Umbindi weLathe ye-Axle

Uhlalutyo lwetekhnoloji ye-axle yemoto

Iasi yemoto

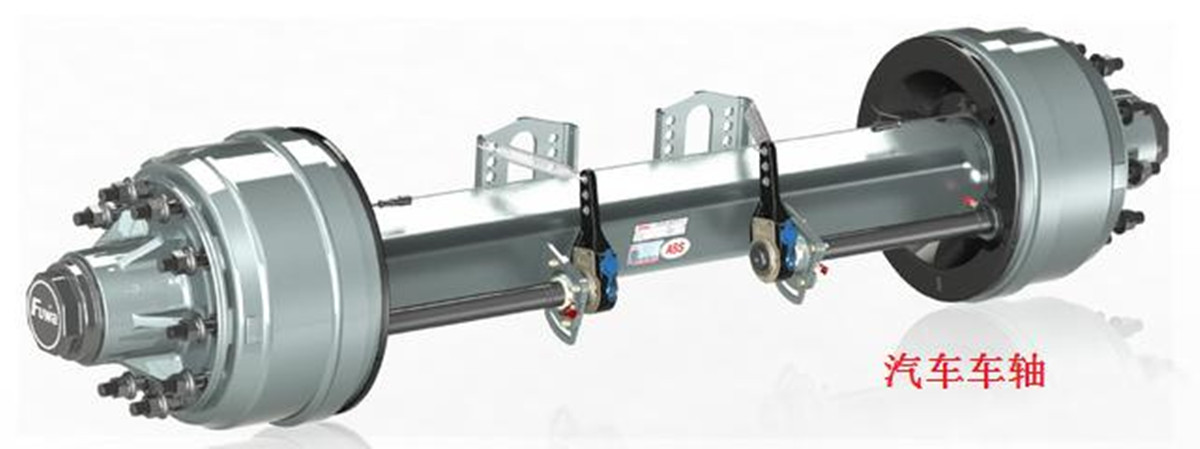

Ii-axles ezinamavili kumacala omabini e-undercarriage (isakhelo) zibizwa ngokudibeneyo njengee-axles zemoto, kwaye ii-axles ezinamandla okuqhuba zibizwa ngokuba zii-axles. Umahluko omkhulu phakathi kwezi zibini kukuba kukho i-drive embindini we-axle (i-axle). Kweli phepha, i-axle yemoto eneyunithi yokuqhuba ibizwa ngokuba yi-axle yemoto, kwaye isithuthi ngaphandle kwe-drive sibizwa ngokuba yi-axle yemoto ukubonisa umahluko.

Ngokunyuka kwemfuno yezothutho kunye nokuhamba, ukongama kwee-axles zemoto, ngakumbi iitreyila kunye ne-semi-trailer, kuthutho lobuchwephesha kunye nemisebenzi ekhethekileyo iya icaca ngakumbi, kwaye imfuno yentengiso inyuke kakhulu.

Olu hlaziyo lwetekhnoloji inkqubo yomatshini we-axle, ithemba lokunceda abathengi ukuba bakhethe umatshini we-CNC ofanelekileyo.

Ukuhlelwa kwe-asi yemoto:

Iindidi ze-axles zihluke ngokohlobo lwe-brake, kwaye zihlulwe zibe: i-disc brake axles, i-drum brake axles, njl.

Ngokobukhulu besakhiwo sobubanzi be-shaft, ihlukaniswe ibe: i-axle yaseMelika, i-axle yaseJamani; njl.

Ngokwemilo kunye nesakhiwo, yahlulwe ibe:

iyonke: i-asi yetyhubhu esomeleleyo, i-asi yesikwere setyhubhu enomngxuma, i-asi engqukuva engqukuva;

umzimba owahlulwe: intloko ye-shaft + umngxuma we-tube ye-shaft welding.

Ukususela kumxholo wokucubungula we-axle, i-axles eqinile kunye ne-hollow inxulumene nokukhethwa kwezixhobo zokusebenza.

