Umatshini wokuDla iSitishi seFlange ezine

Iimpawu zoomatshini

Isikhululo esine-Flange ye-CNC yokugrumba kunye nothotho lomatshini wokungqusha isetyenziselwa ikakhulu ukusetyenzwa kweflange ejikelezayo, kwaye ingasetyenziselwa ukomba osebenzayo / ukugaya izixhobo zokusebenza ezinobunzima ngaphakathi koluhlu olusebenzayo olunje ngesiqingatha seshafu, iipleyiti ezisicaba, iiflange, iidiski kunye namakhonkco. / Ukucofa / ukubuyisela kwakhona / ukukrola kunye nezinye iinkqubo. Ngemingxuma kunye nemingxuma eyimfama inokugrunjwa kwiindawo eziphathekayo ezilula kunye nezixhobo ezidibeneyo. Isixhobo somatshini silawulwa ngedijithali ukuze kube lula ukusebenza. Unokufezekisa i-automation, ukuchaneka okuphezulu, iintlobo ezininzi, imveliso yobuninzi.

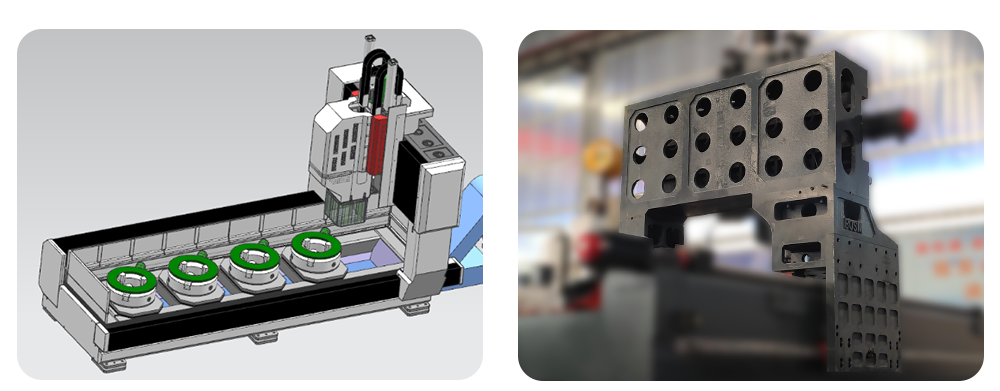

Ulwakhiwo lomatshini

Lo matshini ubukhulu becala unetafile yokusebenza, iiseti ezine zehydraulic ezinemihlathi ezizimelayo, igantry ehambayo, isali yokutyibilika eshukumayo, i-drilling kunye nentloko yamandla okusila, isixhobo sokuthambisa esizenzekelayo kunye nesixhobo sokukhusela, isixhobo sokupholisa esijikelezayo, a inkqubo yolawulo lwedijithali, kunye nenkqubo yombane. Ukwakhiwa njalo njalo. Ukuxhaswa kunye nokukhokela isikhokelo somgca wokuhamba kunye ne-screw drive echanekileyo, isixhobo somatshini sinokuchaneka kokumisa okuphezulu kunye nokuphindaphinda ukuchaneka kokubeka.

1.Itafile yokusebenza yebhedi:

Ibhedi yenziwe ngamalungu entsimbi. Igqitywe ngonyango lwesibini lobushushu. Inokuqina okuguquguqukayo kunye nokuzinzileyo kwaye ayikhubazeki. Itheyibhile yokusebenza isebenzisa iiseti ezine ze-500mm zemihlathi emine ezizinzisa i-hydraulic chucks ukuze zibambe ngokukhawuleza izixhobo zokusebenza. Izibini ezimbini ze-ultra-high-capacity linear rolling pairs zifakwe kumacala omabini ebhedi. Emva kokumiswa, iiseti ezimbini zokutshixwa okusuka kumazwe angaphandle koxinzelelo oluphezulu. I-clamp ingena ngokugqibeleleyo ngaphandle kokonakalisa isilayidi sikaloliwe. I-clamp yokuvula kunye nexesha lokuvala yimizuzwana ye-0.06 kuphela, enciphisa kakhulu ixesha lokucubungula. Inkqubo yokuqhuba isebenzisa i-bus absolute servo motor kunye nokuchaneka I-screw yebhola iqhuba i-gantry ukuya kwicala le-Y-axis. Iibholiti ezilungelelanisiweyo zisasazwa phantsi kwebhedi, enokuthi ilungelelanise ngokulula inqanaba letafile yokulala.

