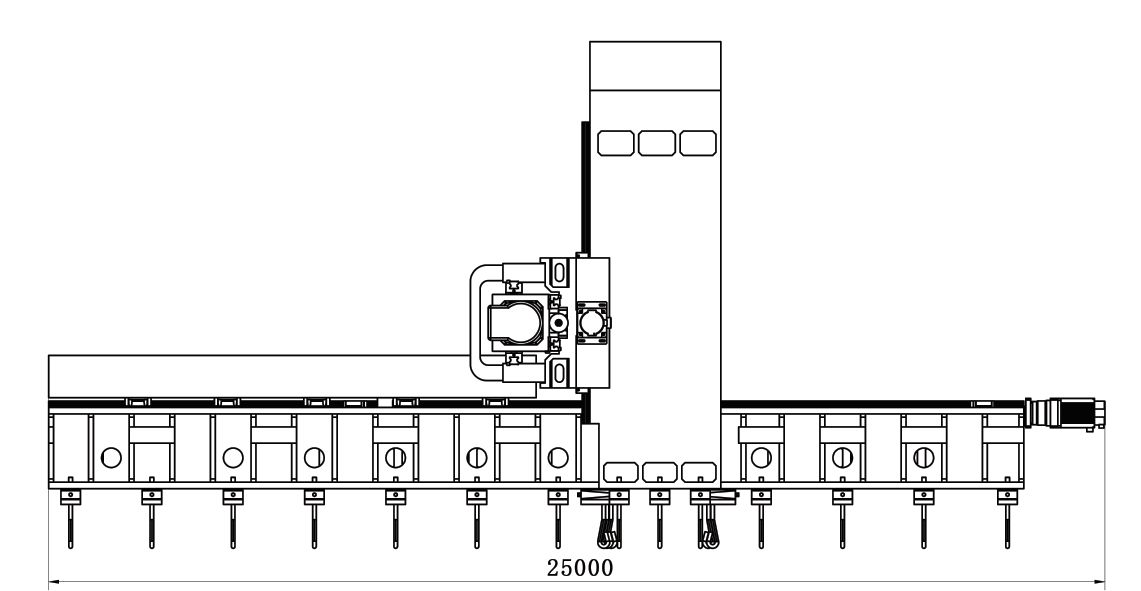

I-BOSM -12010 Ichasa-iNtloko iBoring Milling Machine

1. Ukusetyenziswa kweumatshini :

I-BOSM- 12000 * 1000 i-fixed-beam ye-CNC gantry i-double-column-head-to-head boring kunye nomatshini wokusila sisixhobo esikhethekileyo somatshini wokucubungula iingalo ze-excavator / iintonga. Umqamelo, unokuqonda ukucutshungulwa ngokukhawuleza kwe-workpiece, i-workpiece inokugrunjwa, igaywe, kwaye idikwe ngaphakathi koluhlu lwe-stroke olusebenzayo, i-workpiece inokucutshungulwa endaweni ngexesha elinye (akukho mfuneko yokubamba okwesibini), isantya sokulayisha kunye nokukhulula. iyakhawuleza, isantya sokumisa siyakhawuleza, kwaye ukuchaneka kokucubungula kuphezulu. Umgangatho ophezulu, ophezulu wokusebenza kakuhle.

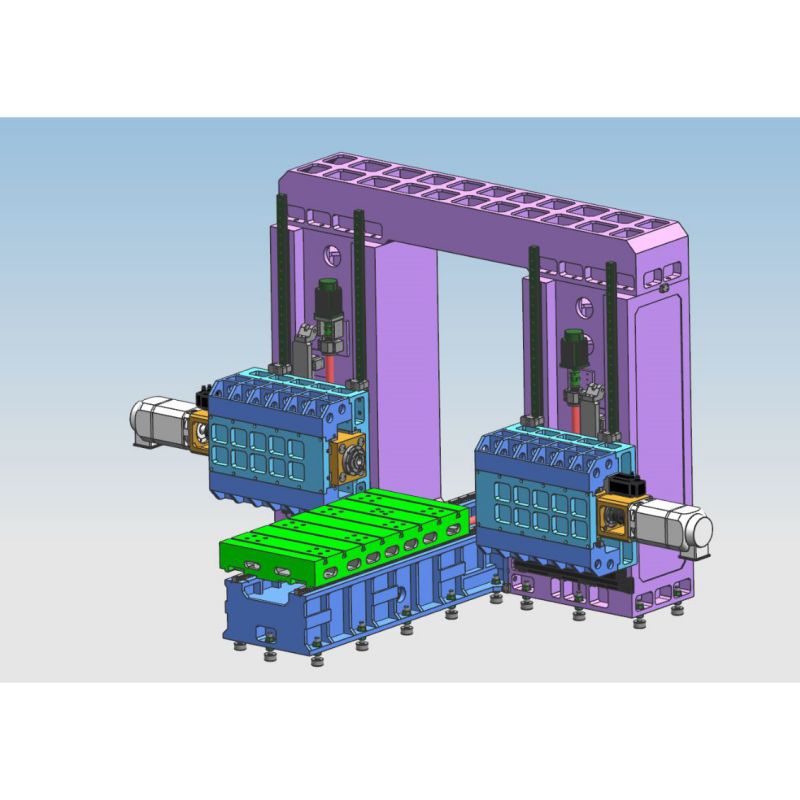

2.Ubume bomatshiniIimbonakalo:

