Umatshini we-lathe oqhelekileyoluhlobo lomatshini welathe wemveli ngaphandle kolawulo kodwa manual. Inoluhlu olubanzi lokusika kwaye lunokuqhuba imingxuma yangaphakathi, izangqa zangaphandle, ubuso bokuphela, indawo edibeneyo, i-chamfering, i-grooving, imicu kunye neendawo ezahlukeneyo ze-arc. Iileyile eziqhelekileyo lolona hlobo lusetyenziswa kakhulu koomatshini beleyitha, ababalelwa malunga ne-65% yenani lilonke lomatshini weleyile. Zibizwa ngokuba ziileyile ezithe tyaba ngenxa yokuba iintambo zazo zokusonta zibekwe ngokuthe tye.

Imisebenzi:

1. Ukujika kombhobho wangaphandle, ukujika kwekhowuni, ukujika komphezulu ogobileyo, ukujika komngxuma ongaphakathi, ukujika kobuso ekupheleni, i-chamfering kunye nokunye ukwenza;

2. Intambo ye-Metric, i-inch thread, intambo yemodyuli, i-pitch thread cutting;

3. Ukudubula kunye nokujika kwetaper ende;

4. Ukugrumba, ukukruqula, ukugqogqa kunye nokugrumba;

5. Ukujika kwesandla sasekhohlo kunye nokujika kwesandla sasekunene;

6. Nditsho nokusila kunye nokusila kunye nokusila kunye ne-attachment yokugaya.

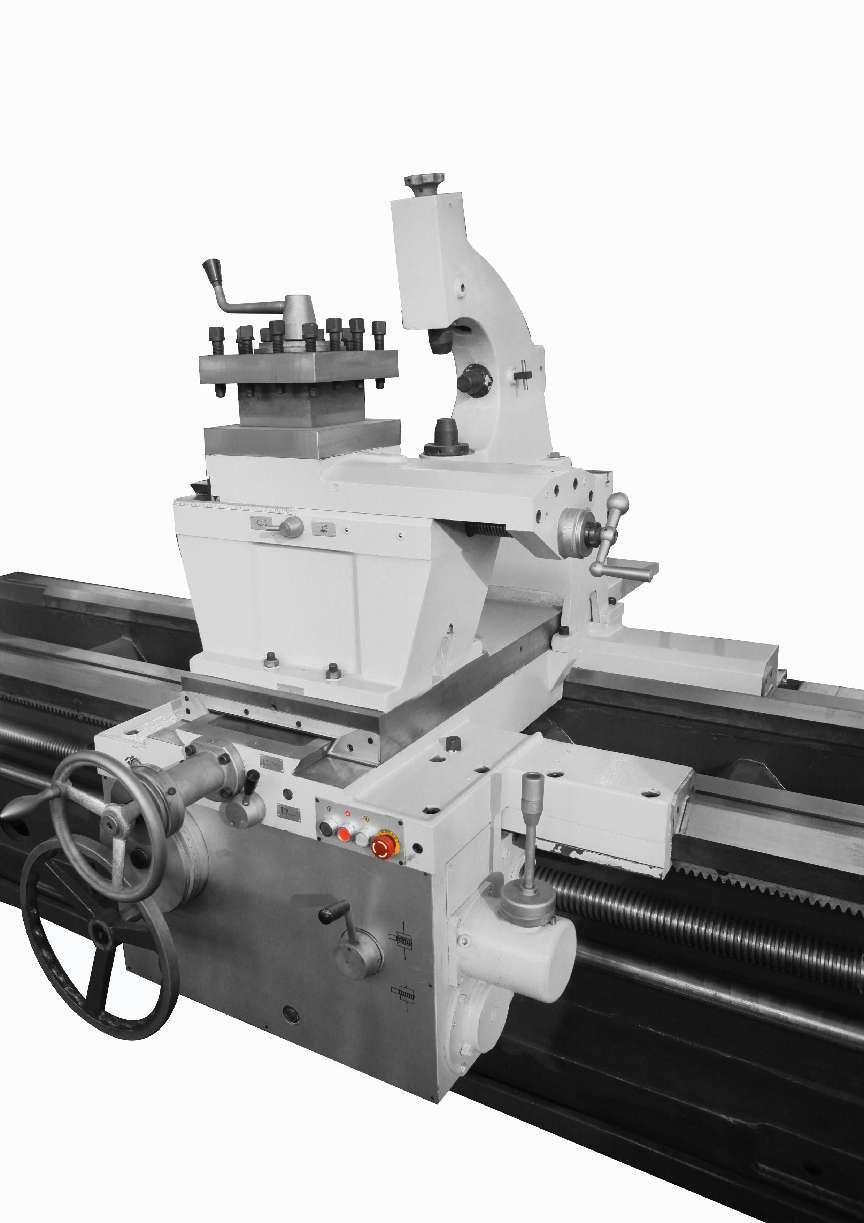

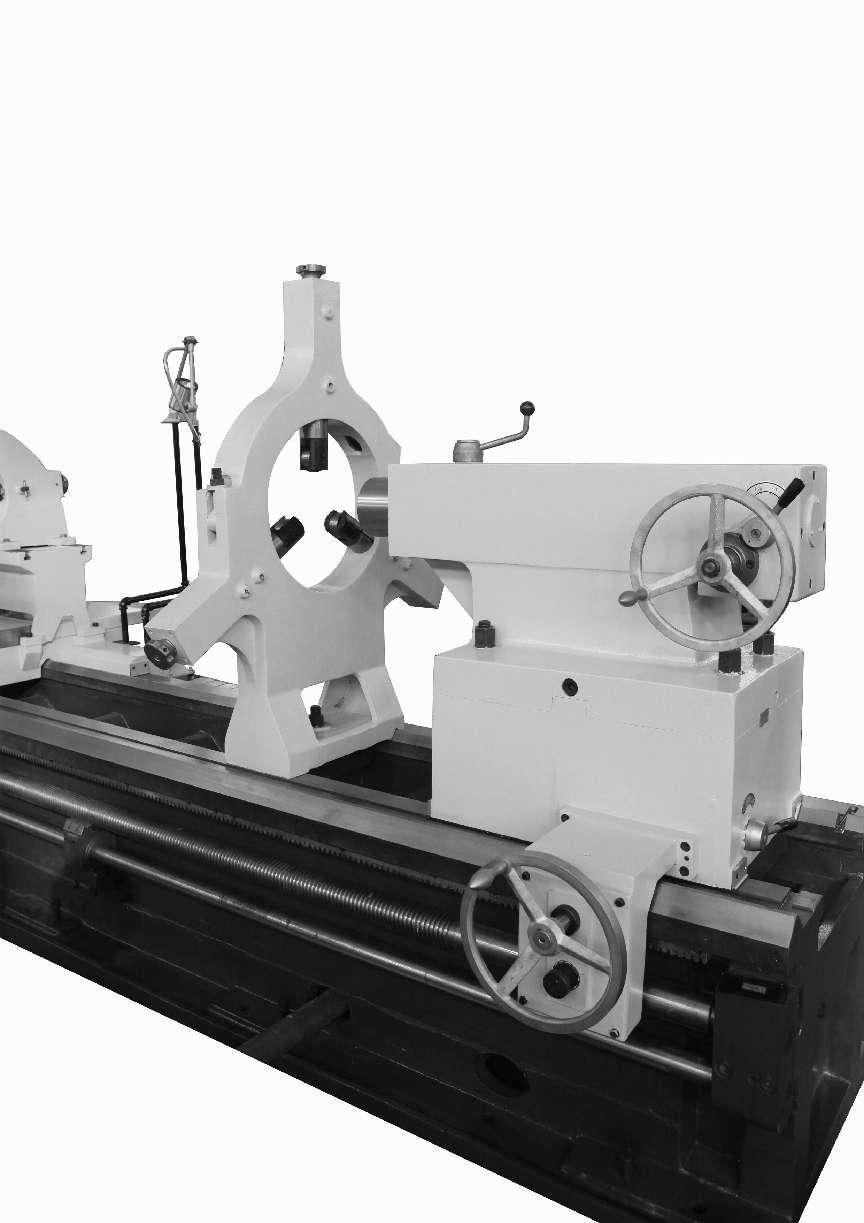