2.I-Mobile Gantry:

I-gantry ehambayo iphoswe ngentsimbi engwevu 250. Ukuphakama kwebhondi enzima yi-800mm ukunyusa amandla ayo. Izibini ezimbini zesikhokelo esine-super-high-capacity rolling linear zifakwe kwicala langaphambili le-gantry. Isilayidi esiluhlaza sisebenzisa isikrufu sebhola echanekileyo kunye ne-servo motor ukuhambisa intloko yesilayidi yamandla kwicala le-Y axis. Intloko yamandla okomba ifakwe kwisilayidi sentloko yamandla. Ukuhamba kwe-gantry kuqondwa yi-servo motor eqhuba i-screw mother yebhola ukujikeleza kwi-screw yebhola ngokudibanisa ngokuchanekileyo.

3.Isali yesilayidi ehambayo:

Isali yokutyibilika eshukumayo licandelo lolwakhiwo lwentsimbi echanekileyo. Isali yokutyibilika yandisiwe kwaye yandiswa ukwandisa umgama osembindini womzila kaloliwe. Iiseti ezimbini ze-Ultra-high-capacity rolling linear guide pairs kunye ne-precision ball screw pairs ziqhagamshelwe kwingalo echanekileyo ephezulu I-brake servo motor iqhuba intloko yamandla okuqhuba ukuba ihambe kwicala le-Z-axis, enokuqonda ngokukhawuleza phambili, ukuqhubela phambili kwezoshishino, ukubuyisela umva ngokukhawuleza, kunye nokumisa intloko yamandla. Ngokuqhawuka kwetshiphu ngokuzenzekelayo, ukususwa kwetshiphu, imisebenzi yokumisa ikhefu.

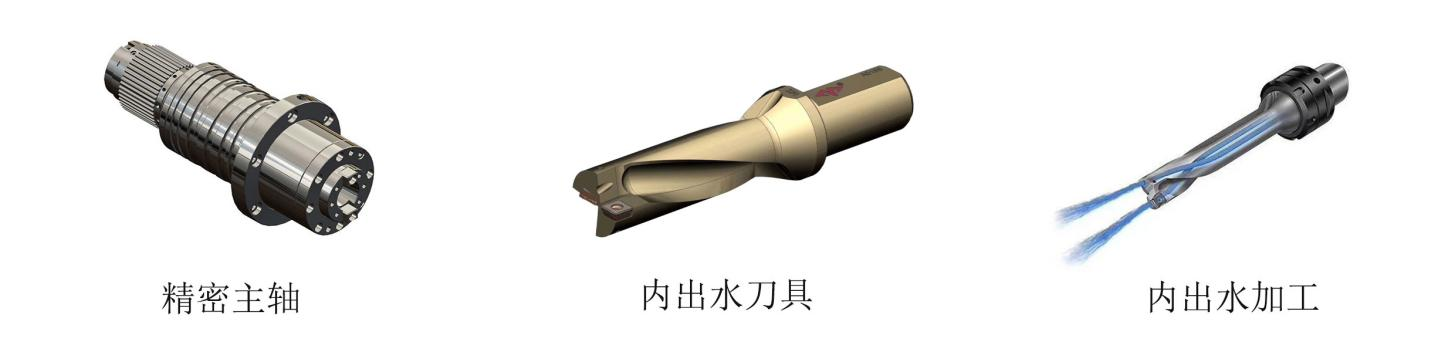

4.Intloko yamandla okomba:

Intloko yamandla okomba isebenzisa i-servo spindle motor. I-spindle ye-mechanical echanekileyo iqhutywe yi-deceleration yebhanti ye-synchronous ene-toothed ukwandisa i-torque. I-spindle isebenzisa umphambili wesithathu, emibini, kunye nomqolo ontlanu wokuqhagamshelwa kwe-angular yaseJapan ukufikelela kwisantya esingenanyathelo. Ukutshintshwa ngokukhawuleza kunye nokulula, ukutya kuqhutywa yi-servo motor kunye nebhola. Ii-axes ze-X kunye ne-Y zinokudibaniswa, kunye nolawulo lwe-loop oluvaliweyo oluvaliweyo lungasetyenziselwa ukufezekisa imisebenzi yokudibanisa kunye nesetyhula.

