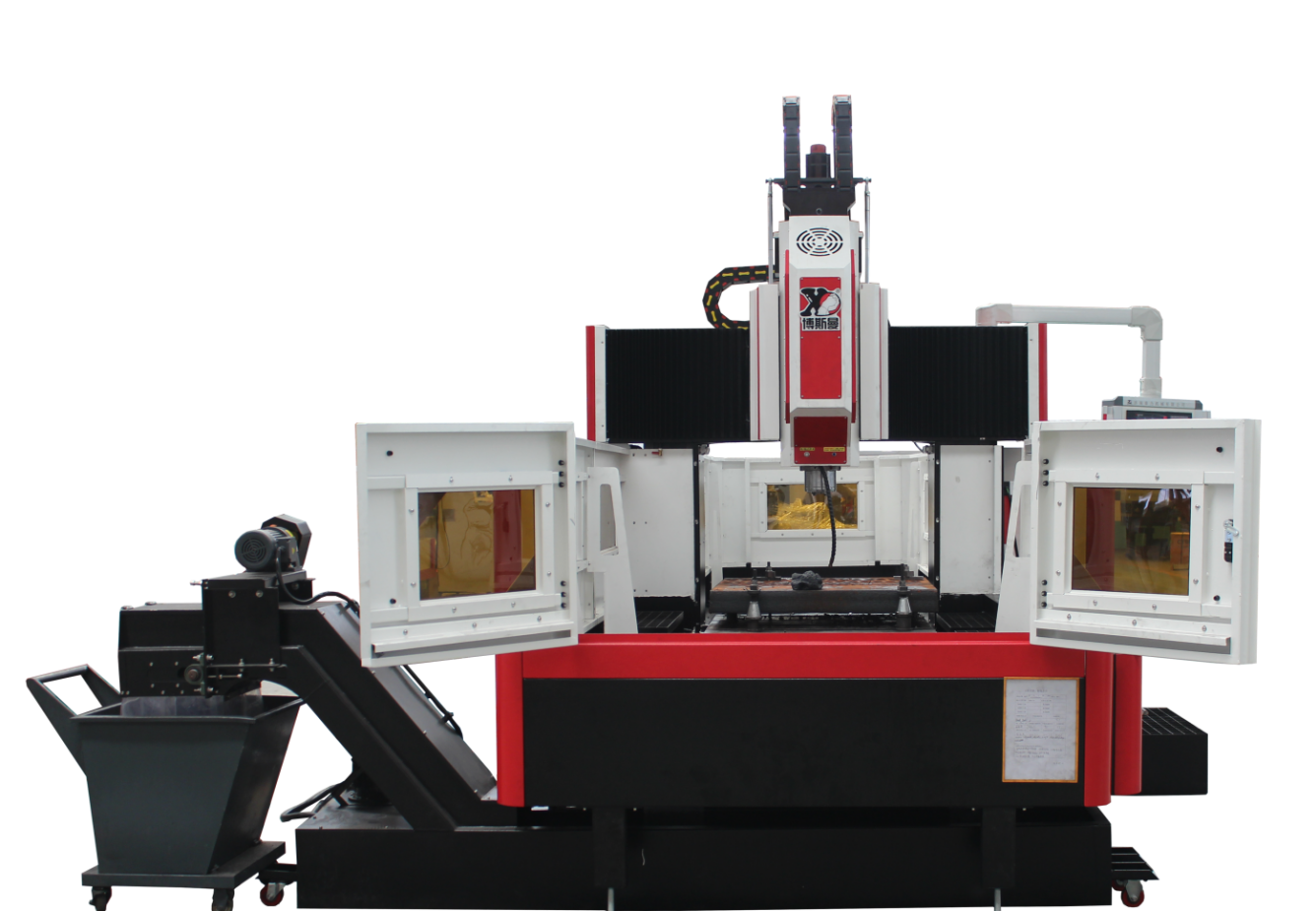

I-Fixed Beam CNC Drilling kunye noMatshini wokugaya

CNC Drilling kunye Milling Machine

Umsebenzi womatshini kunye neNkcazelo yoMsebenzi

I-1) I-CNC gantry drilling kunye nomatshini wokugaya sisixhobo somatshini esidibanisa itekhnoloji ephezulu efana noomatshini, umbane, kunye ne-hydraulics. Isetyenziselwa ikakhulu ukucubungula ukungunda, iiflanges, iivalvu, iinxalenye zesakhiwo ect. Isetyenziswa kakhulu ekurhangqweni nasekugqityweni kwamalungu antsonkothileyo afana neepleyiti ezahlukeneyo, iibhokisi, iifreyimu, ukungunda njalo njalo kushishino lokwenziwa koomatshini. Esi sixhobo somatshini sinokuqonda i-horizontal (Y-axis) kunye nentshukumo ethe nkqo (i-Z-axis) yentloko yokusila ethe nkqo kunye netheyibhile I-Three-axis yokudibanisa i-longitudinal movement (X axis). Ukusetyenzwa kweenkqubo ezininzi ezifana nokusila, ukukruqula, ukugrumba, ukucofa okuqinileyo, ukubuyisela kwakhona, kunye nokucwiliswa kwezinto zokubala kunokwenziwa. Umatshini wonke uthatha isakhiwo sesakhelo se-gantry, enokuqina okuphezulu kunye nokugcinwa kokuchaneka okulungileyo. Lukhetho lokuqala kubasebenzisi ukuba baqhubeke.

2) Uyilo olupheleleyo lomatshini

(1) I-beam esisigxina yohlobo lwesakhiwo se-gantry esamkelweyo, ibhedi igxininiswe, kunye nekholamu ephindwe kabini kunye nebhedi idibaniswe ngeebholiti. I-worktable ihamba kwi-axis ye-X ebhedini, i-headstock ihamba ngendlela ye-Z kwi-sali, kunye ne-saddle kunye ne-headstock ihamba ngendlela ye-Y kwi-beam.

2 Ezi nxalenye zikhulu zilungiswa ngesoftware yekhompyuter ye-3D, kunye noyilo olufanelekileyo lweembambo kunye neenkqubo ezipheleleyo zonyango lobushushu ukuphelisa uxinzelelo olushiyekileyo. , Ukuqinisekisa ukuba umatshini wonke unamandla okwaneleyo, ukuqina kunye nokuzinza okuphezulu, ukusika ukuxhatshazwa kwe-vibration.

3 )Ibhedi-Yokusebenzela

