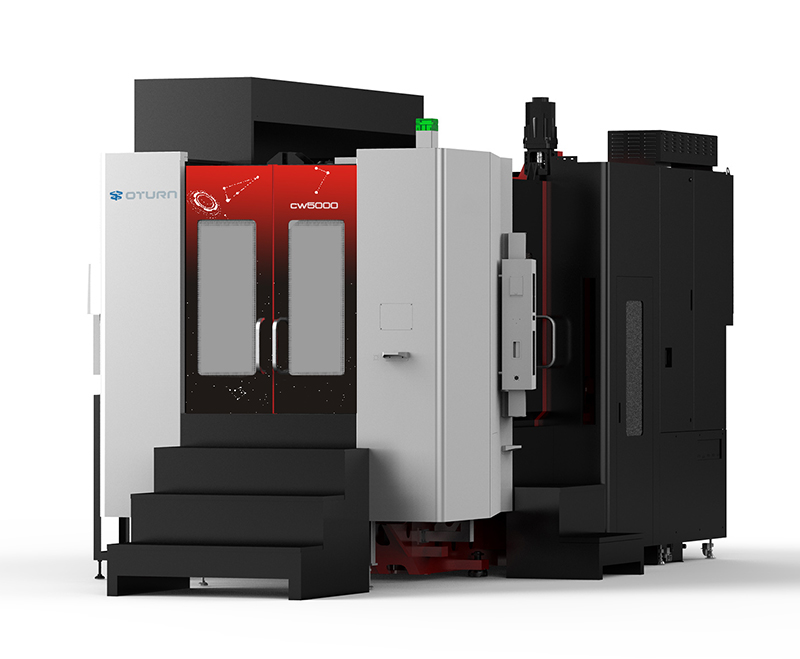

Iisikhululo-ezimbini CNC iziko machining oxwesileyosisixhobo esibalulekileyo sezixhobo zale mihla ezichanekileyo, ezisetyenziswa kakhulu kumashishini afana neemoto, i-aerospace, kunye nokuveliswa kokungunda ngenxa yokuqina kwayo okuphezulu, ukuchaneka okuphezulu, kunye nokusebenza okuphezulu.

Iimbonakalo:

Uyilo lweZitishi ezimbini: Ivumela esinye isikhululo ukuba senze oomatshini ngelixa esinye siphethe ukulayisha okanye ukothula, siphucula ukusebenza kakuhle komatshini kunye nokusetyenziswa kwezixhobo.

Ulwakhiwo oluthe tyaba: I-spindle icwangciswe ngokuthe tye, eququzelela ukususwa kwe-chip kwaye ifanele imveliso yobuninzi kunye nomatshini ozenzekelayo.

Ukuqina okuphezulu kunye nokuchaneka: Kufanelekile kumashishini afana ne-aerospace, ukuveliswa kweemoto, kunye nokulungiswa kwe-mold kufuna ukuchaneka okuphezulu kunye nokusebenza kakuhle.

Multi-Process Integration: Ukukwazi ukwenza ukujika, ukugaya, ukugaya, kunye nezinye iinkqubo zokutshiza ngexesha elinye, ukunciphisa ukuhanjiswa kwe-workpiece kunye neephoso zesibini ze-clamping.

Eli nqaku liza kuchaza iindlela ezininzi zokutshintsha izixhobo eziqhelekileyo ezisetyenziswa kwizitishi ezimbini ze-CNC ezithe tyaba zomatshini wokunceda abafundi baqonde ngcono kwaye basebenzise obu buchwepheshe.

1. Utshintsho lweSixhobo seManuwali

Utshintsho lwesixhobo seManuwali yeyona ndlela isisiseko, apho umqhubi ngesandla esusa isixhobo kwimagazini yesixhobo aze asifake kwi-spindle ngokweemfuno zomatshini. Le ndlela ifanelekile kwiimeko ezinezixhobo ezimbalwa kunye nesixhobo esisezantsi sokutshintsha frequency. Nangona kunzima, utshintsho lwesixhobo sezandla lusenalo ixabiso lalo kwiimeko ezithile, njengaxa iintlobo zesixhobo zilula okanye imisebenzi yobuchwephesha ayintsokothanga.