Amacandelo aphambili eoomatshini abaqhelekileyo: ibhedi, isitokhwe sentloko, ibhokisi yokutya, iposti yesixhobo, inqwelo, isitokhwe, kunye nemoto.

Ibhedi: Iindawo eziphambili zeumatshini wokuhlambazifakwe phezu kwebhedi, ukwenzela ukuba zigcine indawo echanekileyo yesalamane ngexesha lomsebenzi.I-carriage kunye ne-tailstock slide kwindawo yombhede owenziwe kakuhle.

Headstock:I-headstock ixhonywe ngokungqongqo ebhedini kwaye ibambe zonke iindlela, kubandakanya iintlobo ezahlukeneyo kunye nokudityaniswa kweepulleys okanye iigiya.Umsebenzi wayo ophambili kukudlula intshukumo ejikelezayo ukusuka kwimotor ephambili ngothotho lweendlela zokutshintsha isantya ukuze ishaft ephambili. iyakwazi ukufumana isantya esahlukileyo esifunekayo sokujikeleza phambili kunye nokubuyisela umva, kwaye ngexesha elifanayo, i-headstock iyahlula inxalenye yamandla okuhambisa isindululo kwibhokisi yokutya.I-Headstock Medium spindle yinxalenye ephambili ye-lathe.Ubushelelezi be-spindle. ukusebenza kwibheringi kuchaphazela ngokuthe ngqo umgangatho wokucubungula we-workpiece. Nje ukuba ukuchaneka kokujikeleza kwe-spindle kuncitshisiwe, ixabiso lokusetyenziswa kweisixhobo somatshiniiya kuncitshiswa.