(1) Ibhedi yenziwe ngentsimbi ephezulu yokuqina kweHT250, kusetyenziswa uyilo lwekhompyuter olunamacala amathathu, iimbambo zicwangciswe ngokufanelekileyo, kwaye ukuqina kunye nokomelela kwayo kuphuculwe.

(2) Isikhokhelo se-X-axis samkela izikhokelo zemigca enzima evela kumazwe angaphandle, ene-coefficient esezantsi eguquguqukayo kunye ne-static yefriction, ubuntununtunu betafile ephezulu, isantya esisezantsi sokungcangcazela, isantya esisezantsi sokukhasa, ukuchaneka kwendawo ephezulu, kunye nokusebenza okugqwesileyo kwe-servo drive. : ngelo xesha, umthamo womthwalo mkhulu, kwaye ukuxhathisa ukusika kwe-vibration kulungile. .

3 Ukuqina.

4 ) Umtha

(1) I-crossbeam kunye nekholomu idibaniswe kwisakhiwo sefreyimu ye-gantry, isebenzisa i-HT250 ephezulu yentsimbi, iimbambo zicwangciswe ngokufanelekileyo, kwaye zineengqinisiso ezaneleyo zokugoba kunye nokuqina kwe-torsion.

(2) Isibini sesikhokelo se-beam samkela isikhokelo esinzima somgca.

3

5)Intloko

(1) I-headstock ithatha i-heavy-duty-duty roller linear guide, ene-rigidity ephezulu yokunyakaza, ukuchaneka kokumisa okuphezulu, kunye nokuzinza okulungileyo okuphantsi kwesantya.

(2) I-Z-axis drive-i-servo motor iqhagamshelwe ngokuthe ngqo kwi-screw yebhola ngokudibanisa, kwaye isikrufu sebhola siqhubela isiqobo sentloko ukuba siye phezulu sisehla kwisali ukuze siqonde i-Z-axis feed. Injini ye-Z-axis inomsebenzi wokuqhawuka oluzenzekelayo. Xa kwenzeka ukusilela kwamandla, i-motor shaft ibanjwe ngokuqinileyo ukukhusela ukuba ingajikelezi.

(3) Iqela le-spindle lithatha i-Taiwan Jianchun i-spindle yokupholisa yangaphakathi ye-speed ephezulu ngokuchaneka okuphezulu kunye nokusebenza okuphezulu. I-shaft engundoqo ibamba imela nge-butterfly spring kwi-shaft engundoqo kunye ne-tension force esebenza kwisikhonkwane sokutsalwa kwesixhobo sokwenza isixhobo ngokusebenzisa indlela ye-broach eneenxalenye ezine, kwaye isixhobo esikhululekile samkela indlela ye-pneumatic.

