kubamba i-brake xa umbane unqunyulwa ngokukhawuleza ukuphepha iingozi ezibangelwa ukuwa kwebhokisi lokuphotha.

4.5 Intloko

4.5.1. Ibhokisi ye-shaft ephambili ithatha izikhokelo ezine zomgca onzima, ezinobungqongqo obuphezulu bentshukumo, ukuchaneka kwendawo ephezulu, kunye nokuzinza okuhle kwesantya esisezantsi.

4.5.2. I-Z-axis drive-i-servo motor iqhagamshelwe ngokuthe ngqo kwi-screw yebhola kwi-coupling, kwaye isikrufu sebhola siqhubela isitokhwe sentloko ukuba siye phezulu sisehla kwisali ukuze siqonde i-Z-axis feed. Injini ye-Z-axis inomsebenzi wokuqhawuka oluzenzekelayo. Xa kwenzeka ukusilela kwamandla, i-motor shaft ibanjwe ngokuqinileyo ukukhusela ukuba ingajikelezi.

4.5.3. Iqela le-spindle lamkela i-Taiwan Jianchun ye-spindle yangaphakathi ye-speed yangaphakathi yokuphuma kwamanzi, enokuchaneka okuphezulu kunye nokusebenza okuphezulu. I-shaft engundoqo ibamba imela nge-butterfly spring kwi-shaft engundoqo kunye ne-tension force esebenza kwisikhonkwane sokutsalwa kwesixhobo sokwenza isixhobo ngokusebenzisa indlela ye-broach eneenxalenye ezine, kwaye isixhobo esikhululekile samkela indlela ye-pneumatic.

5)Isixhobo sokuthambisa esizenzekelayo kunye nesixhobo sokukhusela:

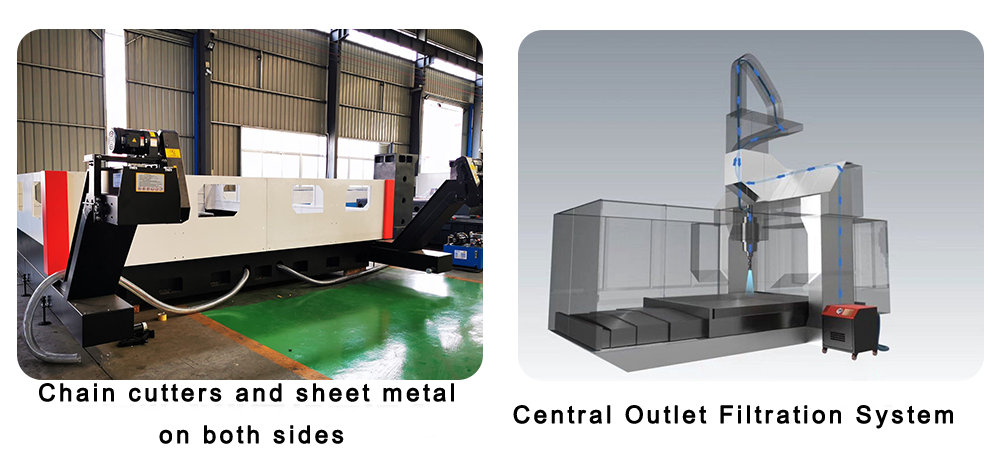

Kukho ukuhanjiswa kwetshiphu okuzenzekelayo kumacala omabini ebhentshi yokusebenza kunye nesihluzi ekupheleni. I-automatic chip conveyor luhlobo olusicaba. Elinye icala lixhotyiswe ngempompo yokupholisa, kwaye i-outlet ixhunywe kwinkqubo yokucoca amanzi ephakathi kunye ne-hose. , Isisipholisi siphumela kwisidluliseli setshiphu, impompo yokunyusa itshiphu impompa isipholileyo kwisixokelelwano sesihluzo esisembindini, kwaye impompo yokupholisa yoxinzelelo oluphezulu ijikelezisa isizipholisi esihluziweyo ukuya kupholisa ukusongelwa kokusonta. Ikwaxhotyiswe ngetroli yokuthutha itshiphu, ekulungele kakhulu ukuthutha iitshiphusi. Esi sixhobo sixhotyiswe ngeenkqubo zokupholisa izixhobo zangaphakathi nangaphandle. Xa kusetyenziswa i-speed-speed drilling, ukupholisa kwangaphakathi kwesixhobo kusetyenziswa, kwaye ukupholisa kwangaphandle kusetyenziselwa ukugaya ukukhanya.

