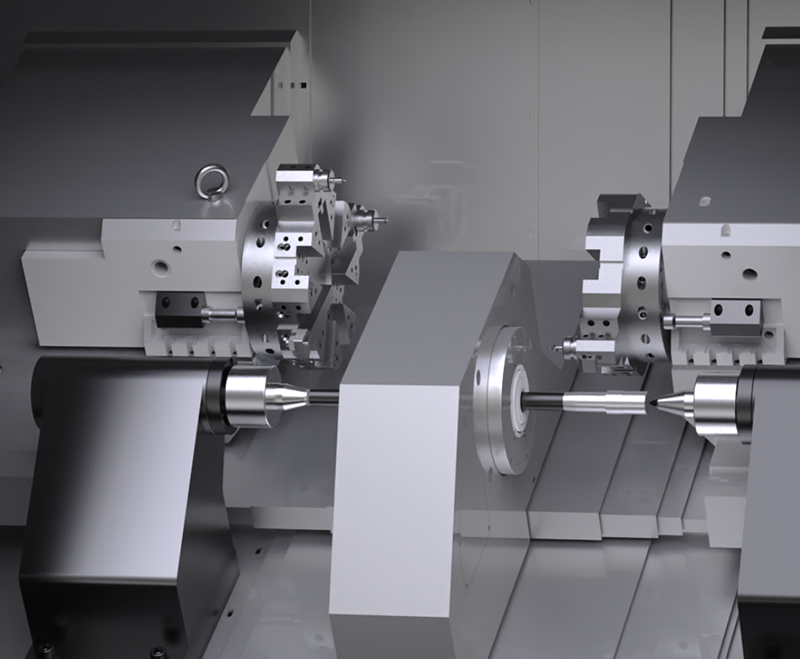

Iintambo ezimbini ze-CNC ezijikelezayozizixhobo ezibalulekileyo kwimveliso yanamhlanje, kunye nozinzo lwazo lokusebenza kunye nokulungiswa kokuchaneka okuchaphazela ngokuthe ngqo ukusebenza kwemveliso kunye nomgangatho wemveliso. Ngoko ke, ukugcinwa kwemihla ngemihla kwaba matshini kubaluleke kakhulu. Ngokugcinwa okufanelekileyo, kungekuphela nje ixesha lokuphila kwesixhobo, kodwa ukuchaneka kwayo kunye nozinzo lokusebenza kunokuqinisekiswa, ngaloo ndlela kuphuculwe ukusebenza kakuhle kwemveliso kunye nokunciphisa iindleko zokugcina.

Ukubaluleka koLondolozo lweMihla yonke

1.Ukwandisa ubomi beSixhobo

I-lathes ye-CNC ene-spindle ephindwe kabini namava ahlukeneyo okunxiba kunye nefuthe kumalungu abo ngexesha lokusetyenziswa. Ukucocwa rhoqo, ukuthambisa, kunye nokuhlola kunokunceda ukuchonga nokujongana nemiba enokubakho, efana nezikhokelo ezigugileyo kunye nezibophelelo ezixekileyo, ukuthintela iingxaki ezincinci ekubeni zibe ziimpazamo ezinkulu kunye nokwandisa ngokufanelekileyo ubomi bubonke besixhobo.

2.Ukuqinisekisa ukuchaneka kweSixhobo

Ukuchaneka kokucubungula kweI-Spindle ephindwe kabini ye-CNC latheluphawu oluphambili lomsebenzi wabo. Ukuchaneka kwamacandelo abalulekileyo njengezikhokelo kunye nezikrufu zokukhokela zichaphazela ngokuthe ngqo ukuchaneka komgangatho kunye nomgangatho womphezulu wamalungu acutshungulweyo. Ngokulungiswa kwemihla ngemihla, njengokucoca rhoqo inkunkuma evela kwizikhokelo kunye nezikrufu ezikhokelayo zokuthambisa, la macandelo anokugcina ukuchaneka kwawo, ukuqinisekisa ukuba iinxalenye ezicutshungulweyo ziyahlangabezana neemfuno zoyilo.

3.Ukuphucula ukuzinza kunye nokuthembeka kokuSebenza

Ngexesha lokusebenza, i-lathes ye-CNC ene-spindle ephindwe kabini ifuna ukusebenza ngokulungelelanisiweyo kweendlela ezahlukeneyo, kubandakanya umbane, ukupholisa, kunye neenkqubo zokuthambisa. Nakuphi na ukungaphumeleli kwezi nkqubo zingaphantsi kunokukhokelela ekuphelelweni kwexesha lezixhobo, okuchaphazela iishedyuli zemveliso. Ukugcinwa rhoqo, njengokujonga uxhulumaniso lwekhebula, ukucoca iinkqubo zokupholisa, kunye nokutshintshwa kwezinto zokuthambisa, kuqinisekisa ukuba zonke ii-subsystems zisebenza ngokufanelekileyo, ziphucula ukuzinza kunye nokuthembeka kwezixhobo.

