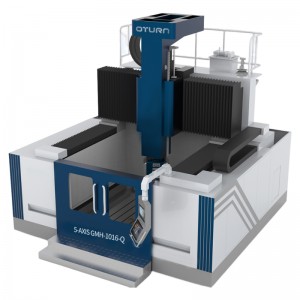

CNC Profile Machining Centre

CNC Profile Machining Centre

Umatshini woKumba we-CNC

Iimpawu zoomatshini

Bosm DC seriesCNC ukomba kunye noomatshini bokusilazisetyenziselwa ikakhulu ukugaya okusebenzayo kunye nokucofa ii-workpieces ezinobubanzi bezinto ezihambelanayo ngaphakathi koluhlu olusebenzayo. Ngomngxuma kunye nomngxuma oyimfama unokugrunjwa kwiindawo eziphathekayo kunye nezinto ezidibeneyo. Ukulungiswa komatshini kunye nomlawuli we-CNC, ukusebenza kulula kakhulu. Iyakwazi ukuqonda i-automation, ukuchaneka okuphezulu, iindidi ezininzi kunye nemveliso yobuninzi.

Ukuze kuhlangatyezwane neemfuno zokusetyenzwa kwabasebenzisi abohlukeneyo, inkampani yethu iphuhlise iintlobo ezahlukeneyo zeemveliso ezigqityiweyo.Inokuthi iyilwe kwaye ilungiselelwe ngokweemfuno zabasebenzisi.

Ulwakhiwo lomatshini

Isixhobo ikakhulu siqulunqwe yitafile yokulala, i-gantry ehambayo, i-saddle mobile, i-drilling kunye nentloko yamandla okugaya, isixhobo sokuthambisa ngokuzenzekelayo kunye nesixhobo sokukhusela, isixhobo sokupholisa esijikelezayo, inkqubo yokulawula idijithali, inkqubo ye-hydraulic, inkqubo yombane, njl njl. Isixhobo somatshini sinendawo ephezulu. ukuchaneka kunye nokuphindaphinda ukuchaneka kokubeka.

1. Ibhedi &netafile yokusebenza:

Ibhedi yomatshini i-welded steel structure parts, kwaye isakhelo esiphambili sicutshungulwa ngamalungu esakhiwo sensimbi. Emva kokuba uxinzelelo lwangaphakathi lususwe ngonyango lobushushu bokwaluphala, lunokuqina okuguquguqukayo kunye nokuqina kwaye akukho deformation. Itafile yokusebenza yenziwe ngentsimbi yokugalela iHT250. Itafile yokusebenza ingasetyenziselwai-clamping workpieces. Inokuthi ixhotyiswe nge-pneumatic fixture, ekulungele ngakumbi kwaye ikhawuleza ukubethelela izixhobo zokusebenza,. Awona mandla aphezulu etafile yokusebenza yitoni enye. Icala eliphezulu lasekhohlo lebhedi lifakwe ngokuthe nkqo kunye nezixhobo ezimbini ezithwele i-ultra-high eziqengqelekayo izibini zesikhokelo kunye nerack echanekileyo. I-motor ye-gantry iqhutywa yi-AC servo system kunye ne-rack system kwi-X direction. Iibholiti ezilungelelanisiweyo zisasazwa kumphezulu ophantsi webhedi, onokuthi ulungelelanise ngokulula umgangatho wetafile yokulala.

2. Ukuhambisa i-cantilever:

I-gantry ehambayo ye-cantilever ene-cast iron structure icutshungulwa emva kokususa uxinzelelo lwangaphakathi ngonyango olushushu olwenziweyo oluguga, olunoguquko oluhle kunye nokuqina kwe-static kwaye akukho deformation. Izibini ezimbini zesikhokelo ezijikelezayo kunye ne-ultra-high-high bearing capacity ifakwe emacaleni angaphambili nangaphezulu kwi-gantry. Isikhokelo esijikelezayo esine-ultra-high, isethi ye-screw yebhola echanekileyo kunye ne-servo motor ifakwe phezulu ukwenza i-plate yesilayidi yentloko yamandla ihambe kwi-Y-axis direction. Intloko yamandla okomba ifakwe kwipleyiti yesilayidi yentloko yamandla. Ukuhamba kwe-gantry kufezekiswa ngokujikeleza kwe-screw yebhola eqhutywe yi-servo motor ngokusebenzisa ukudibanisa.

3. Isali ehambayo:

Isali yokutyibilika eshukumayo lilungu lolwakhiwo lwentsimbi. Izibini ezimbini eziqengqelekayo zesikhokelo esine-ultra-high, iseti ye-screw yebhola echanekileyo kunye ne-servo motor ifakwe kwisali yokutyibilika ukuze iqhube intloko yamandla okomba ukuze ihambe kwicala le-z-axis, enokuqonda ukuya phambili ngokukhawuleza, sebenzela phambili, umva ngokukhawuleza kwaye umise intloko yamandla. Inemisebenzi yokwaphuka kwetshiphu ngokuzenzekelayo, ukususa itshiphu kunye nokunqumama.