6)Inkqubo yomoya

Isetyenziselwa ukukhulula isixhobo sokusonta.

7) Ukukhuselwa komatshini

Umzila webhedi (i-X axis) wamkela isikhuselo se-telescopic yensimbi engenasici;

Isikhokelo se-beam (i-Y axis) samkela ukukhuselwa kwelungu eliguquguqukayo.

8) Ukuthambisa

(1) X, Y, Z iibheringi ezine-axis ezintathu zonke ziqatywe igrisi.

(2) X, Y, Z izikhokelo ezine-axis ezintathu zonke zithanjiswa ngeoyile.

(3) X, Y, Z iiperi ze-screw zebhola ezine-axis ezintathu zonke zithanjiswa nge-oyile.

9) Inkqubo ye-CNC

Inkqubo ye-CNC ixhotyiswe ngenkqubo yokulawula ye-Beijing Kaiendi kunye nokuqhuba, kunye nemisebenzi epheleleyo kunye nokusebenza okulula; ujongano lonxibelelwano olusemgangathweni lwe-RS-232, i-socket ye-USB kunye nesoftware ehambelanayo.

Indlela Yokucoca

Esi sixhobo somatshini sixhotyiswe ngenkqubo yokucoca amanzi esembindini, enokucoca ngokufanelekileyo ukungcola kwisipholisi. Inkqubo yangaphakathi yokutshiza amanzi inokuthintela izikhonkwane zentsimbi ukuba zingabotshelelwa kwisixhobo ngexesha lokucutshungulwa, ukunciphisa ukunxitywa kwesixhobo, ukwandisa ubomi besixhobo, kunye nokuphucula ukugqiba komphezulu womsebenzi. Isixhobo sokukhupha iphini lokukhupha amanzi esinoxinzelelo oluphezulu sinokukhusela kakuhle umphezulu wesixhobo sokusebenza, sikhusele isantya esiphezulu esijikelezayo, sithintele ukungcola ekuthinteleni umdibaniso ojikelezayo, kwaye siphucule umgangatho opheleleyo womsebenzi kunye nokuphucula ukusebenza kakuhle. (Qaphela umfanekiso ngumfanekiso obonakalayo wenkqubo yokucoca)

Inkcazo

| Umzekelo | I-BOSM-DPH2016 | I-BOSM-DPH2022 | I-BOSM-DPH2625 | I-BOSM-DPH4026 | |

| Ubungakanani bokusebenza(mm) | 2000*1600 | 2000*2000 | 2500*2000 | 4000*2200 | |

| Max.loading(Kg) | 7000 | 7000 | 7000 | 7000 | |

| T Slot(mm) | 8*22 | 8*22 | 8*22 | 8*22 | |

| Ubuninzi bohambo lwetafile-X umgca ohamba phambili(mm) | 2200 | 2200 | 2600 | 4000 | |

| Ubuninzi bohambo lwetafile-Y umgca ohambahambayo(mm) | 1600 | 2200 | 2500 | 2600 | |

| Ubuninzi be-Spindle stroke-Z i-axis(mm) | 600 | 600 | 600 | 600/1000 | |

| Umgama ukusuka ekupheleni kwespindle ukuya kwitafile yokusebenza(mm) | Ubuninzi | 800 | 800 | 800 | 800 |

| Ubuncinane | 200 | 200 | 200 | 200 | |

| Tapper (7:24) | BT50 | BT50 | BT50 | BT50 | |

| Isantya sokujikeleza(r/min) | 30~3000/60~6000 | 30~3000/60~6000 | 30~3000/60~6000 | 30~3000/60~6000 | |

| Amandla e-Spindle motor (Kw) | 22 | 22 | 22 | 22 | |

| Max. U-U-drill(mm) | φ90 | φ90 | φ90 | φ90 | |

| Ucofa kakhulu(mm) | M36 | M36 | M36 | M36 | |

| Ukusika isantya feed feed | 1-4000 | 1-4000 | 1-4000 | 1-4000 | |

| Intshukumo ekhawulezayo(m/min) | 2008/8/8 | 2008/8/8 | 2008/8/8 | 2008/8/8 | |

| Ukuphunyezwa kwemigangatho yesizwe GB/T18400.4(m/min) | ±0.01/1000mm | ±0.01/1000mm | ±0.01/1000mm | ±0.01/1000mm | |