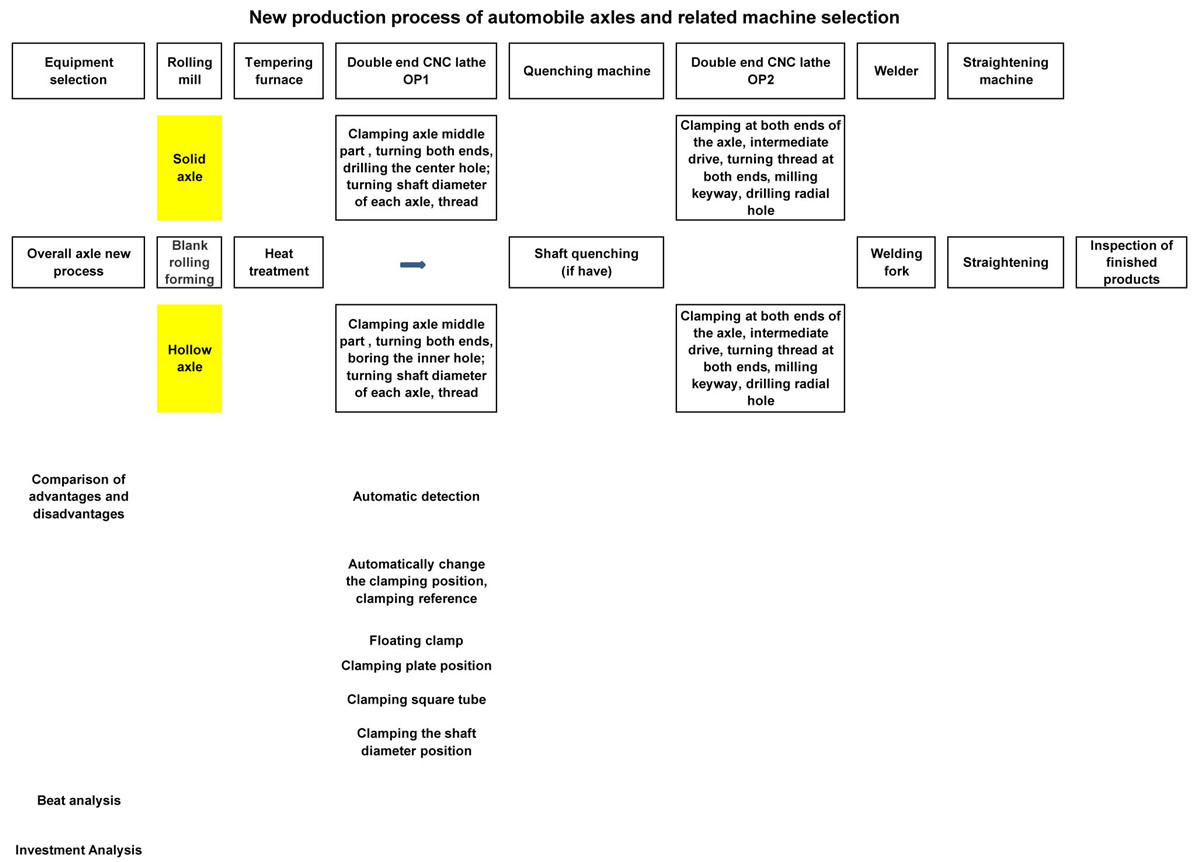

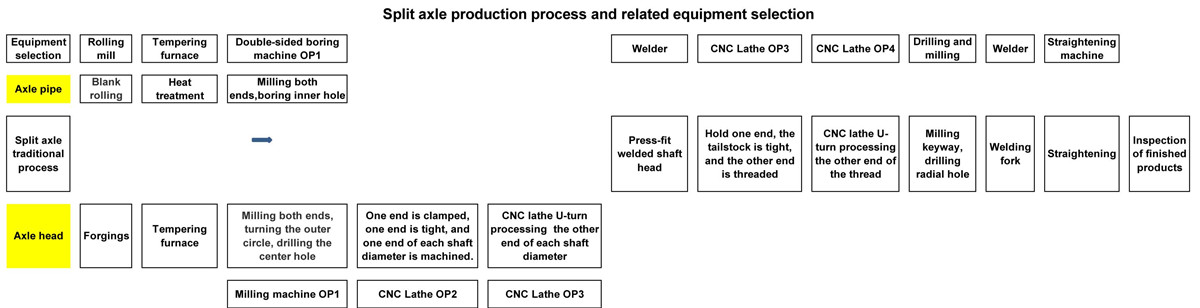

Oku kulandelayo kuhlalutyo lwenkqubo yokuvelisa i-axle yonke (ikwahlulwe ibe yingqimba kunye ne-hollow; ityhubhu yesikwere kunye netyhubhu ejikelezileyo), kunye ne-axle yokwahlula (intloko ye-shaft eqinileyo kunye ne-hollow + i-hollow shaft tube welding), ngokukodwa, inkqubo yokucoca. ihlalutywa ukukhetha ngcono umatshini ofanelekileyo ngakumbi.

Inkqubo yokuvelisa kunye nomatshini wee-asi zemoto:

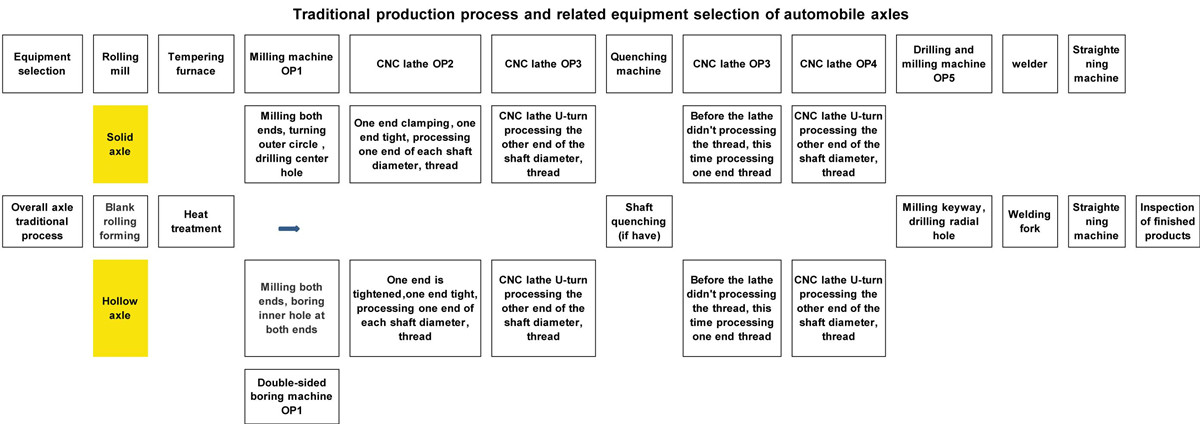

1. Inkqubo yemveli yemveliso ye-asi iyonke:

Ukusuka kwinkqubo yokuvelisa i-axle engentla, ubuncinane iintlobo ezintathu zezixhobo zoomatshini ziyafuneka ukuze kugqitywe umatshini: umatshini wokungqusha okanye umatshini odikayo wamacala amabini, i-CNC lathe, umatshini wokugaya kunye nowokusila, kunye ne-CNC lathe kufuneka ijikwe (abanye abathengi ikhethwe kabini-intloko CNC lathe). Ngokumalunga nokucutshungulwa kwentambo, ukuba