Ibhokisi yesondlo: Ibhokisi yesondlo ixhotyiswe ngendlela yokutshintsha isantya kwintshukumo yokutya. Lungisa indlela yokutshintsha isantya ukuze ufumane isixa sokutya esifunekayo okanye inowuthi, kwaye uthumele isindululo kwisibambi sesixhobo nge-screw egudileyo okanye isikrufu sokukhokela ukusika. Isikrufu sokukhokela sisetyenziselwa ngokukodwa ukujika imisonto eyahlukeneyo. Xa ujika ezinye iindawo zokusebenzela, kuphela isikrufu esigudileyo sisetyenziswa endaweni yesikrufu sokukhokela.

Isibambi sesixhobo: Umphathi wesixhobo uqulunqwe ngamanqwanqwa amaninzi ezithuba zesixhobo. Umsebenzi wayo kukuxinanisa isixhobo kwaye wenze isixhobo sihambe ngobude, ecaleni okanye ngokuthobileyo.

I-Tailstock: Njengeziko elingasemva lokuxhasa indawo, inokufakwa kunye nezixhobo zokulungisa umngxuma ezifana ne-drills kunye ne-reamers yokucubungula umngxuma.

iinxalenye

I-chuck yemihlathi emithathu (yemisebenzi yecylindrical)

ichuck yemihlathi emine (yemisebenzi engaqhelekanga)

uphawu

Izixhobo zoomatshini eziqhelekileyozinesakhiwo esilula, umsebenzi olula, idiameter enkulu yokuphotha, unyawo oluncinci, ukuguquguquka okukhulu kokusetyenzwa, ukugcinwa lula, ukulungele ukusetyenzwa kwebhetshi encinci kunye nokusebenza kweendleko eziphezulu.