5. Flat chain oluzenzekelayo chip conveyor kunye nesixhobo sokupholisa esijikelezayo

Lo matshini uxhotyiswe ngetsheyini elisicaba elizenzekelayo lokuhambisa itshiphu kunye nomqokeleli wetshiphu. Isixhobo sokupholisa esijikelezayo sixhotyiswe ngesihluzo sephepha, esinempompo yokupholisa yangaphakathi yoxinzelelo oluphezulu kunye nompompo wokupholisa wangaphandle ophantsi wokupholisa ngaphakathi nangaphandle kwesixhobo.

5.1 Isixhobo sokuthambisa esizenzekelayo kunye nesixhobo sokukhusela:

Lo matshini uxhotyiswe ngesixhobo sokuthambisa esizenzekelayo se-volumetric saseTaiwan, esinokuthambisa ngokuzenzekelayo iileyili zesikhokelo, izikrufu ezihamba phambili kunye nezinye izibini ezihambayo, kwaye akukho angle efileyo yokuqinisekisa ubomi benkonzo yomatshini. I-X-axis kunye ne-Y-axis yesixhobo somatshini ixhotyiswe ngezixhobo zokukhusela ezinothuli, kunye nabalindi be-splash abangenamanzi bafakwe kwi-workbench.

6. CNCinkqubo yolawulo:

6.1. Ngomsebenzi wokuqhekeka kwetshiphu, ixesha lokuqhekeka kwetshiphu kunye nomjikelo wokuqhekeka kwetshiphu unokusetwa kujongano lomatshini womntu.

6.2. Ngomsebenzi wokuphakamisa isixhobo, ukuphakama kwesixhobo kunokusetwa kwi-interface yomatshini wendoda. Xa ubhobhoza kulo mphakamo, i-drill bit iphakanyiswe ngokukhawuleza ngaphezu kwendawo yokusebenza, kwaye ke i-chip iyatshitshiswa, kwaye emva koko idluliselwe ngokukhawuleza kwindawo yokugaya kwaye iguqulelwe ngokuzenzekelayo emsebenzini.

6.3. Ibhokisi yolawulo lokusebenza esembindini kunye neyunithi ephathwayo ithatha inkqubo yolawulo lwamanani, kwaye ixhotyiswe nge-USB interface kunye nomboniso weLCD. Ukuze kuququzelelwe inkqubo, ukugcinwa, umboniso kunye nonxibelelwano, ujongano lokusebenza lunemisebenzi efana nencoko yababini yomatshini, imbuyekezo yempazamo, kunye ne-alamu ezenzekelayo.

6.4. Isixhobo sinomsebenzi wokujonga kwangaphambili kunye nokujonga kwakhona indawo yomngxuma ngaphambi kokucubungula, kwaye ukusebenza kulula kakhulu.

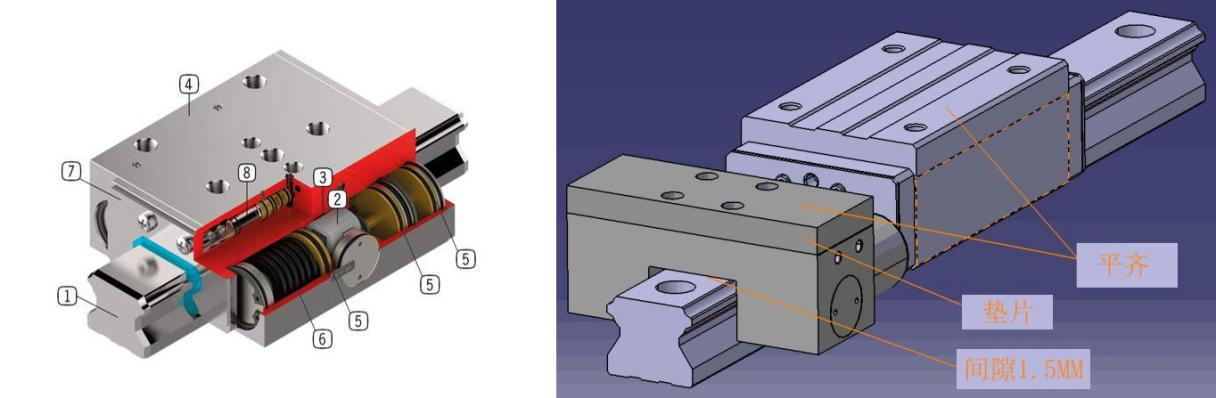

7.Ibamba likaloliwe:

I-clamp yenziwe ngumzimba oyintloko we-clamp, i-actuator, njl. Ngomgaqo-siseko wokwandiswa kwe-wedge block force, ivelisa amandla anamandla okubamba; ine-gantry esisigxina, indawo echanekileyo, i-anti-vibration kunye noMsebenzi wokuphucula ukuqina.