5.1. Inkqubo yokucoca amanzi kwindawo esembindini:

Esi sixhobo somatshini sixhotyiswe ngenkqubo yokucoca amanzi esembindini, enokucoca ngokufanelekileyo ukungcola kwisipholisi. Inkqubo yangaphakathi yokutshiza amanzi inokuthintela izikhonkwane zentsimbi ukuba zingabotshelelwa kwisixhobo ngexesha lokucutshungulwa, ukunciphisa ukunxiba kwesixhobo, ukwandisa ubomi besixhobo, kunye nokuphucula ukugqitywa komphezulu womsebenzi. Isixhobo sokukhupha isikhonkwane sokukhupha amanzi esinoxinzelelo oluphezulu sinokukhusela kakuhle umphezulu we-workpiece, ukukhusela i-joint rotary enesantya esiphezulu, ukuthintela ukungcola ekuthinteleni i-rotary joint, kunye nokuphucula umgangatho we-workpiece yonke, kunye nokuphucula ukusebenza kakuhle.

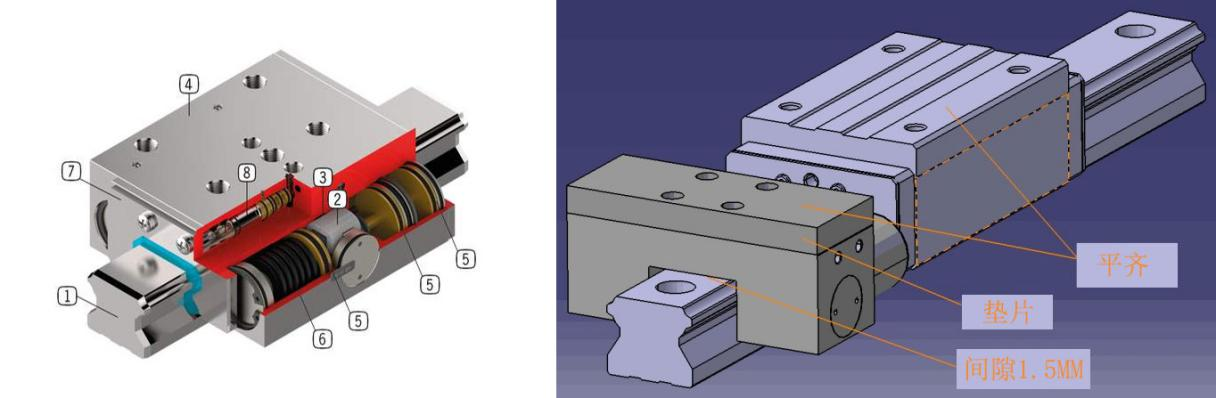

6)Linear Clamper:

I-clamp yenziwe ngumzimba oyintloko we-clamp, i-actuator, njl. Ngomgaqo-siseko wokwandiswa kwe-wedge block force, ivelisa amandla anamandla okubamba; ine-gantry esisigxina, indawo echanekileyo, i-anti-vibration kunye noMsebenzi wokuphucula ukuqina.

Inezi mpawu zilandelayo:

Ikhuselekile kwaye ithembekile, amandla okubamba awomeleleyo, abambe i-axis ye-XY engashukumiyo ngexesha lokomba kunye nokucofa ukucofa.

Amandla okubamba aphezulu kakhulu anyusa ukuqina kokutya kwe-axial kwaye anqande ukuphazamiseka okubangelwa kukungcangcazela.