I-servo spindle motor ekhethekileyo isetyenziselwa ukomba intloko yamandla. I-spindle ekhethekileyo echanekileyo iqhutywa yibhanti ye-synchronous ene-toothed ukuqonda utshintsho oluguquguqukayo lwesantya esingenanyathelo. Ukutya kuqhutywa yi-servo motor kunye nebhola screw.

I-y-axis inokudityaniswa kwaye ilawulwe ngesiqingatha se-loop evaliweyo, enokuqonda i-linear ne-circular interpolation. Isiphelo esiphambili se-shaft yi-er taper hole yokugoba i-drill okanye i-milling cutter, ngokuchaneka okuphezulu, ukusika isantya esiphezulu, isixhobo sokutshintsha isixhobo somoya, ngokuzikhethela kunye nemagazini yesixhobo sohlobo lomnqwazi, umthamo wemagazini yesixhobo sesibhozo, utshintsho lwesixhobo lulula ngakumbi, inqanaba eliphezulu lokuzenzekelayo. yokwenziwa ngesandla.

5. Isixhobo sokuthambisa esizenzekelayo kunye nesixhobo sokukhusela:

Umatshini uxhotyiswe ngesixhobo sokuthambisa ngokuzenzekelayo, esinokuthambisa ngokuzenzekelayo izibini ezihambayo ezifana nomzila wesikhokelo, i-screw lead kunye ne-rack. I-x-axis kunye ne-Y-axis yesixhobo somatshini zixhotyiswe ngesigqubuthelo sokukhusela sothuli, kwaye i-splash baffle engangeni manzi ifakwe malunga netafile yokusebenza.

6. Inkqubo yoLawulo lwe-KND:

6.1. Ngomsebenzi wokuqhekeka kwetshiphu, ixesha lokuqhekeka kwetshiphu kunye nomjikelo wokuqhekeka kwetshiphu unokusetwa kujongano lomatshini womntu.

6.2. Ngeumsebenzi wokuphakamisa isixhobo, isixhobo sokuphakamisa ukuphakama sinokusetwa kujongano lomatshini womntu. Xa ubhobhoza kulo mphakamo, i-drill bit iphakanyiselwa ngokukhawuleza phezulu kwi-workpiece, emva koko i-chip iphoswe, kwaye emva koko ikhawuleze ukuya kwindawo yokugaya kwaye iguqulelwe ngokuzenzekelayo ibe yinkqubela phambili yomsebenzi.

6.3. Ibhokisi yolawulo yokusebenza esembindini kunye neyunithi ephathwayo ixhotyiswe ngenkqubo yeCNC, ujongano lwe-USB kunye nesikrini seLCD. Ukuze kuququzelelwe inkqubo, ukugcinwa, umboniso kunye nokunxibelelana, i-interface yokusebenza inemisebenzi ye-dialogue ye-man-machine, imbuyekezo yephutha kunye ne-alarm ngokuzenzekelayo.

6.4. Isixhobo sinomsebenzi wokujonga kwangaphambili kunye nokujonga kwakhona indawo yomngxuma phambi komatshini, ngoko ke ukusebenza kulula kakhulu.

Inkcazo

| Umzekelo | I-BOSM-DC60050 | |

| Max. ubungakanani bomsebenzi | Ubude × ububanzi (mm) | 2600×500 |

| Inkunzi ethe nkqo yokomba intloko yamandla | Ubuninzi (iqhekeza) | 1 |

| Umngxuma we-spindle taper | BT40 | |

| Idayamitha yokomba (mm) | Φ2-Φ26 | |

| Isantya sokujikeleza (R / min) | 30-3000 | |

| Amandla e-spindle (kw) | 15 | |

| Umgama phakathi kwempumlo yokusonta kunye netafile yokusebenza (mm) | 150-650mm | |

