Kokokuqala ukuba abathengi abakweminye imimandla ekhethekileyo badibane naboCNC lathes, kunye nokusebenza kweelayile ze-CNC akukakwazi ukuqonda izakhono zokusebenza zomatshini kuphela kwisikhokelo sencwadana yokusebenza. Ukudibanisa amava okusebenza aqokelelwe ngamavaChina CNC latheabaqhubi kumsebenzi wabo wemihla ngemihla, ndiya kuchaza izakhono zokumisela isixhobo kunye namanyathelo okucubungula amanye amacandelo.

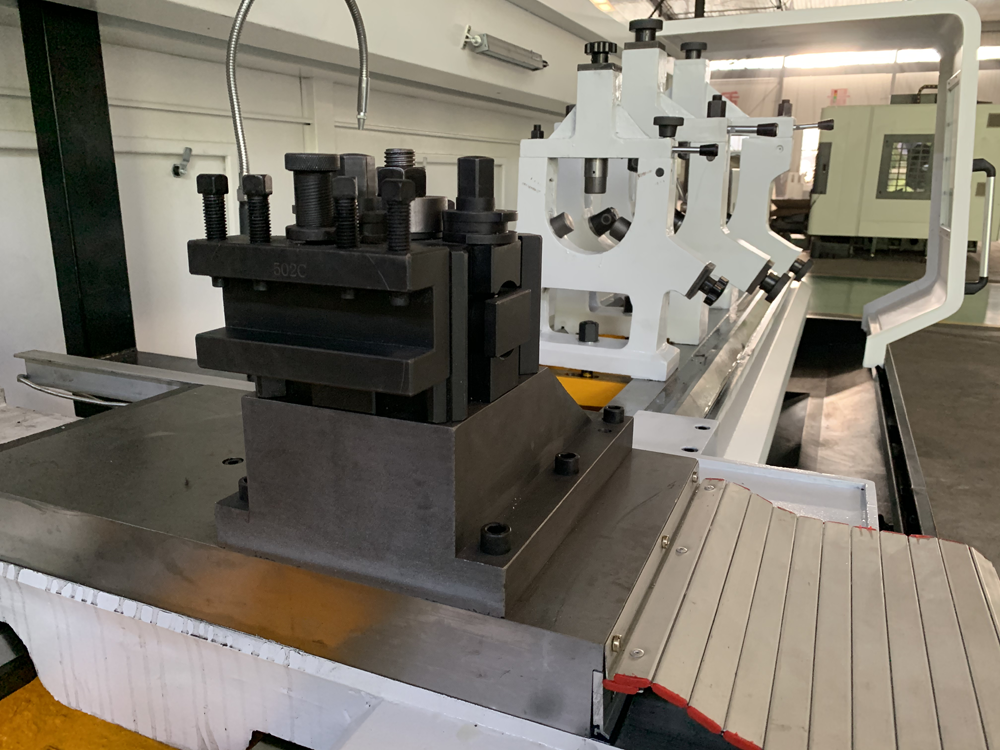

Iindlela kunye nezakhono zokumisela izixhobo kwishishini lomatshini zingahlulwa zibe ngamacandelo amabini: ukusetwa kwesixhobo esithe ngqo kunye nokusetwa kwesixhobo. Ngaphambi kokuba i-lathe ye-CNC ibuyele kwindawo yokuqala, yonke intoukujika kwakhonal ekufuneka isetyenziswe icwangciswe nendawo esembindini yobuso bokungqusha obusekunene bendawo njengenqaku le-0, kwaye ke indawo esembindini yobuso obujikekayo bendawo ikhethwa njengenqaku le-0 kwayeisixhobo CNCinqaku libekiwe. Xa isixhobo sokujika sichukumisa ikhibhodi yobuso bokusila ekunene, igalelo Z0 kwaye nqakraza ukubona, ixabiso lembuyekezo yesixhobo sesixhobo sokujika liya kugcina ngokuzenzekelayo idatha ebhaqiweyo, okuthetha ukuba isicwangciso sesixhobo se-Z-axis sigqityiwe, kunye nokusetha isixhobo se-X. sisixhobo sokusika isixhobo sovavanyo, kwaye i-cutter yokugaya iyasetyenziswa Isangqa sangaphandle samalungu emoto sincinci, kunye nedatha yesangqa sangaphandle semoto ebhaqiweyo (ezifana no x yi-20 mm) igalelo lekhibhodi x20, cofa ukubona, isixhobo ixabiso lembuyekezo liya kugcina ngokuzenzekelayo idatha eboniweyo, ngeli xesha i-x-axis nayo igqityiwe.

Olu hlobo lwendlela yokucwangcisa isixhobo, nokuba iCNC latheiphelelwe ngamandla, ixabiso lokucwangcisa isixhobo aliyi kutshintshwa emva kokuba amandla eqalwe ngokutsha. Ingasetyenziswa kwibhetshi yemveliso yexesha elide kunye nokusetyenzwa kwamalungu afanayo. Ngeli xesha, umatshini awufuni ukuphinda ulinganiswe xa umatshini uvaliwe.

Amanyathelo okulungisa iinxalenye

Amanyathelo okulungisa iinxalenye

(1) Gcoba ngenqindi kuqala uze emva koko ube mcaba (oku kukuphepha ukushwabana xa ubetha).

(2) Ukujika okurhabaxa kuqala, emva koko ukujika kakuhle (oku kukuqinisekisa ukuchaneka kwamalungu).

(3) Okokuqala qhubekisa abo banezikhewu ezinkulu uze wenze ezo zinezithuba ezincinci (oku kukuqinisekisa ukuba indawo yangaphandle yesayizi encinci ye-gap ayikrwempanga kwaye uphephe ukugqwesa iindawo).

(4) Khetha umlinganiselo ochanekileyo wesantya, isixa esisikiweyo kunye nobunzulu bokusikwa ngokwemigangatho yokuqina kwayo. Isixhobo se-carbon steel plate sikhethwe ukujikeleza ngesantya esiphezulu, umthamo ophezulu wokusika, kunye nobunzulu obukhulu bokusika. Njenge: 1Gr11, sebenzisa i-S1 600, F0.2, kunye nokusika ubunzulu be-2 mm. I-alloy isebenzisa umlinganiselo ophantsi wesantya, izinga lokutya eliphantsi kunye nobunzulu obuncinci bokusika. Ezinje: GH4033, khetha S800, F0.08, kwaye usike ubunzulu 0.5mm. Intsimbi ye-Titanium alloy ikhetha umlinganiselo ophantsi wesantya, umthamo ophezulu wokusika, kunye nobunzulu obuncinci bokusika. Ezinje: Ti6, sebenzisa S400, F0.2, kwaye usike ubunzulu 0.3mm. Thatha imveliso yenxalenye ethile njengomzekelo: imathiriyeli yi-K414, into enzima kakhulu. Emva kweemvavanyo eziphindaphindiweyo, ukhetho lokugqibela luyi-S360, F0.1, kunye nobunzulu be-cut 0.2, ngaphambi kokuba iinxalenye ezisemgangathweni zingaveliswa. (Oku kwenzelwa ireferensi kuphela, nceda wenze uhlengahlengiso olululo olusekwe kwiparamitha zoomatshini kwindawo, izixhobo, njl.njl kwiimeko ezithile!)

Ixesha lokuposa: Nov-29-2021