| Ubunzima(T) | 16.5 | 21 | 24 | 40 | |

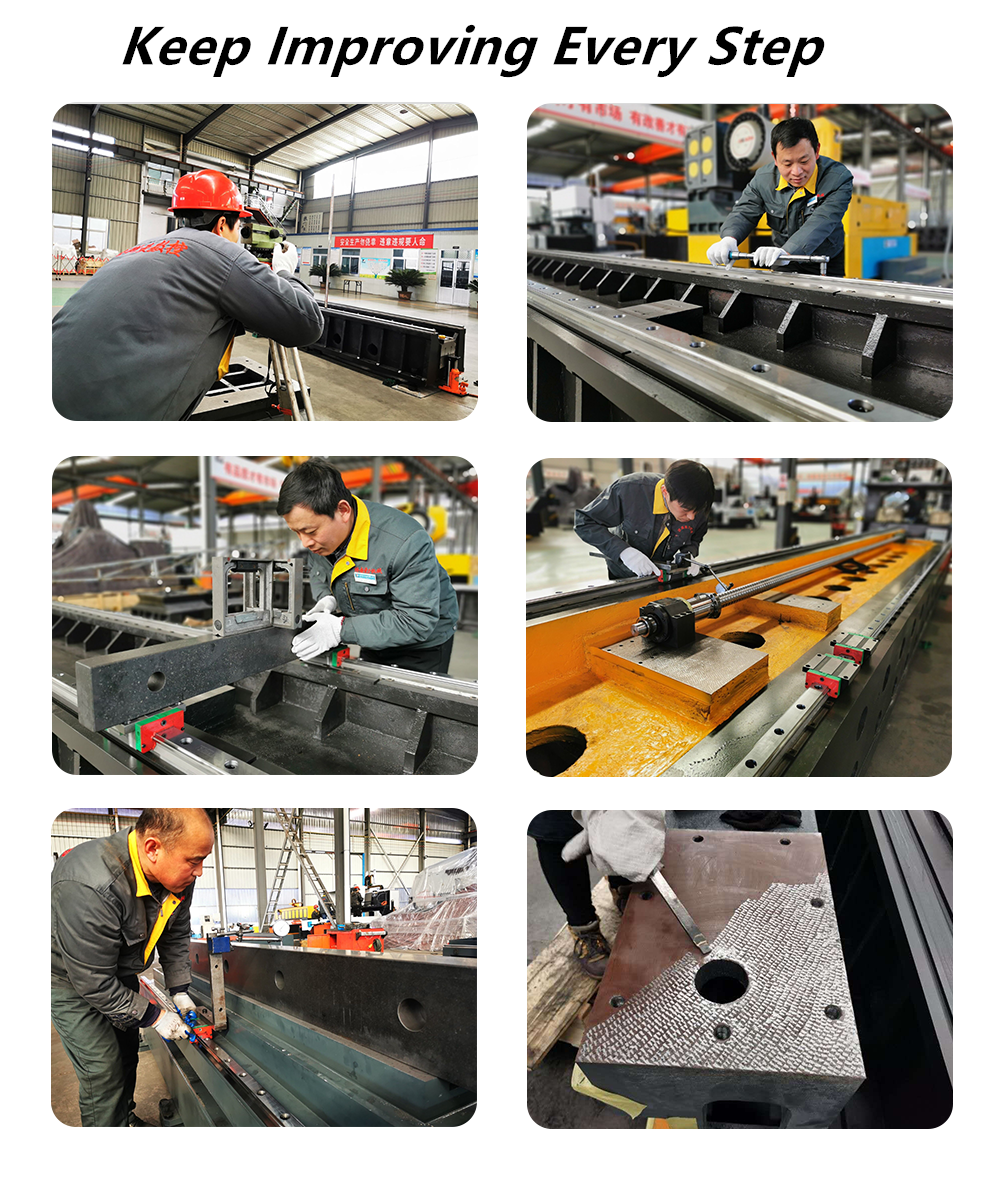

Ukuhlolwa koMgangatho

Umatshini ngamnye we-Bosman ulinganiswe nge-laser interferometer evela kwinkampani yase-United Kingdom ye-RENISHAW, ehlola ngokuchanekileyo kwaye ihlawule iimpazamo ze-pitch, i-backlash, ukuchaneka kwendawo, kunye nokuphindaphinda ukuchaneka kokumisa ukuqinisekisa ukuguquguquka komatshini, ukuzinza kwe-static, kunye nokucubungula ukuchaneka. . Uvavanyo lwebha yebhola Umatshini ngamnye usebenzisa umvavanyi webha yebhola evela kwinkampani yaseBritani ye-RENISHAW ukulungisa ukuchaneka kwesangqa sokwenyani kunye nokuchaneka komatshini wejometri, kwaye wenze imifuniselo yokusika setyhula ngaxeshanye ukuqinisekisa ukuchaneka komatshini we-3D kunye nokuchaneka kwesangqa.