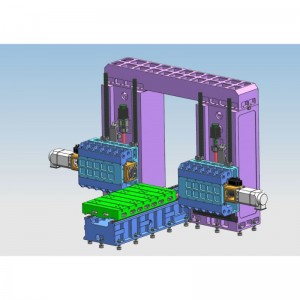

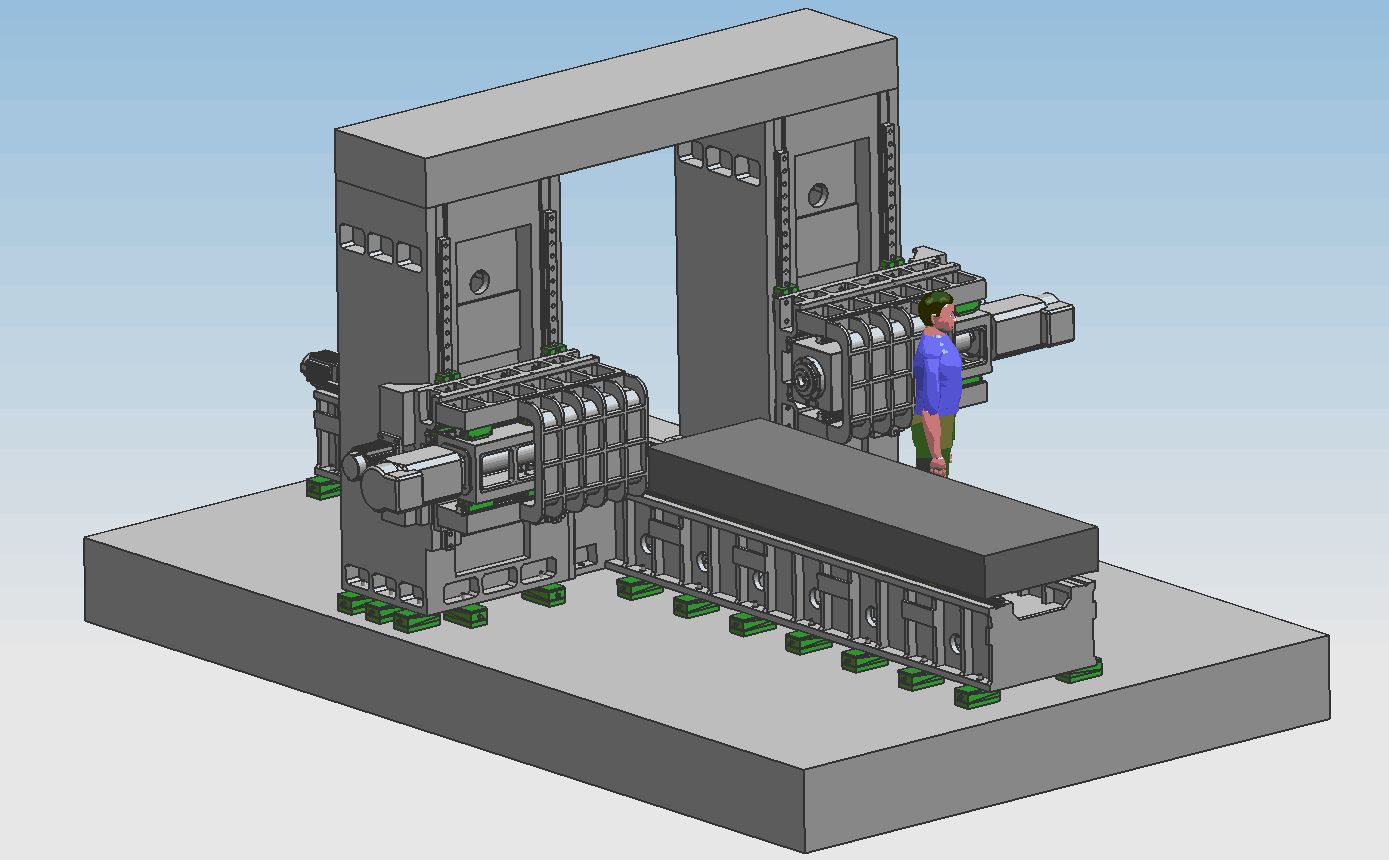

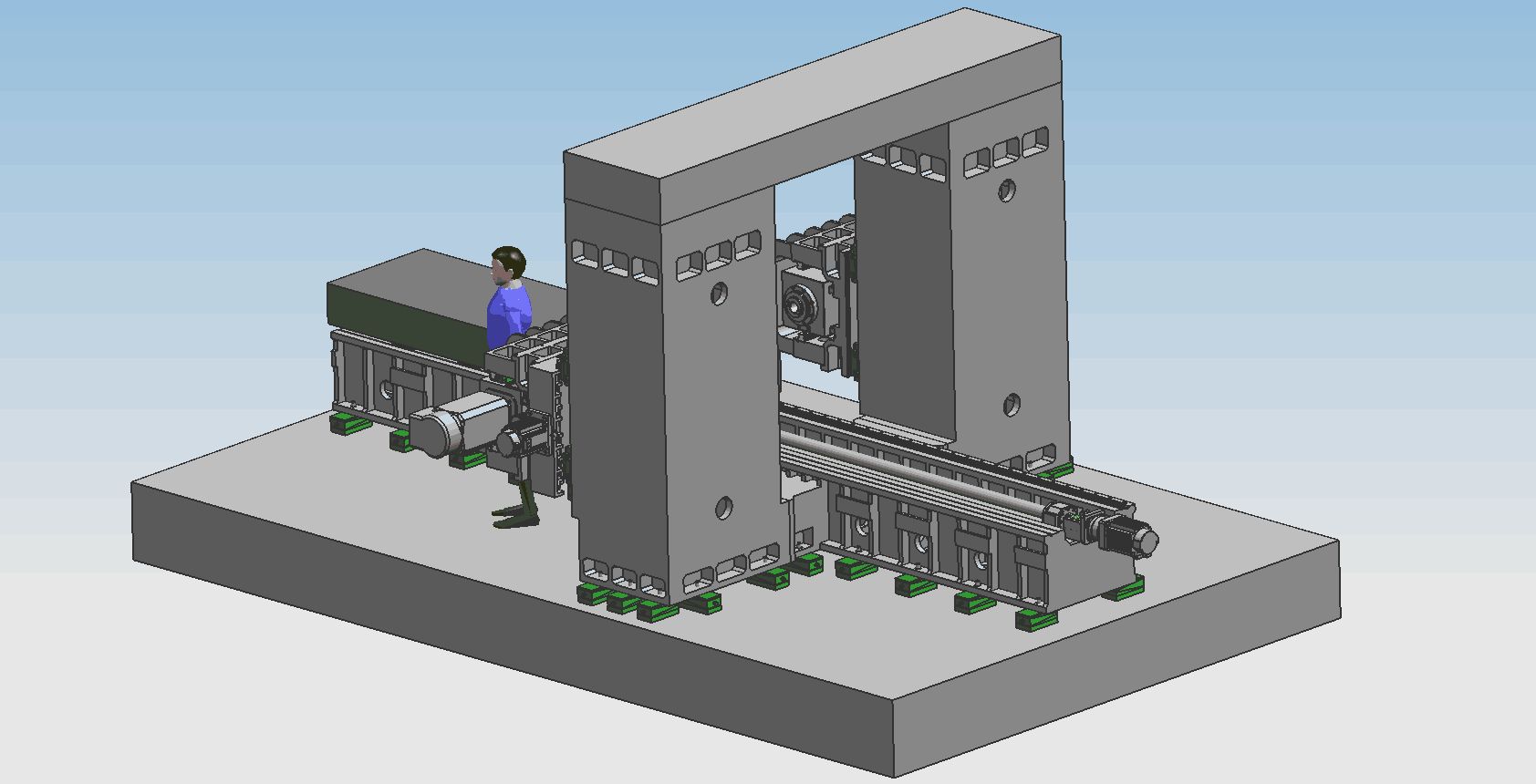

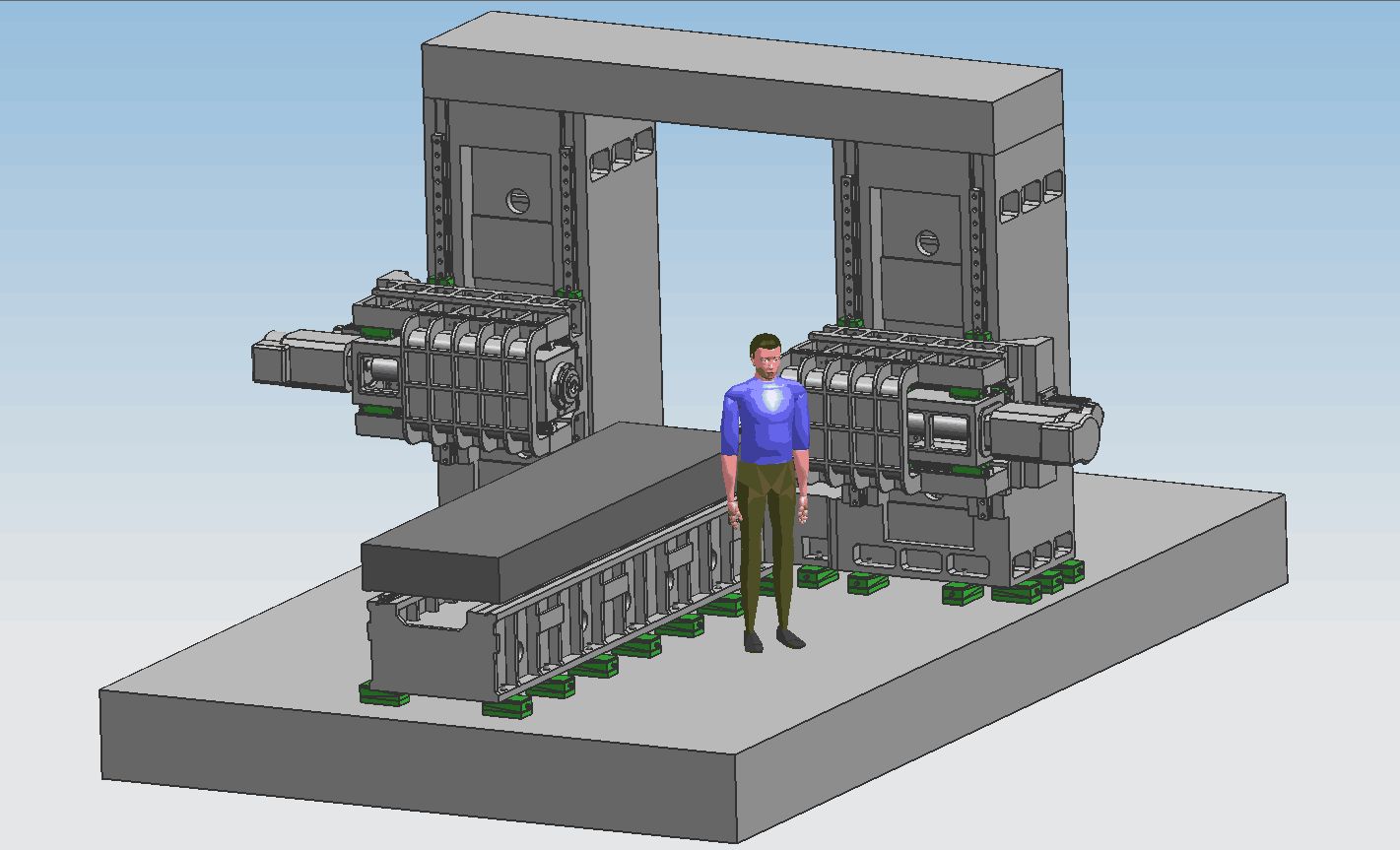

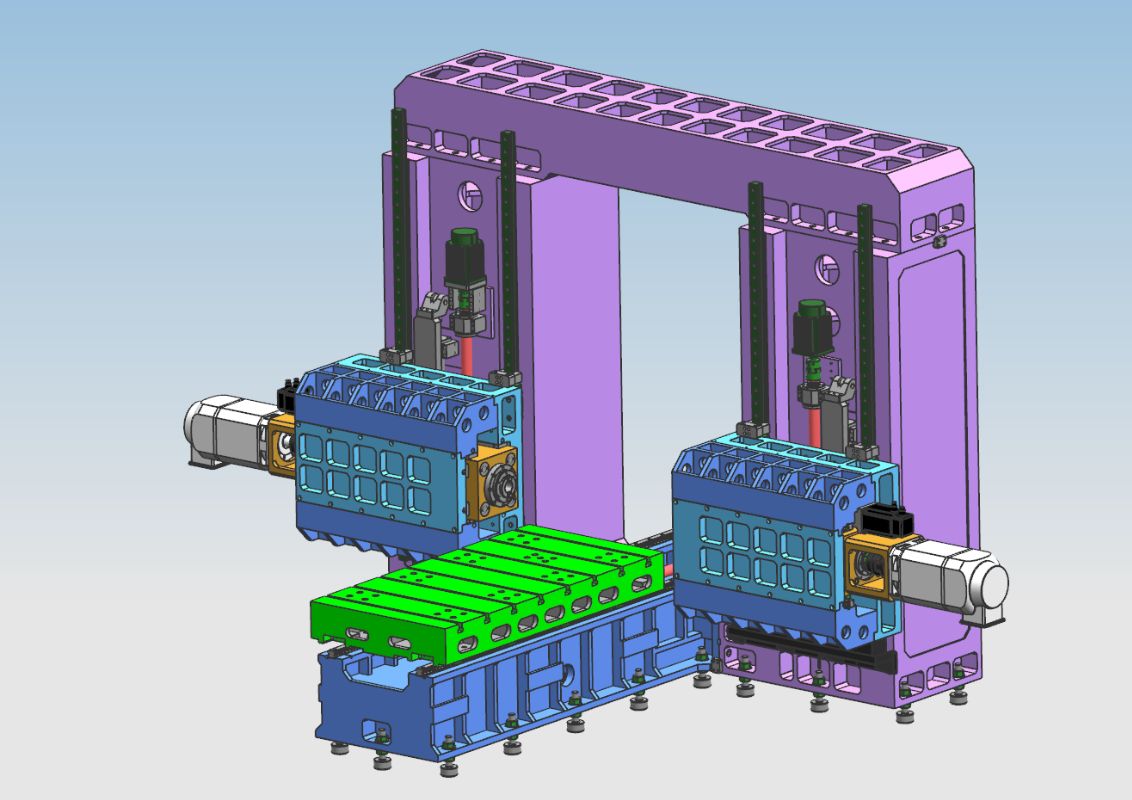

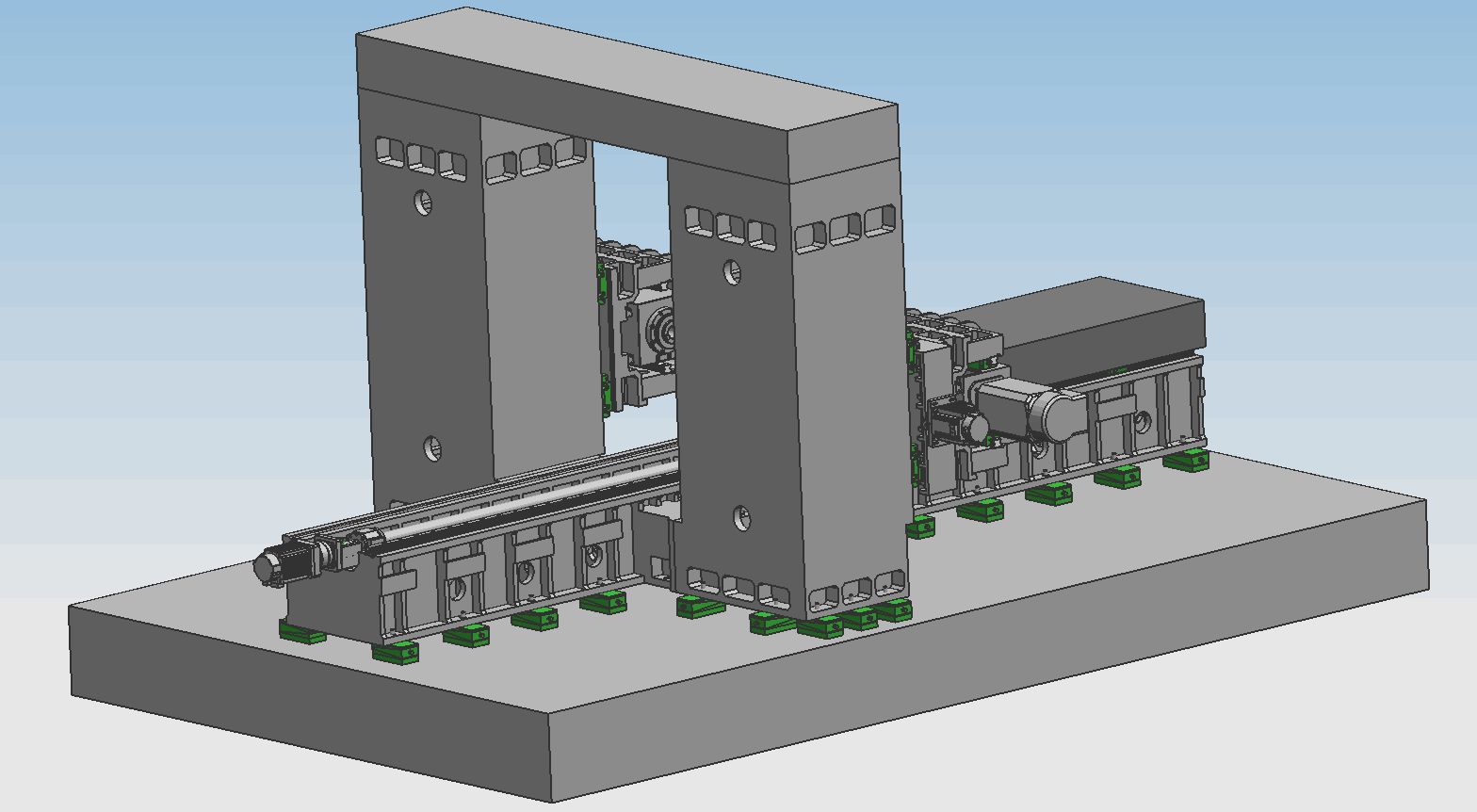

