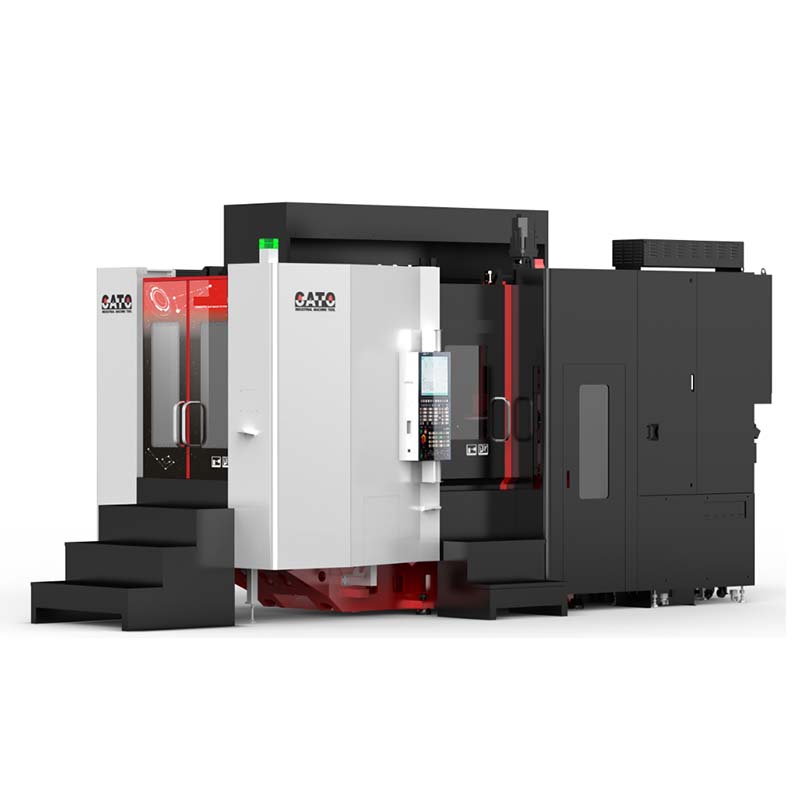

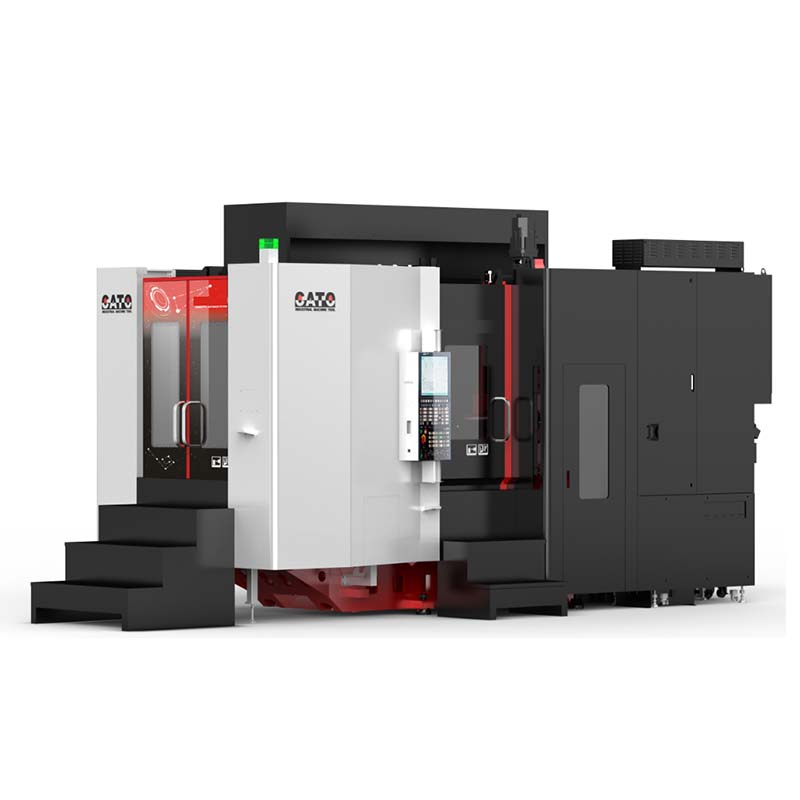

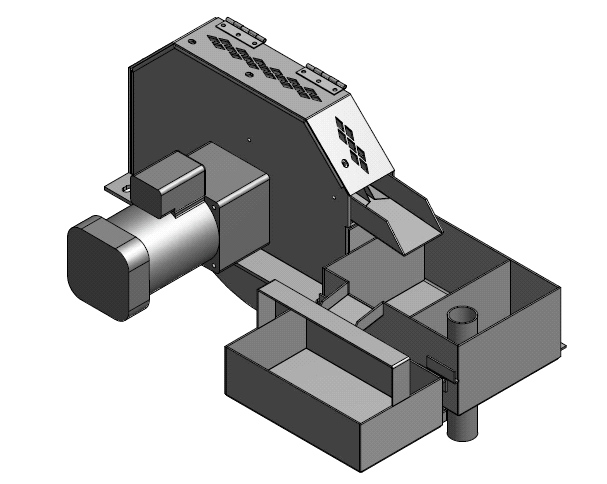

I-5-axis yeCNC eHorizontal Machining Centre enePallets ezimbini CP800

1.Iimpawu

Isantya esiphezulu, ukusebenza okuphezulu kunye nokuchaneka okuthe tyaba okuthe tyaba kwiziko lomatshini le-CP800T2 eliphuhliswe yiNkampani ye-CATO lineempawu zobungqongqo obuphezulu, ukuchaneka okuphezulu kunye nokusebenza kakuhle komatshini. Isiseko esisodwa siyamkelwa, kwaye i-T yoyilo lwesakhiwo esilungileyo somgangatho ophezulu kunye nomgangatho ophantsi we-rails iqinisekisa ukuqina okuphezulu kwesixhobo somatshini; umatshini wonke udlulisa uhlalutyo lwezinto ezinomda ukuze kuqinisekiswe ukuba isixhobo somatshini asingcangcazeli phantsi kwentshukumo enesantya esiphezulu, kwaye siqinisekisa okona kusebenza ixesha elide kuzinzo kumatshini wonke.

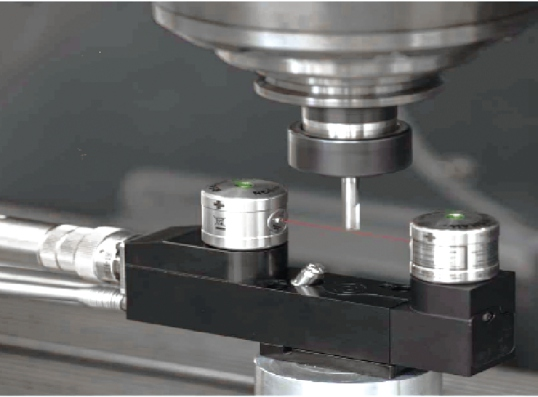

Ngokwamkela itekhnoloji ephezulu yesiphelo esinje ngesantya esiphezulu sobuchwephesha bokujikeleza, itekhnoloji yesantya esiphezulu sokutya, itekhnoloji yokutshintsha isixhobo esinesantya esiphezulu, kunye nesantya esiphezulu senkqubo yeCNC yetekhnoloji, ixesha lokucubungula lifinyeziwe kakhulu, ukusebenza kakuhle kuyaphuculwa, kunye neentlobo ezahlukeneyo. iimfuno zemveliso ziyahlangatyezwa. Ukufuduka ngokukhawuleza kwe-axis emithathu yi-60 M / min, kunye ne-speed-speed and high-torque electric spindle kunciphisa ukukhawuleza kunye nexesha lokunciphisa i-spindle. Ezi zalathi zinciphisa kakhulu ixesha