i-shaft diameter icinyiwe, icutshungulwa emva kokucima; ukuba akukho kucinywa, icutshungulwa kwi-OP2 kunye ne-OP3, kwaye i-OP4 kunye ne-OP5 yokulandelelanisa izixhobo zomatshini azifakwanga.

Ukusuka kwinkqubo entsha yokuvelisa, umatshini wokungqusha osetyenziselwa umatshini (i-axle eqinileyo) okanye umatshini wokudikayo omacala omabini (i-asi egobileyo) kunye ne-CNC lathe, i-OP1 yokusila yemveli, i-OP2, i-OP3 yokujika ulandelelwano, kunye ne-OP5 yokomba kunye nokusila Inokutshintshwa. ngesiphelo kabini CNC lathe OP1.

Kwii-axles eziqinileyo apho i-shaft ye-diameter ayifuni ukucinywa, yonke imixholo yomatshini inokugqityezelwa kwisethingi enye, kubandakanywa i-grooves engundoqo yokugaya kunye ne-drilling imingxuma ye-radial. Kwii-axles ezingenanto apho i-shaft i-diameter ayifuni ukucinywa, umgangatho wokuguqula ukuguqulwa ngokuzenzekelayo unokuphunyezwa kwisixhobo somatshini, kwaye umxholo womatshini unokugqitywa ngesixhobo esinye somatshini.