Ukuphendula ngokukhawuleza, ixesha lokuphendula lokuvula kunye nokuvala yimizuzwana ye-0.06 kuphela, enokukhusela isixhobo somatshini kunye nokwandisa ubomi be-screw lead.

Ihlala ixesha elide, i-nickel-plated surface, i-anti-rust isebenza kakuhle.

Uyilo lwenoveli ukunqanda impembelelo engqongqo xa uqiniswa.

7)Ukuma kunye nokubambelela kwi-workpiece

Ukulungelelaniswa kweflange engqukuva, inokubekwa ngokungenasizathu kwipleyiti yenkxaso ene-T-slots, kwaye indawo esembindini ilinganiswa ne-edge finder efakwe kumngxunya we-spindle taper kuzo naziphi na iingongoma ezintathu (i-diameter yangaphakathi okanye i-diameter yangaphandle) kwi-workpiece. . Emva koko, ifunyenwe ngokuzenzekelayo ngokubala inkqubo yokulawula amanani, echanekileyo kwaye ikhawuleza. I-clamping ye-workpiece igxininiswe yi-clamp eyenziwe ngeplate yokucinezela, intonga ye-ejector, intonga yokubopha kunye ne-cushion block, ekulungele ukuyisebenzisa.

8)Isixhobo sokuthambisa esizenzekelayo

Esi sixhobo somatshini sixhotyiswe ngesixhobo sokuthambisa esizenzekelayo se-volumetric saseTaiwan, esinokuthambisa ngokuzenzekelayo izibini ezishukumayo ezinje ngeereyili zesikhokelo, izikrufu ezikhokelayo, iirakhi, njl., ngaphandle kweziphelo ezifileyo, kwaye ziqinisekise ubomi benkonzo yesixhobo somatshini. Iireyili zesikhokelo kumacala omabini ombhede womatshini zixhotyiswe ngeentsimbi zokukhusela ezikhuselekileyo, kwaye macala omabini entloko yamandla e-gantry ehambayo axhotyiswe ngezixhobo ezikhuselayo eziguquguqukayo. Iigada zokutshiza zamanzi zifakwe malunga netafile yokusebenza, kwaye umgca wombhobho wamanzi ukhuselwe ngetsheyini yokutsala yeplastiki. Kufakwe umkhusane othambileyo ocacileyo wePVC ojikeleze umjikelo.

9)Isilawuli esipheleleyo sedijithali se-CNC:

9.1. Ngomsebenzi wokuqhekeka kwetshiphu, ixesha lokuqhekeka kwetshiphu kunye nomjikelo wokuqhekeka kwetshiphu unokusetwa kujongano lomatshini womntu.

9.2. Ngomsebenzi wokuphakamisa isixhobo, ukuphakama kwesixhobo kunokusetwa kwi-interface yomatshini wendoda. Xa ubhobhoza kulo mphakamo, i-drill bit iphakanyiselwa ngokukhawuleza phezulu kwi-workpiece, kwaye emva koko i-shavings, emva koko ikhawuleze ukuya kwindawo yokugaya kwaye iguqulelwe ngokuzenzekelayo kwisondlo somsebenzi.

9.3. Ibhokisi yolawulo lokusebenza esembindini kunye neyunithi ephathwayo ithatha inkqubo yolawulo lwamanani, kwaye ixhotyiswe ngojongano lwe-USB kunye nomboniso wecrystal engamanzi weLCD. Ukuze kuququzelelwe inkqubo, ukugcinwa, umboniso kunye nonxibelelwano, ujongano lokusebenza lunemisebenzi efana nencoko yababini yomatshini, imbuyekezo yempazamo, kunye ne-alamu ezenzekelayo.

9.4. Isixhobo sinomsebenzi wokujonga kwangaphambili kunye nokuhlolwa kwakhona kwendawo yokubeka umngxuma phambi kokucubungula, okulungele kakhulu ukusebenza.