Ibhedi ithatha ibhedi edibeneyo kunye ne-rigidity ephezulu.Umatshini uxhotywe ngepompo yeoli eyahlukileyo. Isilayidi, isibambi sesixhobo, kunye nesali zinokuhamba ngokukhawuleza. Esi sixhobo somatshini sinokuthatha inkqubo ye-GSK okanye i-SIEMENS ekhethiweyo, inkqubo yokulawula amanani e-FANUC kunye nezinye iinkqubo zokulawula amanani ngokweemfuno zomsebenzisi, ezinokwenza ukusika okuphezulu, okunamandla kunye nokuzinza, ukuchaneka kwe-machining ephezulu kunye neprogram elula.

Iethe nkqo kwaye ethe tyeifidi yamkela i-AC servo motor, kwaye ingxelo ye-pulse encoder isetyenziswa njengenqaku lengxelo. Imizila yesikhokelo esithe nkqo nesithe tyaba siphantsi kokuqina kwe-ultrasonic kunye nonyango olucolekileyo lokugaya. Umzila wesikhokelo sebhedi ufakwe kwi-PTFE tape ethambileyo, kwaye i-coefficient ye-friction incinci.

Imoto ephambili ithatha imo edityanisiweyo yolawulo lwesantya solawulo lwemagnethi kunye nolawulo lwevolthi, ukuze yenze umgaqo wesantya esingena nyathelo.

Iinkqubo zokusebenza

1. Ukuhlolwa phambi kokuqaliswa

1.1 Yongeza igrisi efanelekileyo ngokwetshathi yomatshini wokuthambisa.

1.2 Qwalasela zonke izixhobo zombane, umqheba, iinxalenye zothumelo, izixhobo zokukhusela kunye nokunciphisa izixhobo ziphelele, zithembekile kwaye ziguquguquka.

1.3 Isixhobo ngasinye kufuneka sibe kwindawo ye-zero, kwaye ukunyanzeliswa kwebhanti kufuneka kuhlangabezane neemfuno.

1.4 Akuvumelekanga ukugcina izinto zetsimbi ngokuthe ngqo ebhedini, ukuze ungonakalisi ibhedi.

1.5 Umsebenzi oza kucutshungulwa awunaludaka nesanti, ukuthintela udaka kunye nesanti ukuba zingaweli kumatshini kwaye ziguge isiporo sesikhokelo.

1.6 Ngaphambi kokuba i-workpiece igxininiswe, kufuneka kwenziwe uvavanyo lwemoto olungenanto, kwaye i-workpiece inokulayishwa kuphela emva kokuqinisekisa ukuba yonke into iyinto eqhelekileyo.

2. Inkqubo yokusebenza

2.1 Emva kokuba i-workpiece ifakwe, qalisa impompo yeoli yokuthambisa kuqala ukuze wenze uxinzelelo lweoyile luhlangabezane neemfuno zesixhobo somatshini ngaphambi kokuba uqale.

2.2 Xa ulungelelanisa i-rack gear rack, xa ulungelelanisa ivili lokulenga, umbane kufuneka unqunyulwe. Emva kokulungelelaniswa, zonke iibholiti kufuneka ziqiniswe, i-wrench kufuneka isuswe ngexesha, kwaye i-workpiece kufuneka ikhutshwe ukuze isebenze ngokulinga.

2.3 Emva kokulayisha kunye nokukhulula i-workpiece, i-chuck wrench kunye neendawo ezidadayo ze-workpiece kufuneka zisuswe ngokukhawuleza.

2.4 I-tailstock, i-crank handle, njl. njl

2.5 Izixhobo zokusebenza, izixhobo zokusebenza kunye nezixhobo kufuneka zixhonywe ngokukhuselekileyo. Isixhobo samandla adadayo kufuneka sandise i-lead-in part kwi-workpiece ngaphambi kokuqala isixhobo somatshini.