Khetha i-axle enesiphelo esiphindwe kabini i-axle ekhethekileyo ye-CNC yokutshiza i-axles inciphisa kakhulu indlela yokwenza, kwaye uhlobo kunye nobuninzi bezixhobo zomatshini ezikhethiweyo nazo ziya kuncitshiswa.

3.Ukwahlula inkqubo yokuvelisa i-asi:

Ukususela kule nkqubo ingentla, izixhobo zokusebenza zetyhubhu ye-axle ngaphambi kwe-welding nazo zingakhethwa njenge-lathe ye-CNC ephindwe kabini. Ukucutshungulwa kwe-axle emva kwe-welding, i-lathe ye-CNC ekhethekileyo yee-axles eziphela kabini kufuneka ibe yinto yokuqala: ukulungiswa kwangaxeshanye kuzo zombini iziphelo, ukusebenza kakuhle okuphezulu kunye nokuchaneka kakuhle komatshini. Ukuba indlela yesitshixo kunye nomngxuma we-radial kuzo zombini iziphelo ze-axle kufuneka zenziwe ngoomatshini, umatshini unokuxhotyiswa ngesibambi sesixhobo samandla ukucubungula indlela engundoqo elandelayo kunye nomngxuma weradial kunye.

4.Inzuzo kunye nenqaku lomatshini omtsha wokukhetha inkqubo:

I-1) Ugxininiso lwenkqubo, ukunciphisa amaxesha e-workpiece clamping, ukunciphisa ixesha lokuncedisa i-processing, usebenzisa iteknoloji yokucubungula ngexesha elinye kuzo zombini iziphelo, ukusebenza kakuhle kwemveliso kuphuculwe kakhulu.

I-2) I-clamping yexesha elinye, ukuqhutyelwa kwangaxeshanye kuzo zombini iziphelo kuphucula ukuchaneka kwe-machining kunye ne-coaxiality ye-axle.

3) Nciphisa inkqubo yokuvelisa, ukunciphisa ukuthengiswa kweengxenye kwindawo yokuvelisa, ukuphucula ukusebenza kakuhle kokusetyenziswa kwendawo, kunye nokunceda ukuphucula umbutho kunye nolawulo lwemveliso.

I-4) Ngenxa yokusetyenziswa kwezixhobo zokusebenza eziphezulu, inokuxhotyiswa kunye nokulayishwa kwezixhobo kunye nezixhobo zokugcina ukuphumeza imveliso ezenzekelayo ngokupheleleyo kunye nokunciphisa iindleko zabasebenzi.

I-5) I-workpiece igxininiswe kwindawo ephakathi, i-clamping inokwethenjelwa, kwaye i-torque efunekayo yokusikwa kwesixhobo somatshini yanele, kwaye inani elikhulu lokujika linokwenziwa.

I-6) Isixhobo somatshini sinokuxhotyiswa ngesixhobo sokufumanisa ngokuzenzekelayo, ngakumbi kwi-axle engenanto, enokuqinisekisa ubukhulu obufanayo be-axle emva komatshini.

7) Kwii-asi ezivulekileyo, xa imingxuma yangaphakathi kwiziphelo zombini ze-OP1 yokulandelelana igqityiwe, umthengi wendabuko uya kusebenzisa isiphelo esinye ukuphakamisa i-clamp kunye nesinye isiphelo sokusebenzisa i-tailstock ukuqinisa i-workpiece yokujika, kodwa ubukhulu umngxuma ongaphakathi wahlukile. Kumngxuma wangaphakathi omncinci, ukuqina kokuqina akwanelanga, i-torque ephezulu yokuqina akwanelanga, kwaye ukusika okusebenzayo akunakugqitywa.

Kwi-lathe yobuso obuphindwe kabini, i-axle evulekileyo, xa imingxuma yangaphakathi kwiziphelo zombini zesithuthi igqityiwe, umatshini utshintsha ngokuzenzekelayo imo yokudibanisa: iziphelo ezibini zisetyenziselwa ukuqinisa i-workpiece, kwaye i-drive ephakathi idada kwindawo yokusebenza. ukuhambisa itorque.