Amacandelo aphambili esixhobo somatshini: ibhedi, ibhentshi yokusebenzela, iikholamu ezisekhohlo nasekunene, imiqadi, imiqadi yokudibanisa igantry, iisali, iinkunzi zeegusha, njl. umngxuma wesanti → ukungcangcazela ukuguga → ukunyangwa kobushushu Ibhedi esisigxina, iikholomu ezisekhohlo nasekunene, i-gantry, kunye ne-workbench move; Inemisebenzi yokugaya, i-boring, i-drilling, i-countersinking, i-tapping, njl. Indlela yokupholisa isixhobo kukupholisa kwangaphandle. Isixhobo somatshini siqulethe ii-axes ze-5 zokutya, ezinokuqonda ukudibanisa kwe-4-axis kunye ne-5-axis enye-action. Kukho iintloko zamandla ezi-2. I-axis yesixhobo somatshini kunye nentloko yamandla iboniswe kumzobo ongezantsi.

2.1.Isakhiwo esiphambili se-axial transmission feed part

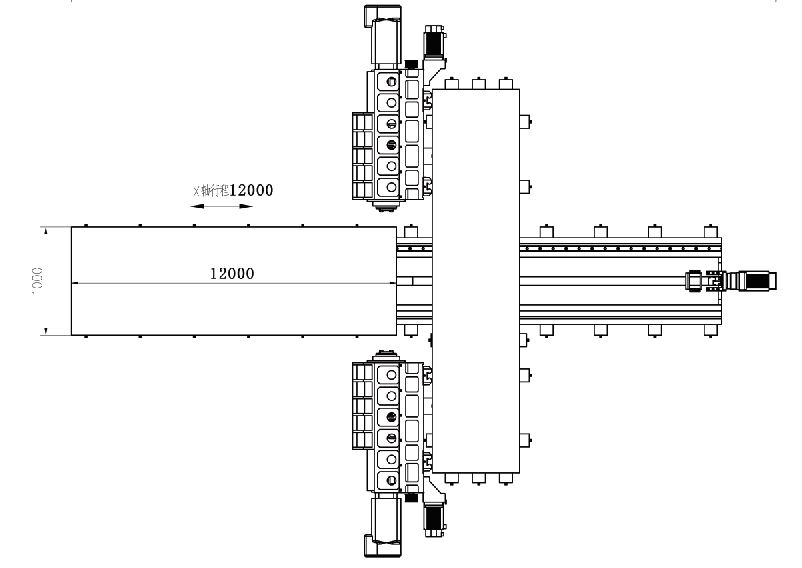

2.1.1.I-X-axis:I-worktable iphinda ibuyele ecaleni ecaleni komzila wesikhokelo sombhede osisigxina.