lokungaqhubeki kunye nokuphucula ukusebenza kakuhle; i-screw / isihlalo esiphetheyo / i-spindle / i-DD i-swing intloko ithatha inkqubo yokulawula ubushushu, Isiqinisekiso se-thermal balance balance of the equipment, kwaye siphucule kakhulu ukuchaneka kunye nokuzinza kwezixhobo.

Ukwamkela inkqubo ye-Siemens 840D, i-19-intshi enkulu ye-LCD yokubonisa, umboniso oguqukayo wegraphic wesixhobo somzobo, umboniso wesilumkiso okrelekrele, ukuzixilonga kunye neminye imisebenzi yenza ukusetyenziswa kunye nokugcinwa kwesixhobo somatshini kube lula kwaye ngokukhawuleza; indlela yonxibelelwano yebhasi yesantya esiphezulu iphucula kakhulu ukusetyenzwa kwedatha yenkqubo ye-CNC Ukukwazi kunye nokulawula ukusebenza kuququzelela ukuhanjiswa okukhawulezayo nangokufanelekileyo kunye nokuqhutyelwa kwe-intanethi kweenkqubo zomthamo omkhulu.

2.Iparamitha

| Into | Iyunithi | CP800T2 | |

| Ukuhamba | Ukuhamba kwe-X/Y/Z umgca ohamba phambili | mm | 800 x 800 x 750 |

| Ukuhamba kwe-B-axis | ° | -30 ~ 120 | |

| Uhambo lwe-C-axis | ° | 360 | |

| Umgama ukusuka kumbindi wokusonta ukuya kumphezulu wetafile (i-B-axis 90 degrees horizontal) | mm | 160~910 | |

| Umgama ukusuka kwisiphelo sesiphelo sobuso ukuya kumphezulu wetafile (i-B-axis 0 degree degree nkqo) | mm | -83~667 | |

| Umgama ukusuka kwisiphelo sobuso be spindle ukuya kumbindi wetafile yokusebenza (i-B-axis 90 degrees horizontal) | mm | -135 ~ 665 | |

| Umgama ukusuka kumbindi we-spindle ukuya kwiziko letafile (i-B-axis 0 ° nkqo) | mm | 108~908 | |