2.6 Xa usebenzisa indawo yokuphumla yeziko okanye indawo yokuphumla, iziko elo malihlenga-hlengiswe kakuhle, yaye makubekho i-lubrication elungileyo neendawo zoqhagamshelwano ezixhasayo.

2.7 Xa ulungisa izinto ezinde, inxalenye ephumayo emva kwe-shaft engundoqo akufanele ibe yinde kakhulu.

2.8 Xa utyisa imela, imela kufuneka isondele emsebenzini kancinane ukuthintela ukungqubana; isantya senqwelo kufuneka sifane. Xa utshintsha isixhobo, isixhobo kunye nesixhobo somsebenzi kufuneka sigcinwe kumgama ofanelekileyo.

2.9 Isixhobo sokusika kufuneka siqiniswe, kwaye ubude bokwandiswa kwesixhobo sokuguqula ngokuqhelekileyo abukho ngaphezu kwama-2.5 ubukhulu besixhobo.

2.1.0 Xa kusetyenzwa iindawo eziziintsintsi, kufuneka kubekho ubunzima obuchanekileyo bokulinganisa umbindi womxhuzulane we-chuck, kwaye isantya sesithuthi masifaneleke.

2.1.1. Kufuneka kubekho imilinganiselo yokukhusela i-workpiece ene-chuck engaphaya kwe-fuselage.

2.1.2 Uhlenga-hlengiso lwesethingi yesixhobo malucothe. Xa isicatshulwa sesixhobo si-40-60 mm kude nenxalenye yokucubungula ye-workpiece, i-manual okanye isondlo sokusebenza kufuneka sisetyenziswe endaweni yoko, kunye nokutya okukhawulezayo akuvumelekanga ukuba kubandakanyeke ngqo isixhobo.

2.1.3 Xa upholisha i-workpiece ngefayile, isibambi sesixhobo kufuneka sibuyiselwe kwindawo ekhuselekileyo, kwaye umqhubi kufuneka ajongane ne-chuck, ngesandla sasekunene ngaphambili kunye nesandla sasekhohlo ngasemva. Kukho isitshixo ebusweni, kwaye kunqatshelwe ukusebenzisa ifayile ukucubungula i-workpiece kunye nomngxuma wesikwere.

2.1.4 Xa upholisha isangqa sangaphandle se-workpiece ngelaphu le-emery, umqhubi kufuneka abambe iziphelo zombini zelaphu le-emery ngezandla zozibini ukuze azipolishe ngokwendlela yokuma echazwe kwinqaku elidlulileyo. Akuvumelekanga ukusebenzisa iminwe yakho ukubamba ilaphu le-abrasive ukupolisha umngxuma ongaphakathi.

2.1.5 Ngexesha lokutya okuzenzekelayo, umnini-mela omncinci kufuneka ulungelelaniswe ukuze uhlambuluke kunye nesiseko ukukhusela isiseko ekuthinteni i-chuck.

2.1.6 Xa usikwa ii-workpieces ezinkulu nezinzima okanye izixhobo, kufuneka kugcinwe isibonelelo esaneleyo somatshini.

3. Umsebenzi wokupaka

3.1 Sika umbane kwaye ususe i-workpiece.

3.2 Iziphatho zenxalenye nganye ziwiswa phantsi ukuya kwindawo enguziro, kwaye izixhobo zibalwe zize zicocwe.

3.3 Jonga imeko yesixhobo ngasinye sokukhusela.

4. Izilumkiso ngexesha lokusebenza

4.1 Akuvumelekanga ngokungqongqo ukuba abantu abangasebenziyo basebenzise umatshini.

4.2 Akuvumelekanga ngokungqongqo ukubamba isixhobo, inxalenye ejikelezayo yesixhobo somatshini okanye i-workpiece ejikelezayo ngexesha lokusebenza.

4.3 Akuvumelekanga ukusebenzisa isitophu sikaxakeka. Kwimeko yongxamiseko, emva kokusebenzisa eli qhosha ukuyeka, kufuneka lihlolwe kwakhona ngokwemigaqo ngaphambi kokuqala isixhobo somatshini.