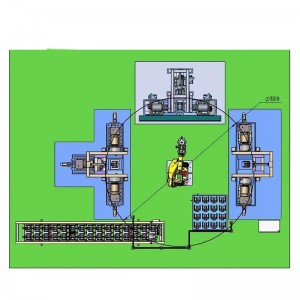

Indawo yokusetyenziswa kwesixhobo somatshini

1.1 Izixhobo zokusingqongileyo iimfuno

Ukugcina iqondo elingaguqukiyo lobushushu be-ambient yinto eyimfuneko kumatshini ochanekileyo.

(1) Ubushushu obukhoyo bendawo yi -10℃ ~35 ℃. Xa ubushushu be-ambient bungama-20℃, ukufuma kufuneka kube ngama-40~75%.

(2) Ukuze kugcinwe ukuchaneka kwe-static kwesixhobo somatshini ngaphakathi koluhlu oluchaziweyo, ubushushu obuphezulu be-ambient kufuneka bube yi-15.° C ukuya kuma-25° C kunye nomahluko wobushushu

Akufunekanga igqithe± 2 ℃/ 24h.

1.2 Umbane wokubonelela ngombane: i-3-phase, i-380V, i-voltage fluctuation ngaphakathi± I-10%, i-frequency supply frequency: 50HZ.

1.3 Ukuba i-voltage kwindawo yokusetyenziswa ayizinzile, isixhobo somatshini kufuneka sixhotyiswe umbane olawulwayo ukuze kuqinisekiswe ukusebenza okuqhelekileyo kwesixhobo somatshini.

1.4. Isixhobo somatshini kufuneka sibe nesiseko esithembekileyo: ucingo lokumisa lucingo lobhedu, ububanzi bocingo akufanele kube ngaphantsi kwe-10mm.², kwaye ukuxhathisa umhlaba kungaphantsi kwe-4 ohms.

1.5 Ukuze kuqinisekiswe ukusebenza okuqhelekileyo kwesixhobo, ukuba umoya ocinezelweyo womthombo womoya uyasilela ukuhlangabezana neemfuno zomthombo womoya, iseti yezixhobo zokucoca umthombo womoya (i-dehumidification, degreasing, filtering) kufuneka yongezwe phambi kokuba umoya wokungena kumatshini.

1.6. Izixhobo kufuneka zigcinwe kude nelanga elithe ngqo, ukungcangcazela kunye nemithombo yokushisa, kwaye kude neejeneretha eziphezulu ze-frequency, oomatshini be-welding yombane, njl., ukwenzela ukuba ugweme ukusilela kokuvelisa umatshini okanye ukulahleka kokuchaneka komatshini.

Ngaphambi nasemva kweNkonzo

1)Ngaphambi kweNkonzo

Ngokufunda isicelo kunye nolwazi oluyimfuneko kubathengi emva koko impendulo kwiinjineli zethu, iqela le-Bossman Technical lijongene nonxibelelwano lobugcisa kunye nabathengi kunye nokuqulunqwa kwezisombululo, ukuncedisa umthengi ekukhetheni isisombululo esifanelekileyo somatshini kunye noomatshini abafanelekileyo.

2)Emva kweNkonzo

A.Umatshini onewaranti yonyaka omnye kwaye uhlawulwe ulondolozo lobomi bonke.

B.Ngexesha lewaranti yonyaka omnye emva kokuba umatshini efikile kwindawo ekuyiwa kuyo, iBOSSMAN iya kubonelela ngeenkonzo zokugcinwa kwasimahla kunye nexesha elifanelekileyo kwiimpazamo ezahlukeneyo ezingenziwanga ngabantu kumatshini, kwaye zibuyisele ngexesha elifanelekileyo zonke iintlobo zomonakalo owenziwe ngumntu simahla. yentlawulo . Ukusilela okwenzeka kwixesha lewaranti kuya kulungiswa ngeentlawulo ezifanelekileyo.

Inkxaso ye-C.Technical kwiiyure ezingama-24 kwi-intanethi, i-TM, i-Skype, i-E-mail, ukusombulula imibuzo ehambelanayo ngexesha. ukuba ayinasombululo, iBOSSMAN iya kulungiselela kwangoko ukuba injineli yasemva kokuthengisa ifike kwindawo ukuze ilungiswe, umthengi ufuna ukuhlawulela iVISA, amatikiti eenqwelomoya kunye nendawo yokuhlala.

Isiza soMthengi