10)Umkhangeli we-Optical edge:

Izixhobo zixhotyiswe nge-photoelectric edge finder, enokuthi ifumane indawo yomsebenzi ngokufanelekileyo kwaye ngokukhawuleza.

1) Faka i-edge finder kwi-spindle chuck yesixhobo somatshini, kwaye ujikelezise kancinci i-spindle ukulungisa ubunzulu bayo.

I-2) Hambisa i-spindle nge-handwheel, ukwenzela ukuba umgca webhola lensimbi ye-edge finder uthinte i-workpiece encinci, kwaye ukukhanya okubomvu kuvuliwe. Ngeli xesha, i-spindle inokuhanjiswa phambili kwaye ngasemva ngokuphindaphindiweyo ukuze ifumane eyona ndawo ingcono apho umgca webhola yentsimbi ye-edge finder ithinta i-workpiece. .

3) Rekhoda amaxabiso e-X kunye ne-Y axis aboniswe yinkqubo ye-CNC ngeli xesha, kwaye ugcwalise ikhompyutha.

4) Fumana amanqaku amaninzi okufumanisa ngale ndlela

11)I-alam yokunxiba isixhobo

I-alam yokunxiba isixhobo ibona ubukhulu becala ikhoyo ngoku yemoto yokuphotha. Xa i-current idlula ixabiso lokusetha kwangaphambili, isixhobo sigweba ngokuzenzekelayo ukuba isixhobo siphelile, kwaye i-spindle iya kuhoxisa ngokuzenzekelayo isixhobo ngeli xesha, kwaye inkqubo ezenzekelayo iya kugqiba. Khumbuza umsebenzisi ukuba isixhobo siphelile.

12)I-alamu yomgangatho wamanzi aphantsi

1) Xa isisipholisi kwisihluzi sikwinqanaba eliphakathi, inkqubo iqhagamshela ngokuzenzekelayo kwinjini ukuze iqalise, kwaye isisipholisi esikwisihambisi setshiphu siqukuqelela ngokuzenzekelayo kwisihluzo. Xa ifika kwinqanaba eliphezulu, injini iyayeka ukusebenza ngokuzenzekelayo.

2) Xa i-coolant kwi-filter ikwinqanaba eliphantsi, inkqubo iya kwenza ngokuzenzekelayo i-gauge yezinga kwi-alamu, i-spindle iya kuhoxisa ngokuzenzekelayo isixhobo, kwaye umatshini uya kuyeka ukusebenza.

I-13) Umsebenzi wememori yokucima amandla

Ngenxa yokuyeka ukusebenza okubangelwa kukungaphumeleli kombane ngesiquphe, lo msebenzi unokukhawuleza kwaye ufumane indawo yomngxuma wokugqibela ogrunjiweyo phambi kokusilela kombane. Abaqhubi banokuqhubeka ngokukhawuleza kwinyathelo elilandelayo, begcina ixesha lokukhangela.

Ukuhlolwa kwelaser ene-axis ezintathu:

Umatshini ngamnye we-Bosman ulinganiswe kunye ne-laser interferometer yenkampani yaseBritane i-RENISHAW, kwaye ihlola ngokuchanekileyo kwaye ihlawule impazamo ye-pitch, i-backlash, ukuchaneka kwendawo, ukuphindaphinda ukuchaneka kokumisa, njl., Ukuqinisekisa ukuguquguquka, ukuzinza kunye nokuchaneka komatshini . Ukuhlolwa kwe-Ballbar Umatshini ngamnye usebenzisa ibha yebhola yenkampani ye-RENISHAW yaseBritani ukulinganisa ubunyani besangqa kunye nokuchaneka komatshini wejometri. Kwangaxeshanye, umfuniselo wokusika ojikelezayo wenziwa ukuqinisekisa ukuchaneka komatshini we-3D kunye nokuchaneka kwesangqa.