| Uluhlu oluphezulu lokuqhuba | mm | Φ 720 x 910 | |

| Ukutya kwe-3 axis | X/Y/Z i-axis ihamba ngokukhawuleza | m/umz | 60/60/60 |

| Ukunciphisa izinga lokutya | mm/min | 0-24000 | |

| Itafile ejikelezayo (Umgca we-C) | Itafile ejikelezayo | iipcs | 2 |

| Idayamitha yediski | mm | 500*500 | |

| umthwalo ovumelekileyo | Kg | 500 | |

| isantya esiphezulu sokujikeleza | Rpm | 40 | |

| Ukuma/Ukuphinda ukuchaneka | arc.sec | 15/10 | |

| Umgca we-B | Ubuninzi besantya sokujikeleza | Rpm | 60 |

| Ukuma/Ukuphinda ukuchaneka | arc.sec | 8/4 | |

| I-spindle | Ukucaciswa kwespindle (ufakelo lwedayamitha/indlela yothumelo) | mm | 190 / Yakhelwe ngaphakathi |

| I-Spindle taper | m/umz | A63 | |

| Max. Isantya se-spindle | mm | 18000 | |

| Spindle Motor Power | Kw | 30/35 | |

| Spindle Motor Torque | Nm | 72/85 | |

| Isixhobo | Umthamo wemagazini yesixhobo |

| 40 T |

| Ixesha lokutshintsha izixhobo (TT) | s | 7 | |

| Ubuninzi bedayamitha yesixhobo (Isixhobo esigcweleyo / Isixhobo esisecaleni esingenanto esisecaleni) | mm | 80/150 | |

| Max. Ubude besixhobo | mm | 450 | |

| Max. Ubunzima besixhobo | Kg | 8 | |

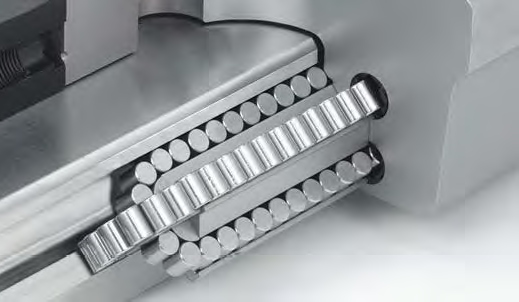

| Isikhokelo | Isikhokelo se-X-axis (ubungakanani/inani lezilayidi) |

| 45/2 (Irola) |

| Isikhokelo se-Y-axis (ubukhulu/inani lezilayidi) |

| 45/3 (Irola) | |

| Isikhokelo se-Z-axis (ubungakanani/inani lezilayidi) |

| 45/2 (Irola) | |

| Ntathu ekseni usulelo | X-axis lead screw | N | 2R 40 x 20 |

| I-Y-axis lead screw | N | 2R 40 x 20 | |

| Z-axis lead screw | N | 2R 40 x 20 | |

| Ukuchaneka kwe-axis ezintathu | Ukubeka ukuchaneka | mm | 0.005 / 300 |

| Phinda ukuchaneka kokubeka | mm | 0.003 / 300 | |

| Inkqubo yokuthambisa | Umthamo weyunithi yokuthambisa | L | 0.7 |

| Uhlobo lokuthambisa |

| Igrisi yokuthambisa | |

| Abanye | Imfuno yomoya | Kg/cm2 | ≥ 6 |

| Ukuhamba komthombo womoya | mm3/min | ≥ 0.5 | |

| Ubunzima | T | 11 | |

3.Yima ubumbeko

| NO. | Igama |

| 1 | Siemens 840D① Umphezulu ogqwethekileyo;②Ipakethe yenkqubo yokugaya i-axis emihlanu; ③ Ikhadi le-axis ezintlanu; ④ Thintela i-B-axis ekuweni; ⑤I-USB kunye ne-Ethernet yokudluliselwa kwedatha |

| 2 | Umsebenzi wokucofa ngaxeshanye |

| 3 | X/Y/Z isikrufu inkqubo yokupholisa emngxunyeni |

| 4 | Inkqubo yokulawula ubushushu be-spindle/B-axis |

| 5 | Ukhuselo lomthwalo ogqithisiweyo we-spindle |

| 6 | APC Double Exchange Workbench |

| 7 | I-B/C i-axis hydraulic brake system |

| 8 | Iphepha elifakwe ngokupheleleyo lesinyithi |

| 9 | Inkqubo yokutshixa iNcango yoKhuseleko |

| 10 | Isixhobo semagazini umnyango oluzenzekelayo |

| 11 | Inkqubo yokuthambisa igrisi ezenzekelayo |

| 12 | Ukukhanya kokukhanya komsebenzi we-LED |

| 13 | Ukusika izikrufu kumacala omabini |

| 14 | Inkqubo yokususa i-drum scraper |

| 15 | Inkqubo yokutshiza ejikelezileyo |

| 16 | inkqubo yokupholisa |

| 17 | I-CTS (2MPA) |

| 18 | Izixhobo eziqhelekileyo kunye neebhokisi zezixhobo |

| Izixhobo eziqhelekileyo kunye neebhokisi zezixhobo |