8) I-headstock ene-built-in hydraulic clamping workpiece ingahanjiswa kwicala lika-Z lomatshini. Umthengi unokubamba isikhundla kwityhubhu yesikwere esiphakathi (ityhubhu ejikelezileyo), indawo yeplate esezantsi kunye nendawo ye-shaft diameter ye-axle njengoko kufuneka.

5. Isiphelo:

Ukujonga le meko ingentla, ukusetyenziswa kwe-lathes ye-CNC ephindwe kabini kumatshini we-axles yemoto ineenzuzo ezibalulekileyo kwiinkqubo zemveli. Ithekhnoloji yokuvelisa ephuculweyo enokuthi ithathe indawo yezixhobo zemveli zoomatshini ngokwenkqubo yokuvelisa kunye nokwakhiwa komatshini.

Icandelo eliphakathi le

I-6.Ityala lomthengi we-Axle

Special Double-end Axle CNC lathe Intshayelelo

Uluhlu lokusetyenzwa kwe-asi: ∮50-200mm, □50-150mm, ubude bokulungisa: 1000-2800mm

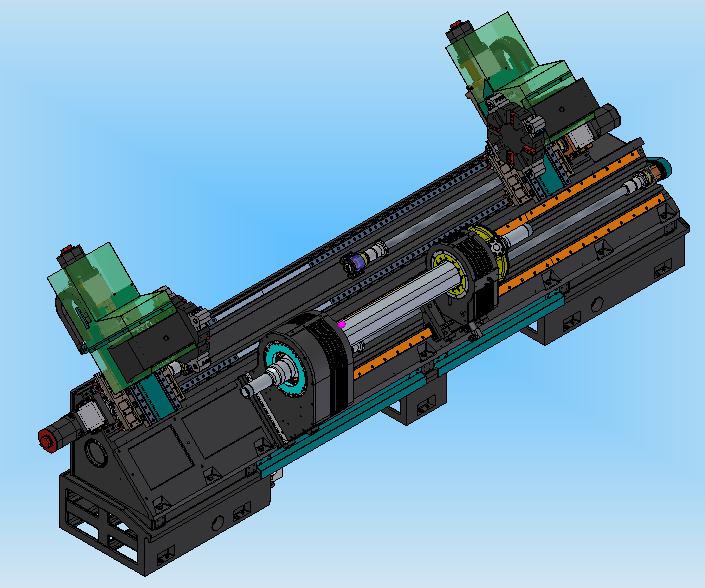

Ubume bomatshini kunye nentshayelelo yokusebenza

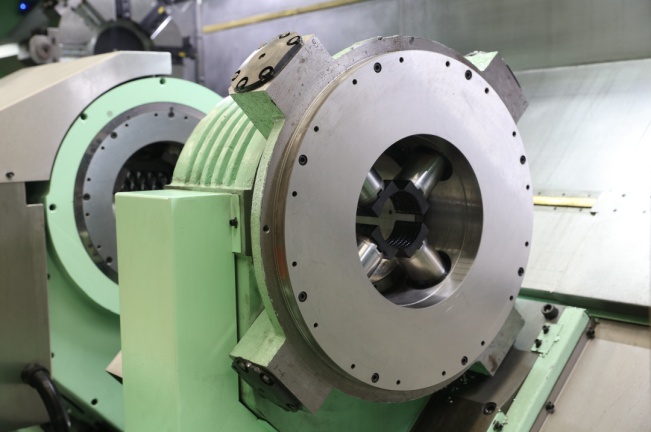

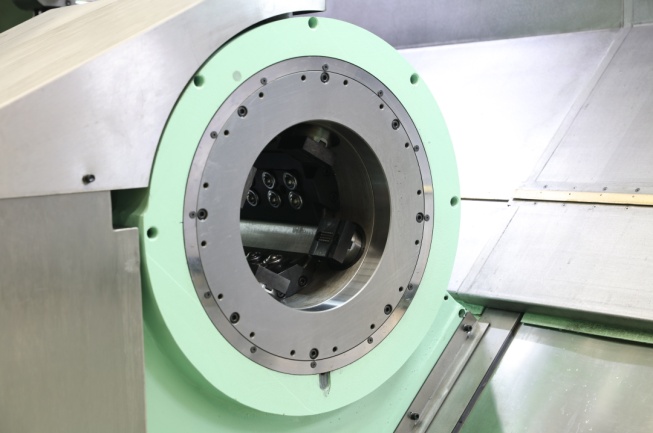

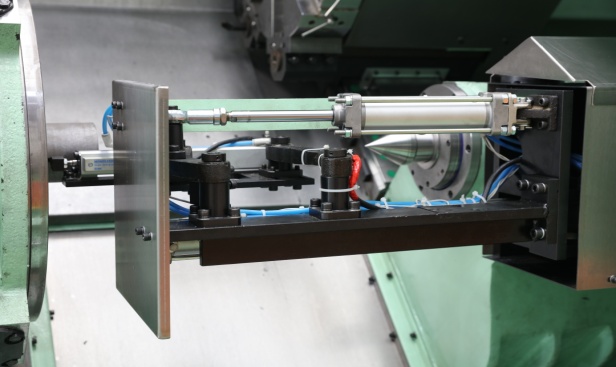

Isixhobo somatshini sithatha i-45 ° ye-slant bed layout, enokuqina okulungileyo kunye nokukhupha i-chip elula. I-headstock ene-intermediate drive clamping function icwangciswe embindini webhedi, kwaye izixhobo ezimbini zezixhobo zicwangciswe kumacala omabini ebhokisi yokuphotha. Ubude obuncinci bokubambelela kumatshini yi-1200mm kunye nobude