I-X 1-i-axis drive: I-AC servo motor kunye ne-high-chane-chane isinciphisi seplanethi siqhutywa sisikrufu sebhola ukuqhuba intshukumo yebhentshi yokusebenzela ukuqonda intshukumo yomda we-X-axis.

Ifomu yesikhokelo sikaloliwe: beka iileyili ezimbini zesikhokelo ezichanekileyo ezichanekileyo.

2.1.2 Umgca we-Z1:Intloko yamandla kunye nesali zifakwe ngokuthe nkqo kwicala langaphambili lekholamu, kwaye zibuyisela phezulu naphantsi ecaleni komzila wesikhokelo sekholamu.

Ukuhanjiswa kwe-Z1-axis: I-AC servo motor kunye nevili elihambelanayo zisetyenziselwa ukuqhuba isikrufu sebhola ukuqhuba isali ukuqonda intshukumo yomgca we-Z-axis

2.1.3 umgca we-Z2:Intloko yamandla kunye nesali zifakwe ngokuthe nkqo kwicala langaphambili lekholamu, kwaye zibuyisela phezulu naphantsi ecaleni komzila wesikhokelo sekholamu.

Ukuhanjiswa kwe-Z2-axis: I-AC servo motor kunye nevili elihambelanayo zisetyenziselwa ukuqhuba isikrufu sebhola ukuqhuba isali ukuze kuqatshelwe i-Z- axis linear motion.

2.1.4 Umgca we-Y1:Isali yentloko yamandla ifakwe ngokuthe nkqo kwicala langaphambili lekholamu yasekunene, kwaye ibuyisela ngasekhohlo nasekunene ecaleni komgaqo kaloliwe wekholamu.

I-Y1-axis transmission: I-AC servo motor kunye ne-high-chane-high-precision reducer yeplanethi isetyenziselwa ukuqhuba inkunzi yegusha ukuba ihambe ngesijiko sebhola ukuqonda intshukumo yomgca we-Y1- axis.

2.1.5 Y2 umgca ohamba phakathi:Isali yentloko yamandla ifakwe ngokuthe nkqo kwicala langaphambili lekholamu yasekunene, kwaye ibuyisela ngasekhohlo nasekunene ecaleni komgaqo kaloliwe wekholamu.

Ukuhanjiswa kwe-Y2-axis: I-AC servo motor kunye ne-high-chane-chane isinciphisi seplanethi isetyenziselwa ukuqhuba inkunzi yegusha ukuba ihambe nge-screw yebhola ukuze iqonde intshukumo ye-Y2- axis linear.