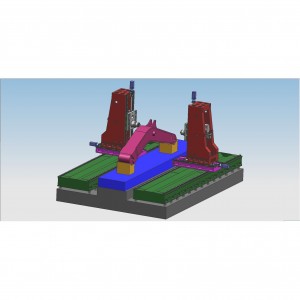

Iplatform layout, workpiece clamping, iimfuno ukususwa chip oluzenzekelayo

1. Iqonga eliphambili (i-1 iipcs): I-T-slot clamping workpiece. Zombini umphezulu wesiphelo esiphezulu kunye nomgangatho osecaleni weqonga eliphambili linokusetyenziswa njengeendawo zokubeka indawo.

2. Iqonga lokucwila (i-1 ii-pcs): (icala lixhotyiswe ngesakhelo esincedisayo sokucofa, kwaye phezulu ixhotyiswe ngekhava yokukhusela egcweleyo, eyilwe kwaye ifakwe ngumthengisi), i-workpiece ephambili yokubeka kunye nemiyalelo yokucubungula:

Ukusetyenzwa kwe-Valve cover: ukubekwa kweqonga elisezantsi (i-handle yenkxaso esezantsi kunye ne-workpieces yobukhulu obuhlukeneyo), ipleyiti yoxinzelelo ephezulu igxininiswe ngokucinezela okanye umthengisi uyila isixhobo esizenzekelayo sokudibanisa phezulu.

Ukucutshungulwa komzimba weValve: ukubekwa kweqonga elisezantsi (izibambo zenkxaso esezantsi kunye nezixhobo zokusebenza ezinobukhulu obahlukeneyo), izibambo zecala zekholamu encedisayo yeqonga elisezantsi kunye ne-L-shaped accessory ejector rods zicinezelwe kwaye zigxininiswe okanye umthengisi uyila umphezulu ozenzekelayo. isixhobo sokubamba.

Inkcazo

| Umzekelo | I-BOSM-DS3030 | I-BOSM-DS4040 | I-BOSM-DS5050 | I-BOSM-DS6060 | |

| Ubungakanani bokusebenza | ubude*ububanzi | 3000*3000 | 4000*4000 | 5000*5000 | 6000*6000 |

| Intloko yoKwemba ngokuthe nkqo | I-Spindle taper | BT50 | |||

| Idayamitha yokuBomba (mm) | φ96 | ||||

| Ukucofa iDiameter(mm) | M36 | ||||

| Isantya seSpindle (r/min) | 30~3000/60~6000 | ||||

| Spindle Motor Power (kw) | 22/30/37 | ||||

| Impumlo yokuphotha ukuya kwitheyibhile Umgama | Ngokutsho kwesiseko | ||||

| Phinda ukuChaneka kokuma (X/Y/Z) | X/Y/Z | ±0.01/1000mm | |||

| Inkqubo yokulawula | KND/GSK/SIEMENS | ||||

| Isixhobo seMagazini | Isixhobo semagazini ye-Okada esinezixhobo ezingama-24 njengokuzikhethela | ||||

Ukuhlolwa koMgangatho

Umatshini ngamnye we-Bosman ulinganiswe nge-laser interferometer evela kwinkampani yase-United Kingdom ye-RENISHAW, ehlola ngokuchanekileyo kwaye ihlawule iimpazamo ze-pitch, i-backlash, ukuchaneka kwendawo, kunye nokuphindaphinda ukuchaneka kokumisa ukuqinisekisa ukuguquguquka komatshini, ukuzinza kwe-static, kunye nokucubungula ukuchaneka. . Uvavanyo lwebha yebhola Umatshini ngamnye usebenzisa umvavanyi webha yebhola evela kwinkampani yaseBritani ye-RENISHAW ukulungisa ukuchaneka kwesangqa sokwenyani kunye nokuchaneka komatshini wejometri, kwaye wenze imifuniselo yokusika setyhula ngaxeshanye ukuqinisekisa ukuchaneka komatshini we-3D kunye nokuchaneka kwesangqa.

Indawo yokusetyenziswa kwesixhobo somatshini

1.1 Izixhobo zokusingqongileyo iimfuno

Ukugcina iqondo elingaguqukiyo lobushushu be-ambient yinto eyimfuneko kumatshini ochanekileyo.