obuphezulu be-machining yi-2800mm. Isikhokelo sokuqengqeleka siyamkelwa, kwaye i-servo feed shaft nganye ithatha i-screw ye-high-mute yebhola, kunye ne-elastic coupling idibaniswe ngokuthe ngqo, kwaye ingxolo iphantsi, ukuchaneka kokumisa kunye nokuchaneka okuphindaphindiweyo kuphezulu.

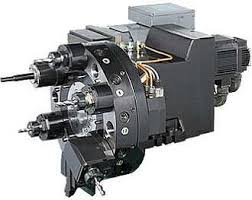

■ Umatshini uxhotyiswe ngenkqubo yokulawula yamajelo amabini. Abaphathi bezixhobo ezibini banokudityaniswa kwi-spindle ngexesha elinye okanye ngokwahlukileyo ukugqiba ngaxeshanye okanye ukucwangciswa komatshini kwiziphelo ezimbini zenxalenye.

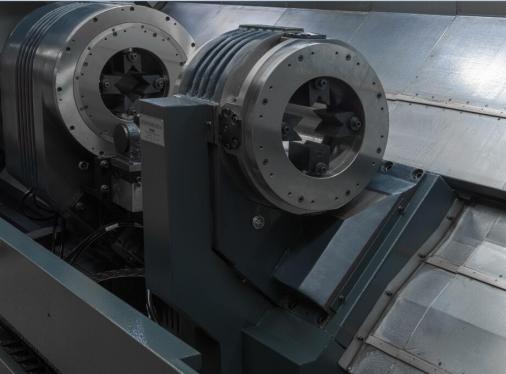

■ Umatshini uxhotyiswe ngeentloko ezimbini. I-headstock eyintloko igxininiswe phakathi kwebhedi, kwaye i-servo motor inika amandla kwi-shaft ephambili ngebhanti enamazinyo. Ibhokisi ye-sub-spindle ifakwe kwisikhokelo esisezantsi sikaloliwe wesixhobo somatshini, i-coaxial kunye nebhokisi yokuphotha ephambili, kwaye inokuhanjiswa nge-axially yi-servo motor ukuququzelela ukulayishwa kunye nokukhulula iinxalenye, kwaye kulungele ukuhlengahlengisa i-clamping eyahlukeneyo. izikhundla. Xa machining iindawo, sub-spindle base itshixiwe kumatshini kaloliwe. Ukuchaneka kwe-coaxial ye-headstocks ezimbini ziqinisekiswa yinkqubo yokuvelisa, okukhokelela kwiqondo eliphezulu lokugxilwa kweendawo ezinomatshini.