4.Ukunciphisa iFault Rates kunye neendleko zoLondolozo

Ukugcinwa rhoqo kunokuchonga kunye nokujongana neziphene ezinokubakho ngokukhawuleza, ukuthintela ilahleko yemveliso ngenxa yokusilela kwezixhobo. Ukongezelela, ishedyuli yokulondolozwa kakuhle ecwangcisiweyo inokwandisa umjikelo omkhulu wokulungiswa kwesixhobo, ukunciphisa iindleko zokulondoloza.

Iindlela ezithe ngqo zoLondolozo

1.Ukucoca rhoqo kunye nokuthambisa

Ukucocwa kwesikhokelo: Izikhokelo ezicocekileyo rhoqo ukugcina ukuguda kunye nokuchaneka kwazo.

I-Lead Screw Lubrication: Rhoqo thambisa izikrufu zelothe ukunciphisa ukukhuhlana kwaye ugcine ukuchaneka kwazo kunye nobomi.

Ukuhlolwa kweNkqubo yokuthambisa: Qwalasela inqanaba le-oyile yenkqubo yokuthambisa rhoqo kunye nomgangatho ukuze uqinisekise ukuba isebenza ngokuqhelekileyo.

2.Ukuhlolwa kweNkqubo yoMbane

UkuJonga uQhagamshelwano lweCable: Rhoqo hlola uqhagamshelo lweentambo ukuqinisekisa ukuba zikhuselekile.

Ukujonga iCandelo loMbane: Hlola rhoqo amacandelo ombane, afana nokuhanjiswa kunye nabafowunelwa, ukuqinisekisa ukuba basebenza ngokufanelekileyo.

3.Ukugcinwa kweNkqubo yokuPholisa

Ukujonga ukupholisa: Hlola ubushushu besipholisi rhoqo kunye nomgangatho ukuqinisekisa ukuba isixokelelwano sokupholisa sisebenza ngesiqhelo.

Ukucocwa kweNkqubo yokupholisa: Hlambulula rhoqo inkqubo yokupholisa ukuze ususe inkunkuma kwaye ugcine ukucoceka kwayo.

4.Isixhobo seMagazini kunye neSixhobo sokuTshintsha uLondolozo

Ukucocwa kweMagazini yeSixhobo: Coca rhoqo imagazini yesixhobo ukuze uqinisekise ukuba izixhobo zigcinwa kakuhle kwaye uphephe ukungqubana.

Ukuhlolwa koTshintsho lwesixhobo: Hlola rhoqo isixhobo sokutshintsha isixhobo ukuze uqinisekise ukuba sisebenza ngokuqhelekileyo.

5.Lathe Precision Maintenance

Ukujongwa kweNqanaba lokuHlola: Qwalasela indawo ekwinqanaba leleyile ukuze uqinisekise ukuchaneka kwayo.

Ulungelelwaniso lweMechanical Precision: Rhoqo ulungelelanisa ukuchaneka koomatshini ukugcina ukuchaneka kwe-lathe.

Ukuqulunqa iSicwangciso seSondlo

Ukuqinisekisa ukusebenza okuqhelekileyo kunye nobomi beumatshini wokusonta kabini we-CNC, iinkampani kufuneka ziphuhlise isicwangciso solondolozo esifanelekileyo ngokwenzululwazi. Esi sicwangciso kufuneka siquke:

UMjikelo wokuLondoloza: Misela ishedyuli yokulungisa rhoqo esekelwe kusetyenziso lwezixhobo kunye neengcebiso zomenzi.

Isiqulatho seSondlo: Chaza ngokucacileyo okuqulethwe yiseshoni yolondolozo nganye, njengokucoca, ukuthambisa, nokuhlola.

UQeqesho lwaBasebenzi bezoLondolozo: Ukubonelela ngoqeqesho oluyimfuneko kubasebenzi bezolondolozo ukuqinisekisa ukuba bayakwazi ukwenza imisebenzi ngokuchanekileyo.

Iirekhodi zoLondolozo: Gcina iirekhodi zogcino oluneenkcukacha ukulandelela ubume besixhobo kunye nembali.

Ngokuzalisekisa ngokungqongqo isicwangciso sokulondolozwa, iinkampani zinokuphucula ngokufanelekileyo ukusebenza kunye nokuzinza kwe-lathes ye-CNC ye-spindle ephindwe kabini, inika inkxaso eqinile kwimveliso kunye nophuhliso.

Isishwankathelo, ukugcinwa kwemihla ngemihla kwe-dual-spindleCNC lathekubalulekile ekuqinisekiseni ukusebenza okuqhelekileyo, ukwandisa ixesha lokuphila, ukuphucula ukusetyenzwa ngokuchanekileyo, kunye nokuphucula uzinzo. Iinkampani kufuneka ziwubeke phambili umsebenzi wolondolozo, ziphuhlise isicwangciso sokulungisa esinengqiqo, kwaye zisiphumeze ngokungqongqo ukuqhubeka nokuphucula ukusebenza kakuhle kwemveliso kunye nomgangatho wemveliso.

Ixesha lokuposa: Apr-02-2025