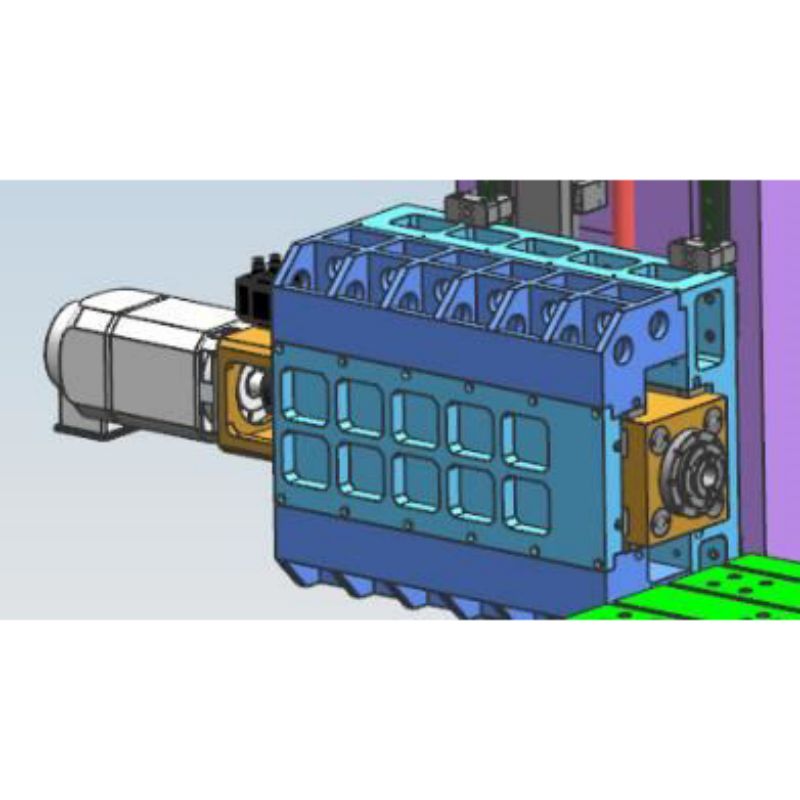

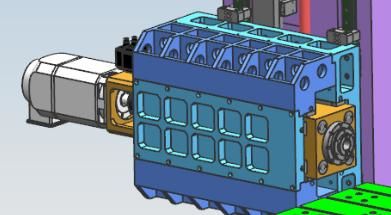

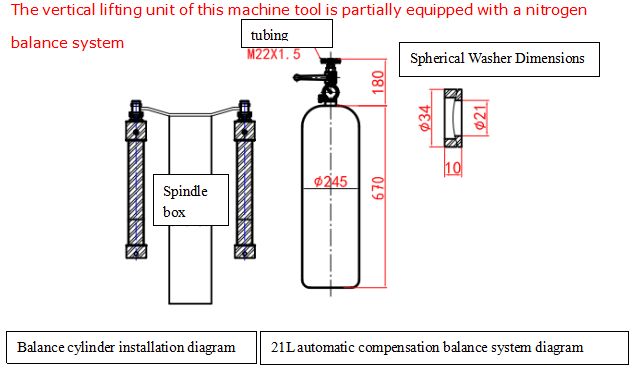

2.2.Isalathiso esishukumayo sentloko ye-drilling kunye ne-milling power (kubandakanywa nentloko yamandla 1 kunye ne-2) ithatha isakhiwo senqama yesikwele, eyona ndlela iphakamileyo ye-wire-hard edityanisiweyo yomzila wesitimela, umzila onzima ujikelezwe yinkxaso eqinile, i-4 linear linear roller guide. izibini zikhokelwa, kwaye i-drive ithatha i-AC servo motor Qhuba ibhanti le-synchronous (i = 2) kunye nokudluliselwa kwe-screw yebhola echanekileyo, intloko yamandla ithatha i-servo motor ukuba ihlehlise ngebhanti ye-synchronous kunye nevili elihambelanayo, likhokelwa ngumsebenzi ochanekileyo. isikhokelo sikaloliwe iperi, kwaye uqhuba nkqo jija ibhola ukujikeleza, ukuqonda intloko amandla Yenza phezulu nasezantsi intshukumo nkqo, kwaye ixhotyiswe ibhali nitrogen ukunciphisa umthamo wokuthwala intloko umatshini kwi screw kunye servo motor. Injini ye-Z-axis inomsebenzi wokuqhawuka oluzenzekelayo. Kwimeko yokusilela kwamandla, i-automatic brake iya kubamba i-motor shaft ngokuqinileyo. , ukuze ingabi nakujikeleza. Xa usebenza, xa i-drill bit ingabambi i-workpiece, iya kutya ngokukhawuleza; xa i-drill bit ichukumisa i-workpiece, iya kutshintshela ngokuzenzekelayo kwisondlo esisebenzayo. Xa i-drill bit ingena kwi-workpiece, iya kutshintshela ngokuzenzekelayo kwi-rewind ngokukhawuleza; xa isiphelo se-drill bit sishiya i-workpiece kwaye sifikelele kwindawo emiselweyo, i-worktable iya kuhamba kwindawo elandelayo yomngxuma ukuqonda ukujikeleza okuzenzekelayo. Intloko yamandla ithatha indibaniselwano yocingo kunye nomzila onzima, ongaqinisekisi nje isantya sokuhamba kwezixhobo, kodwa kwandisa kakhulu ukuqina kwezixhobo . Kwaye inokuqonda imisebenzi yokwemba umngxuma oyimfama, ukugaya, ukubetha, ukuqhekeza itshiphu, ukususwa kwetshiphu ngokuzenzekelayo, njl., ephucula imveliso yabasebenzi.

(intloko yamandla ekhohlo)

2.3. Ukususwa kwe-chip kunye nokupholisa

Kukho izihambisi zetshiphu ezijikelezayo nezisicaba ezifakwe kumacala omabini ngaphantsi kwebhentshi yokusebenza, kwaye iitshiphusi zinokukhutshwa ngokuzenzekelayo kwisihambisi setshiphu ekugqibeleni ngokwamanqanaba amabini okujikeleza kunye neepleyiti zetyathanga ukuqonda imveliso ephucukileyo. Kukho impompo yokupholisa kwitanki yokupholisa yokuhambisa itshiphu, engasetyenziselwa ukupholisa kwangaphandle kwesixhobo ukuqinisekisa ukusebenza kokugrumba kunye nobomi benkonzo yentwana yokomba, kwaye isisipholisi sinokuphinda sisetyenziswe.

3.Inkqubo yolawulo lwamanani edijithali epheleleyo:

3.1.Ngomsebenzi wokuqhekeka kwetshiphu, ixesha lokuqhekeka kwetshiphu kunye nomjikelo wokuqhekeka kwetshiphu unokusetwa kujongano lomatshini womntu.

3.2.Ngomsebenzi wokuphakamisa isixhobo, ukuphakama kwesixhobo kunokusetwa kwi-interface yomatshini wendoda. Xa ukugrumba kufikelela kulo mphakamo, i-drill bit iphakanyiselwa ngokukhawuleza phezulu kwi-workpiece, kwaye ke iitshiphusi zilahlwa kude, kwaye zigqithise ngokukhawuleza kwindawo yokugaya kwaye ziguqulelwe ngokuzenzekelayo emsebenzini.

3.3.Ibhokisi yolawulo lokusebenza esembindini kunye neyunithi ephathwayo yamkele inkqubo yolawulo lwamanani kwaye ixhotyiswe ngojongano lwe-USB kunye nomboniso we-LCD wekristale engamanzi. Ukuze kuququzelelwe inkqubo, ukugcinwa, umboniso kunye nonxibelelwano, ujongano lokusebenza lunemisebenzi efana nencoko yababini yomatshini, imbuyekezo yempazamo, kunye ne-alamu ezenzekelayo.

3.4.Isixhobo sinomsebenzi wokujonga kwaye uphinde uhlolisise indawo yomngxuma ngaphambi kokucubungula, kwaye ukusebenza kulula kakhulu.