■ I-Headstock idibanisa inkqubo yokuphotha, i-fixture kunye nenkqubo yokusabalalisa i-oyile, kwaye inesakhiwo esincinci kunye nokusebenza okuthembekileyo. I-diameter ethile yokudibanisa kunye nobubanzi be-headstock inqunywe ngamalungu e-axle yomthengi.

Intloko yentloko iyancipha ngamanqanaba amabini ebhanti kunye negiya, okwenza ukuba i-spindle ikhuphe i-torque enkulu. I-clamp ifakwe kwisiphelo sasekhohlo sentloko yentloko kunye nesiphelo sasekunene se-sub-headstock ngokulandelelana ukuqaphela ukuxinzelela kwamalungu. Xa i-headstock eyintloko iqhuba iindawo ukuba zijikeleze, i-sub-headstock clamp clamping parts ijikeleza kunye nentloko yentloko.

Isixhobo sixhotyiswe ngeesilinda ezintathu zeradial (iisilinda ezine radial ukuba zombini imathiriyeli engqukuva kunye neskwere imathiriyeli ibambekile), ipiston iphinda ibuyiswe luxinzelelo lwehydraulic, kwaye iinzipho zifakwe ekupheleni kwepiston ukuqaphela iself-. ukubekwa kwamalungu. Ukuqhwesha. Kuyakhawuleza kwaye kulula ukutshintsha iinzipho xa utshintsha amalungu. I-clamping force ihlengahlengiswa yi-hydraulic system hydraulic pressure. Xa inxalenye yomatshini, i-clamp ijikeleza kunye ne-shaft engundoqo, kwaye inkqubo yokusabalalisa ioli inikezela ioli kwi-clamp, ukuze i-clamp ibe namandla okwaneleyo okubamba ngexesha lokujikeleza. I-clamp ineenzuzo ze-clamping force enkulu kunye ne-claw stroke enkulu.

■ Ukuze kulungiswe ingxaki yobunzima bodonga olufanayo emva komatshini we-asi onomngxuma womthengi, umatshini unokuxhotyiswa ngesixhobo sokuhlola i-workpiece ezenzekelayo. Emva kokuba i-axle clamping igqityiwe, i-workpiece ibona ngokuzenzekelayo ukuba i-probe iyanda kwaye ilinganisa isikhundla somsebenzi; emva kokuba umlinganiselo ugqityiwe, isixhobo sibuyela kwindawo evaliweyo.

Kwiinkqubo ezahlukeneyo zomatshini wee-asi ezingenanto, ukuba indawo yokuthwala isetyenziswa njengesalathiso sokucinezela, ulwakhiwo lomatshini olunokuqina okuzenzekelayo kunye nokudibanisa kunokukhethwa, kwaye i-tailstock enokucwangciswa ibonelelwa kumacala omabini eentloko eziphambili kunye nezincedisayo ukuhlangabezana ne iimfuno zomatshini omnye. Kulindeleke ukuba kugqitywe ukusetyenzwa kwamanyathelo amabini ngexesha. Kwangaxeshanye, yenza ukuba iindawo zokulayisha ngokuzenzekelayo kunye nokothula zibe nokukhetha okungaphezulu nangcono.

■Izibambi zesixhobo ezisekhohlo nasekunene zinokuxhotyiswa ngeziphatho zezixhobo eziqhelekileyo ezijikelezayo okanye ii-turrets zamandla. Zinemisebenzi yokomba kunye nokusila, enokuthi igqibe ukugrumba kunye nokugaya iindawo eziphambili.

■Isixhobo somatshini sivalwe ngokupheleleyo kwaye sixhotyiswe ngesixhobo sokuthambisa esizisebenzelayo kunye nesixhobo sokuzisusa setshiphu (ngaphambili). Inokusebenza kakuhle kokukhusela, inkangeleko entle, ukusebenza lula kunye nokugcinwa okufanelekileyo.

■ Iinkcukacha zoomatshini kunye nolungelelwaniso zimiselwa ngokweemfuno ze-asi kunye neemfuno zomthengi, kwaye aziyi kuphinda-phindwa apha.

Enkosi ngosinaka ixehsa lakho!