4.4 Akuvumelekanga ukunyathela kumphezulu kaloliwe wesikhokelo, isikrufu intonga, intonga epolishiweyo, njl.njl. Ngaphandle kwemimiselo, akuvumelekanga ukusebenzisa isibambo ngeenyawo endaweni yezandla.

4.5 Kwiindawo ezinamabhula, imingxuma eyanciphayo okanye izitshixo eludongeni lwangaphakathi, i-triangular scrapers ayivumelekanga ukusika imingxuma yangaphakathi.

4.6 Umoya ocinezelweyo okanye uxinzelelo lolwelo lwe-pneumatic hydraulic chuck yangasemva kufuneka lufikelele kwixabiso elichaziweyo phambi kokuba lusetyenziswe.

4.7 Xa ujika ii-workpieces ezibhityileyo, xa ubude obuphumayo bamacala amabini angaphambili entloko yebhedi bungaphezu kobukhulu obuphindwe ka-4 ububanzi, iziko kufuneka lisetyenziswe ngokwemigaqo yenkqubo. Ukuphumla kweziko okanye inkxaso yokuphumla kwesithende. Abalindi kunye neempawu zokulumkisa kufuneka zongezwe xa ziphuma emva kwentloko yebhedi.

4.8 Xa usika isinyithi esiqhekezayo okanye ukusika ukutshiza ngokulula (kubandakanywa nokugaya), ii-baffles zokukhusela kufuneka zongezwe, kwaye abaqhubi kufuneka banxibe iiglasi zokukhusela.

enye

Ngokuthandwa kweCNC Machining,ngakumbi nangakumbi izixhobo ezizenzekelayo zivela kwimarike.Iileyile zemvelibanezabo iingenelo ezingenakubuyiselwa kwaye basengoomatshini abayimfuneko kuninzi lwezityalo ezilungisayo.

1. Izixhobo zoomatshini eziqhelekileyozifikeleleka ngakumbi

Iindleko zokuthenga zeCNC latheszibiza ngokuphindwe kaninzi kunesiqhelo i-lathe enamandla afanayo, kunye nokugcinwa kwexesha elizayo, ukulungiswa, ukuxhasa izinto ezisetyenziswayo kunye nezinye iindleko nazo ziphezulu kakhulu kunayo.

I-2.Ifaneleke ngakumbi kwi-machining encinci

Xa kuphela iibhetshi ezincinci zezixhobo zokusebenza kufuneka zenziwe ngomatshini,uninzi lwabasebenzi abanezakhono banokumatshini inxalenye ngezixhobo zoomatshini eziqhelekileyo ngemizobo yamalungu.

3.Imivuzo ephezulu yeeprogram ze-CNC kunye neetalente ezimbalwa

Abaprogram be-CNC bahlala befuna imivuzo ephezulu, kwaye zininzi iintlobo zeenkqubo ze-CNC. Ngokucacileyo kunzima kakhulu ukufumana umsebenzi onobuchuleIzixhobo zoomatshini be-CNCkunomsebenzi wesixhobo somatshini oqhelekileyo.

4.Malunga neendleko zengeniso yeshishini

Ukuthathela ingqalelo i-capital turnover yamashishini kunye nokusetyenziswa okunengqiqo kwezixhobo, amashishini amaninzi agcina ukuvelisaumatshini oqhelekileyoizixhobo.