4. Ukuthambisa okuzenzekelayo

Isixhobo somatshini sokuchaneka kwesikhokelo somgca ngababini ngababini, izibini ezichanekileyo zebhola kunye nezinye iiperi ezichanekileyo eziphezulu zixhotyiswe ngeenkqubo zokuthambisa ezizenzekelayo. Ipompo yokuthambisa ngokuzenzekelayo ikhupha i-oyile yoxinzelelo, kwaye igumbi le-oyile ye-lubricator yobungakanani ingena kwioyile. Emva kokuba igumbi leoli lizaliswe ngeoli, xa uxinzelelo lwenkqubo luphakama ukuya kwi-1.4-1.75Mpa, ukutshintshwa koxinzelelo kwinkqubo ivaliwe, ipompo iyayeka, kwaye i-valve yokukhulula ikhupha ngexesha elifanayo. Xa uxinzelelo lwe-oyile kwindlela yehla ngaphantsi kwe-0.2Mpa, i-lubricator yobungakanani iqala ukuzalisa indawo yokuthambisa kwaye igqibe ukuzaliswa kweoli enye. Ngenxa yokunikezelwa kweoyile echanekileyo yomthamo we-oyile kunye nokufunyanwa koxinzelelo lwenkqubo, unikezelo lweoyile luthembekile, luqinisekisa ukuba kukho ifilimu yeoli kumphezulu wesibini ngasinye sekinematic, ukunciphisa ukungqubana kunye nokunxiba, kunye nokuthintela umonakalo isakhiwo sangaphakathi esibangelwa kukufudumala. , ukuqinisekisa ukuchaneka kunye nobomi besixhobo somatshini. Xa kuthelekiswa nesibini sesikhokelo sokutyibilika sikaloliwe, isibini sesikhokelo sikaloliwe esiqengqelekayo esisetyenziswe kwesi sixhobo somatshini sinothotho lweenzuzo:

①Uvakalelo lwentshukumo luphezulu, i-coefficient ye-friction ye-rolling guide rail incinci, kuphela i-0.0025 ~ 0.01, kwaye amandla okuqhuba ayancipha kakhulu, alingana ne-1/10 yoomatshini abaqhelekileyo.

② Umahluko phakathi kwengxabano eguqukayo kunye ne-static incinci kakhulu, kwaye ukusebenza okulandelayo kugqwesileyo, oko kukuthi, ixesha lekhefu phakathi komqondiso wokuqhuba kunye nesenzo soomatshini sifutshane kakhulu, esilungele ukuphucula isantya sokuphendula kunye novakalelo lwe inkqubo yolawulo lwamanani.

③Ilungele intshukumo yomgca enesantya esiphezulu, kwaye isantya sayo esikhawulezileyo simalunga namaxesha ali-10 aphezulu kunoololiwe besikhokelo sokutyibilika.

④ Inokuqonda intshukumo engenasikhewu kwaye iphucule ukuqina kwentshukumo yenkqubo yoomatshini.

⑤Iveliswe ngabavelisi abaqeqeshiweyo, inokuchaneka okuphezulu, ukuguquguquka okuhle kunye nokugcinwa lula.

5. Indawo yokusetyenziswa komatshini:

Ubonelelo lwamandla: isigaba sesithathu AC380V ± 10% , 50Hz ± 1 Ubushushu be-Ambient: 0 ° ~ 45 °

Ezintlanu, ezona parameters zobugcisa:

6. Iiparamitha zobugcisa

| Umzekelo | BOSM12010 | |

| Ubungakanani bobungakanani bomsebenzi wokusetyenzwa | Ubude × ububanzi × ubude (mm) | 12000×1000×1500 |

| Ubuninzi be-Cutter Diameter | 200mm | |

| Isondlo esiphezulu seGantry | Ububanzi (mm) | 1300 |

| ubungakanani bedesika esebenzayo | Ubude X Ububanzi (mm) | 12000*1000 |

|

Intloko yenkunzi yegusha ethe tye amandla intloko enye ezimbini

| Ubuninzi (2) | 2 |

| I-Spindle taper | BT50 | |

| Idayamitha yokomba (mm) | Φ2-Φ60 | |

| Ukucofa idayamitha (mm) | M3-M30 | |

| Isantya sokujikeleza (r/min) | 30-6000 | |

| Amandla e-Servo spindle motor (kw) | 37 | |

| Umgama wempumlo yokusonta ukusuka kumbindi wetafile (mm) | 150-650 | |

| Ukubetha kwasekhohlo nasekunene kwenkunzi yegusha enye (mm) | 500 | |

| Umgama phakathi kombindi wenkunzi yegusha kunye nendiza yetafile (mm) | 200-1700 | |

| Ukubetha phezulu naphantsi kwenkunzi yegusha (mm) | 1500 | |

| Ukuphindaphinda | 300mm*300mm | ±0.02 |

| Ubungakanani besixhobo somatshini | Ubude × ububanzi × ubude (mm) | ngokwemizobo |

| Ubunzima obupheleleyo (t) | (malunga.) 62 | |

Ezi parameters zingasentla ziyiparameters zoyilo lokuqala. Kuyilo lokwenyani, kunokubakho utshintsho ngokweemfuno zokusetyenzwa kwesixhobo sokusebenza kunye neemfuno zoyilo lwesixhobo somatshini, ukuze kuhlangatyezwane neemfuno zamacandelo omsebenzi wenkampani yakho.