2. Utshintsho lweSixhobo oluzenzekelayo (Utshintsho lweSixhobo seRobhothi)

Iisistim ezizenzekelayo zokutshintsha izixhobo lulungelelwaniso oluqhelekileyo lwezitishi ezimbini zanamhlanjeCNC amaziko machining oxwesileyo. Ezi nkqubo ngokuqhelekileyo ziquka imagazini yesixhobo, ingalo yerobhothi etshintsha isixhobo, kunye nenkqubo yokulawula. Ingalo yerobhothi ikhawuleza ibambe, ikhethe, kwaye itshintshe izixhobo. Le ndlela ibonisa isantya sokutshintsha isixhobo esikhawulezayo, uluhlu oluncinci lwentshukumo, kunye ne-automation ephezulu, iphucula kakhulu ukusebenza kakuhle komatshini kunye nokuchaneka.

3. Utshintsho lwesixhobo esithe ngqo

Utshintsho lwesixhobo oluthe ngqo lwenziwa ngentsebenziswano phakathi kwemagazini yesixhobo kunye nebhokisi yokusonta. Kuxhomekeke ekubeni imagazini yesixhobo iyashukuma na, inguqu yesixhobo esithe ngqo inokwahlulwa ibe ziindidi zokutshintsha iimagazini kunye neemagazini. Kuhlobo lokutshintsha kwemagazini, imagazini yesixhobo iya kwindawo yokutshintsha isixhobo; kuhlobo olumiselweyo lwemagazini, ibhokisi yokusonta ishukuma ukukhetha nokutshintsha izixhobo. Le ndlela inesakhiwo esilula kodwa ifuna ukuhambisa imagazini okanye ibhokisi yokusonta ngexesha lotshintsho lwesixhobo, esinokuchaphazela isantya sokutshintsha isixhobo.

4. Turret Tool Change

Ukutshintsha isixhobo seTurret kubandakanya ukujikeleza i-turret ukuzisa isixhobo esifunekayo kwindawo yokutshintsha. Olu lwakhiwo ludityanisiweyo luvumela amaxesha amafutshane kakhulu okutshintsha isixhobo kwaye lulungele ukwenziwa komatshini ontsonkothileyo wamalungu abhityileyo afana neecrankshafts ezifuna imisebenzi emininzi yomatshini. Nangona kunjalo, utshintsho lwesixhobo se-turret lufuna ukuqina okuphezulu kwe-turret spindle kunye nokunciphisa inani lezixhobo zokuphotha.

Isishwankathelo

isikhululo-ezimbini CNC iziko machining oxwesileyozibonelela ngeendlela ezininzi zokutshintsha isixhobo, nganye ineempawu ezahlukileyo kunye nezicelo ezifanelekileyo. Ngokwesiqhelo, ukhetho lwendlela yokutshintsha isixhobo kufuneka luthathele ingqalelo iimfuno zoomatshini, ukucwangciswa kwezixhobo, kunye nemikhwa yabaqhubi ukukhetha esona sisombululo sifanelekileyo.

Ndijonge phambili ekudibaneni nawe kwi-CIMT 2025!

Ukususela nge-21 ku-Epreli ukuya kwi-26, 2025, iqela lethu lobugcisa liya kuba kwindawo e-CIMT 2025 ukuphendula yonke imibuzo yakho yobugcisa. Ukuba ufuna ukufunda malunga nokuphumelela kwamva nje kwitekhnoloji ye-CNC kunye nezisombululo, lo ngumsitho ongafuni ukuwuphoswa!

Ixesha lokuposa: Apr-18-2025