Inezi mpawu zilandelayo:

Ø 1) Ikhuselekile kwaye ithembekile, inamandla okubamba awomeleleyo, ibamba i-axis ye-XY engashukumiyo ngexesha lokomba kunye nokucofa ukucofa.

Ø 2) Amandla okubamba aphezulu kakhulu anyusa ubungqongqo be-axial feed kwaye anqande ukuxhathisa okubangelwa kukungcangcazela.

Ø 3) Ukuphendula ngokukhawuleza, ixesha lokuphendula lokuvula kunye nokuvala yimizuzwana ye-0.06 kuphela, enokukhusela isixhobo somatshini kunye nokwandisa ubomi be-screw lead.

Ø 4) Indawo ehlala ixesha elide, ene-nickel-plated, ukusebenza kakuhle kokuchasana nokurusa.

Ø 5) Uyilo lweNoveli ukunqanda impembelelo engqongqo xa uqiniswa.

Speification

| Umzekelo | BOSM-DS500 | Iyunithi | |

| Ubungakanani bobungakanani bomsebenzi omkhulu | Idayimitha yangaphandle | 50-500 | mm |

| Ubuphezulu bobude bomsebenzi | 300 | Kg | |

| Idayamitha yesiqingatha seshaft yokusebenzela | ≤200 | mm | |

| Ubude beshaft | I-700mm inokunyuswa ngokwesiseko | mm | |

| Ukutyeba kweworkpiece | ≤5 amaxesha e-drill diameter | mm | |

| Uhlobo lwenkunzi yegusha ethe nkqo yokomba intloko yamandla | QTY | 1 | IiPC |

| I-Spindle taper | BT40 | ||

| Drill idayamitha | Φ2-Φ36 | mm | |

| Ukucofa uluhlu | M6-M24 | ||

| Isantya se-spindle | 30-3000 | r/mm | |

| Servo spindle motor amandla | 15 | Kw | |

| Umgama ukusuka kumazantsi e-spindle ukuya kwitafile yokusebenza | 150-550mm±20 | mm | |

| Intshukumo yamva yentloko yamandla (X Axis) | MAX. uhambo | 2600 | mm |

| X Isantya se-axis | 0~8 | m/umz | |

| X Axis servo motor amandla | 2.4 | Kw | |

| Intshukumo yobude bomqadi oshukumayo (Y Axis) | MAX. uhambo | 500 | mm |

| Isantya se-Y Axis | 0~8 | m/umz | |

| Y Axis servo amandla motor | 2.4 | Kw | |

| Intshukumo yokutya okuthe nkqo (i-axis Z) | MAX. uhambo | 400 | mm |

| Isantya se-axis yeZ | 0~4 | m/umz | |

| Z Axis servo motor amandla | 1 × 2.4 ibhuleki | Kw | |

| Ukubeka ukuchaneka | 500x500 | ±0.03 | mm |

| Ukuchaneka kwesalathisi | 360 ° | ±0.001° | |

| Ubukhulu bomatshini | Ubude x ububanzi x ubude | 3600×1650×2300 | mm |

| Ubunzima bomatshini | 8.5 | T | |

Ukuhlolwa koMgangatho

Umatshini ngamnye ulinganiswe nge-laser interferometer evela kwinkampani yase-United Kingdom ye-RENISHAW, ehlola ngokuchanekileyo kwaye ihlawule iimpazamo ze-pitch, i-backlash, ukuchaneka kokumisa, kunye nokuphindaphinda ukuchaneka kokumisa ukuqinisekisa ukuguquguquka komatshini, ukuzinza kwe-static, kunye nokucubungula ukuchaneka. . Uvavanyo lwebha yebhola Umatshini ngamnye usebenzisa umvavanyi webar yebhola evela kwinkampani yaseBritani ye-RENISHAW ukulungisa isangqa sokwenyani ukuchaneka kunye ma.

ukuchaneka kwejiyometri ye-chine, kwaye wenze imifuniselo yokusika esetyhula ngaxeshanye ukuqinisekisa ukuchaneka komatshini we-3D kunye nokuchaneka kwesangqa.