Lilonke, nangona ukuveliswa kwe-CNC kuye kwaba yinto ephambili ekuphuhliseni ishishini lokuvelisa, izixhobo zoomatshini eziqhelekileyo zisenazo iingenelo ezikhethekileyo kwimeko yokuthandwa kwezixhobo ezikrelekrele. Ngokuphuculwa okuqhubekayo kobukrelekrele beIzixhobo zoomatshini be-CNCkwixesha elizayo, izixhobo zoomatshini besintu zinokutshintshwa kumlinganiselo omkhulu, kodwa akunakwenzeka ukuba zipheliswe ngokupheleleyo.

| UMZEKELO | CW61(2)63E | CW61(2)80E | CW61(2)100E | CW61(2)120E | CWA61100 |

| IZAKHONO | |||||

| UMax.ujingi phezu kwebhedi | 630mm | 800mm | 1000mm | 1200mm | 1000mm |

| UMax.ujiwuzi phezu kwesilayidi esinqamlezileyo | 350mm | 485mm | 685mm | 800mm | 620mm |

| Ubude obugqithisayo | 750,1250,1750,2750,3750,4750,5750,7750,9750,11750mm | 1.5m 2m 3m 4m 5m 6m 8m 10m 12m | |||

| Max.ujingi phezu komsantsa | 830mm | 1000mm | 1200mm | 1400mm | 780mm |

| Ubude obusebenzayo besithuba | 230m | 8T | |||

| Ububanzi bebhedi | 550mm | ||||

| INTLOKO-MTOWU | Φ130mm | ||||

| Umngxuma wokusonta | 105mm OKANYE 130mm (KUZIKHETHELA CW6180E+) | Metric140# | |||

| Impumlo yokusonta | D-11 okanye C-11 | 3.15-315r / min okanye 2.5-250r / min | |||

| I-Spindle taper | Φ120mm taper1:20(Φ140, UKHETHA KU-CW6180+) | Phambili 21iintlobo,Ukubuyisela umva12iintlobo | |||

| Izantya zokujikeleza(Inombolo) | 14-750RPM(18 AMANYATHELO) | ||||

| IBHOKISI YEGEAR-IMICHA & IFEED | 44iintlobo 1-120mm | ||||

| Uluhlu lwemisonto yemetric (iintlobo) | 1-240mm(54 iintlobo) | 31iintlobo 1/4-24 T/I | |||

| Imisonto ye-intshi irenge (Iintlobo) | 28-1 intshi(36 iintlobo) | 45iintlobo 0.5-60mm | |||

| Uluhlu lwemisonto ye-Module (iintlobo) | 0.5-60 DP(27 iindidi) | 38iintlobo 1/2-56DP | |||

| Uluhlu lwemisonto yediametral (iintlobo) | 30-1 tpi(27 iintlobo) | 56iintlobo 0.1-12mm | |||

| Uluhlu lokutya okude (iintlobo) | 0.048-24.3mm/r (iintlobo ezingama-72) | 56iintlobo 0.05-6mm | |||

| Uluhlu lokutya okunqamlezileyo(iintlobo) | 0.024-12.15mm/r (iintlobo ezingama-72) | 3400mm/min,1700mm/min | |||

| Ukutya okukhawulezayo:Kude./Umnqamlezo | 4/2m/min | ||||

| Ubungakanani be-Leadscrew: I-Diameter/Pitch | T48mm/12mm OKANYE T55mm/12mm(ye-5M+) | 48mm | |||

| INKQUBO | 45*45mm | ||||

| Ukuhamba ngezilayidi ezinqamlezayo | 350mm | 420mm | 520mm | ||

| Uhambo lokuphumla oludibeneyo | 200mm | 650mm | |||

| Ubungakanani beshank yesixhobo | 32*32mm | 280mm | |||

| TAILSTOCK | |||||

| Idayamitha ye-Spindle | 100mm | 120mm | Φ160mm | ||

| I-Spindle taper | ORSE #6 | Metric 80# | |||

| Ukuhamba nge-spindle | 240mm | 300mm | |||

| IMOTO | |||||

| Injini yokuqhuba ephambili | 11kw | 22kw | |||

| Impompo yemoto epholileyo | 0.09kw | 0.15kw | |||

| Ukutya okukhawulezileyo injini | 1.1kw | 1.5kw | |||

Ixesha lokuposa: Apr-14-2022