(1) Ubushushu obukhoyo be-ambient yi -10 ℃ ~ 35 ℃. Xa ubushushu be-ambient bungama-20 ℃, ukufuma kufuneka kube yi-40 ~ 75%.

(2) Ukuze kugcinwe ukuchaneka okumileyo kwesixhobo somatshini ngaphakathi koluhlu oluchaziweyo, elona qondo lobushushu lendawo lifuneka ukuba libe yi-15 ° C ukuya kuma-25 ° C kunye nomahluko wobushushu.

Akufunekanga idlule ± 2 ℃ / 24h.

1.2 Amandla ombane ombane: isigaba se-3, i-380V, ukuguquguquka kombane ngaphakathi kwe-± 10%, i-frequency supply frequency: 50HZ.

1.3 Ukuba i-voltage kwindawo yokusetyenziswa ayizinzile, isixhobo somatshini kufuneka sixhotyiswe umbane olawulwayo ukuze kuqinisekiswe ukusebenza okuqhelekileyo kwesixhobo somatshini.

1.4. Isixhobo somatshini kufuneka sibe nesiseko esithembekileyo: ucingo lokumisa lucingo lobhedu, ububanzi bocingo akufunekanga lube ngaphantsi kwe-10mm², kwaye ukuxhathisa komhlaba kungaphantsi kwe-4 ohms.

1.5 Ukuze kuqinisekiswe ukusebenza okuqhelekileyo kwesixhobo, ukuba umoya ocinezelweyo womthombo womoya uyasilela ukuhlangabezana neemfuno zomthombo womoya, iseti yezixhobo zokucoca umthombo womoya (i-dehumidification, degreasing, filtering) kufuneka yongezwe phambi kokuba umoya wokungena kumatshini.

1.6. Izixhobo kufuneka zigcinwe kude nelanga elithe ngqo, ukungcangcazela kunye nemithombo yokushisa, kwaye kude neejeneretha eziphezulu ze-frequency, oomatshini be-welding yombane, njl., ukwenzela ukuba ugweme ukusilela kokuvelisa umatshini okanye ukulahleka kokuchaneka komatshini.

Ngaphambi nasemva kweNkonzo

1)Ngaphambi kweNkonzo

Ngokufunda isicelo kunye nolwazi oluyimfuneko kubathengi emva koko impendulo kwiinjineli zethu, iqela le-Bossman Technical lijongene nonxibelelwano lobugcisa kunye nabathengi kunye nokuqulunqwa kwezisombululo, ukuncedisa umthengi ekukhetheni isisombululo esifanelekileyo somatshini kunye noomatshini abafanelekileyo.

2)Emva kweNkonzo

A.Umatshini onewaranti yonyaka omnye kwaye uhlawulwe ulondolozo lobomi bonke.

B.Ngexesha lewaranti yonyaka omnye emva kokuba umatshini efikile kwindawo ekuyiwa kuyo, iBOSSMAN iya kubonelela ngeenkonzo zokugcinwa kwasimahla kunye nexesha elifanelekileyo kwiimpazamo ezahlukeneyo ezingenziwanga ngabantu kumatshini, kwaye zibuyisele ngexesha elifanelekileyo zonke iintlobo zomonakalo owenziwe ngumntu simahla. yentlawulo . Ukusilela okwenzeka kwixesha lewaranti kuya kulungiswa ngeentlawulo ezifanelekileyo.

Inkxaso ye-C.Technical kwiiyure ezingama-24 kwi-intanethi, i-TM, i-Skype, i-E-mail, ukusombulula imibuzo ehambelanayo ngexesha. ukuba ayinasombululo, iBOSSMAN iya kulungiselela kwangoko ukuba injineli yasemva kokuthengisa ifike kwindawo ukuze ilungiswe, umthengi ufuna ukuhlawulela iVISA, amatikiti eenqwelomoya kunye nendawo yokuhlala.

Isiza soMthengi