Indawo yokusetyenziswa kwesixhobo somatshini

1.1 Izixhobo zokusingqongileyo iimfuno

Ukugcina iqondo elingaguqukiyo lobushushu be-ambient yinto eyimfuneko kumatshini ochanekileyo.

(1) Ubushushu obukhoyo be-ambient yi -10 ℃ ~ 35 ℃. Xa ubushushu be-ambient bungama-20 ℃, ukufuma kufuneka kube yi-40 ~ 75%.

(2) Ukuze kugcinwe ukuchaneka okumileyo kwesixhobo somatshini ngaphakathi koluhlu oluchaziweyo, elona qondo lobushushu lendawo lifuneka ukuba libe yi-15 ° C ukuya kuma-25 ° C kunye nomahluko wobushushu.

Akufunekanga idlule ± 2 ℃ / 24h.

1.2 Amandla ombane ombane: isigaba se-3, i-380V, ukuguquguquka kombane ngaphakathi kwe-± 10%, i-frequency supply frequency: 50HZ.

1.3 Ukuba i-voltage kwindawo yokusetyenziswa ayizinzile, isixhobo somatshini kufuneka sixhotyiswe umbane olawulwayo ukuze kuqinisekiswe ukusebenza okuqhelekileyo kwesixhobo somatshini.

1.4. Isixhobo somatshini kufuneka sibe nesiseko esithembekileyo: ucingo lokumisa lucingo lobhedu, ububanzi bocingo akufunekanga lube ngaphantsi kwe-10mm², kwaye ukuxhathisa komhlaba kungaphantsi kwe-4 ohms.

1.5 Ukuze kuqinisekiswe ukusebenza okuqhelekileyo kwesixhobo, ukuba umoya ocinezelweyo womthombo womoya uyasilela ukuhlangabezana neemfuno zomthombo womoya, iseti yezixhobo zokucoca umthombo womoya (i-dehumidification, degreasing, filtering) kufuneka yongezwe phambi kokuba umoya wokungena kumatshini.

1.6. Izixhobo kufuneka zigcinwe kude nelanga elithe ngqo, ukungcangcazela kunye nemithombo yokushisa, kwaye kude neejeneretha eziphezulu ze-frequency, oomatshini be-welding yombane, njl., ukwenzela ukuba ugweme ukusilela kokuvelisa umatshini okanye ukulahleka kokuchaneka komatshini.

Ngaphambi nasemva kweNkonzo

1)Ngaphambi kweNkonzo

Ngokufunda isicelo kunye nolwazi oluyimfuneko kubathengi emva koko impendulo kwiinjineli zethu, iqela le-Bossman Technical lijongene nonxibelelwano lobugcisa kunye nabathengi kunye nokuqulunqwa kwezisombululo, ukuncedisa umthengi ekukhetheni isisombululo esifanelekileyo somatshini kunye noomatshini abafanelekileyo.

2)Emva kweNkonzo

A.Umatshini onewaranti yonyaka omnye kwaye uhlawulwe ulondolozo lobomi bonke.

B.Ngexesha lewaranti yonyaka omnye emva kokuba umatshini efikile kwindawo ekuyiwa kuyo, iBOSSMAN iya kubonelela ngeenkonzo zokugcinwa kwasimahla kunye nexesha elifanelekileyo kwiimpazamo ezahlukeneyo ezingenziwanga ngabantu kumatshini, kwaye zibuyisele ngexesha elifanelekileyo zonke iintlobo zomonakalo owenziwe ngumntu simahla. yentlawulo . Ukusilela okwenzeka kwixesha lewaranti kuya kulungiswa ngeentlawulo ezifanelekileyo.

Inkxaso ye-C.Technical kwiiyure ezingama-24 kwi-intanethi, i-TM, i-Skype, i-E-mail, ukusombulula imibuzo ehambelanayo ngexesha. ukuba ayinasombululo, iBOSSMAN iya kulungiselela kwangoko ukuba injineli yasemva kokuthengisa ifike kwindawo ukuze ilungiswe, umthengi ufuna ukuhlawulela iVISA, amatikiti eenqwelomoya kunye nendawo yokuhlala.

Isiza soMthengi