| I-X-axis (uhambo olusecaleni) | Esona siphumo siphezulu (mm) | 500 |

| Isantya esihambayo se-X (M / min) | 0~9 | |

| I-X-axis servo motor amandla (kw) | 2.4*1 | |

| I-Y-axis(intshukumo yekholamu yobude) | Esona siphumo siphezulu (mm) | 2600 |

| Isantya esihambayo se-Y-axis (M / min) | 0~9 | |

| Amandla e-y-axis servo motor (kw) | 2.4*1 | |

| Umgca we-Z | Esona siphumo siphezulu (mm) | 500 |

| Isantya esishukumayo se-z axis (M / min) | 0~8 | |

| I-Z-axis servo motor amandla (kw) | 1 × 2.4 nge brake | |

| Ubungakanani bomatshini | Ubude × ububanzi × ubude (mm) | 5400×2180×2800 |

| Ukubeka ukuchaneka | X/Y/Z | ±0.05/300mm |

| Ukuphindaphinda ukuchaneka kokubekwa | X/Y/Z | ±0.025/300mm |

| Ubunzima obupheleleyo (t) | 4.5 | |

Ukuhlolwa koMgangatho

Umatshini ngamnye ulinganiswe nge-laser interferometer evela kwinkampani yase-United Kingdom ye-RENISHAW, ehlola ngokuchanekileyo kwaye ihlawule iimpazamo ze-pitch, i-backlash, ukuchaneka kokumisa, kunye nokuphindaphinda ukuchaneka kokumisa ukuqinisekisa ukuguquguquka komatshini, ukuzinza kwe-static, kunye nokucubungula ukuchaneka. . Uvavanyo lwebha yebhola Umatshini ngamnye usebenzisa umvavanyi webha yebhola evela kwinkampani yaseBritani ye-RENISHAW ukulungisa ukuchaneka kwesangqa sokwenyani kunye nokuchaneka komatshini wejometri, kwaye wenze imifuniselo yokusika setyhula ngaxeshanye ukuqinisekisa ukuchaneka komatshini we-3D kunye nokuchaneka kwesangqa.

Indawo yokusetyenziswa kwesixhobo somatshini

1.1 Izixhobo zokusingqongileyo iimfuno

Ukugcina iqondo elingaguqukiyo lobushushu be-ambient yinto eyimfuneko kumatshini ochanekileyo.

(1) Ubushushu obukhoyo be-ambient yi -10 ℃ ~ 35 ℃. Xa ubushushu be-ambient bungama-20 ℃, ukufuma kufuneka kube yi-40 ~ 75%.

(2) Ukuze kugcinwe ukuchaneka okumileyo kwesixhobo somatshini ngaphakathi koluhlu oluchaziweyo, elona qondo lobushushu lendawo lifuneka ukuba libe yi-15 ° C ukuya kuma-25 ° C kunye nomahluko wobushushu.

Akufunekanga idlule ± 2 ℃ / 24h.

1.2 Amandla ombane ombane: isigaba se-3, i-380V, ukuguquguquka kombane ngaphakathi kwe-± 10%, i-frequency supply frequency: 50HZ.

1.3 Ukuba i-voltage kwindawo yokusetyenziswa ayizinzile, isixhobo somatshini kufuneka sixhotyiswe umbane olawulwayo ukuze kuqinisekiswe ukusebenza okuqhelekileyo kwesixhobo somatshini.

1.4. Isixhobo somatshini kufuneka sibe nesiseko esithembekileyo: ucingo lokumisa lucingo lobhedu, ububanzi bocingo akufunekanga lube ngaphantsi kwe-10mm², kwaye ukuxhathisa komhlaba kungaphantsi kwe-4 ohms.

1.5 Ukuze kuqinisekiswe ukusebenza okuqhelekileyo kwesixhobo, ukuba umoya ocinezelweyo womthombo womoya uyasilela ukuhlangabezana neemfuno zomthombo womoya, iseti yezixhobo zokucoca umthombo womoya (i-dehumidification, degreasing, filtering) kufuneka yongezwe phambi kokuba umoya wokungena kumatshini.

1.6. Izixhobo kufuneka zigcinwe kude nelanga elithe ngqo, ukungcangcazela kunye nemithombo yokushisa, kwaye kude neejeneretha eziphezulu ze-frequency, oomatshini be-welding yombane, njl., ukwenzela ukuba ugweme ukusilela kokuvelisa umatshini okanye ukulahleka kokuchaneka komatshini.

Ngaphambi nasemva kweNkonzo

1)Ngaphambi kweNkonzo

Ngokufunda isicelo kunye nolwazi oluyimfuneko kubathengi emva koko impendulo kwiinjineli zethu, iqela le-Bossman Technical lijongene nonxibelelwano lobugcisa kunye nabathengi kunye nokuqulunqwa kwezisombululo, ukuncedisa umthengi ekukhetheni isisombululo esifanelekileyo somatshini kunye noomatshini abafanelekileyo.

2)Emva kweNkonzo

A.Umatshini onewaranti yonyaka omnye kwaye uhlawulwe ulondolozo lobomi bonke.

B.Ngexesha lewaranti yonyaka omnye emva kokuba umatshini efikile kwindawo ekuyiwa kuyo, iBOSSMAN iya kubonelela ngeenkonzo zokugcinwa kwasimahla kunye nexesha elifanelekileyo kwiimpazamo ezahlukeneyo ezingenziwanga ngabantu kumatshini, kwaye zibuyisele ngexesha elifanelekileyo zonke iintlobo zomonakalo owenziwe ngumntu simahla. yentlawulo . Ukusilela okwenzeka kwixesha lewaranti kuya kulungiswa ngeentlawulo ezifanelekileyo.

Inkxaso ye-C.Technical kwiiyure ezingama-24 kwi-intanethi, i-TM, i-Skype, i-E-mail, ukusombulula imibuzo ehambelanayo ngexesha. ukuba ayinasombululo, iBOSSMAN iya kulungiselela kwangoko ukuba injineli yasemva kokuthengisa ifike kwindawo ukuze ilungiswe, umthengi ufuna ukuhlawulela iVISA, amatikiti eenqwelomoya kunye nendawo yokuhlala.

Isiza soMthengi