Ukusebenza kakuhle

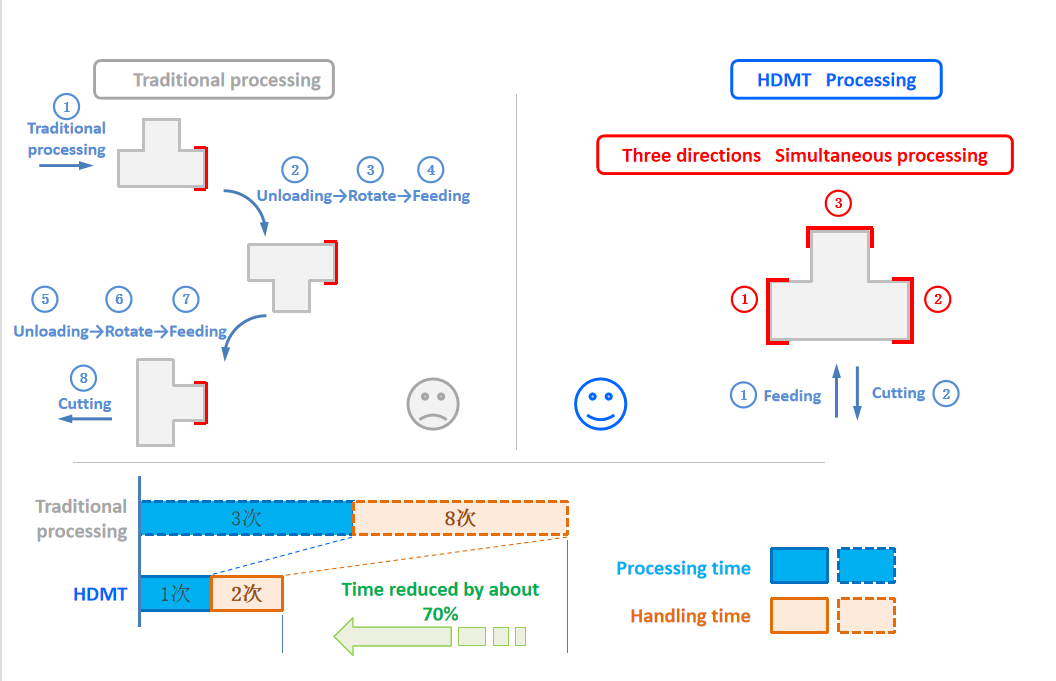

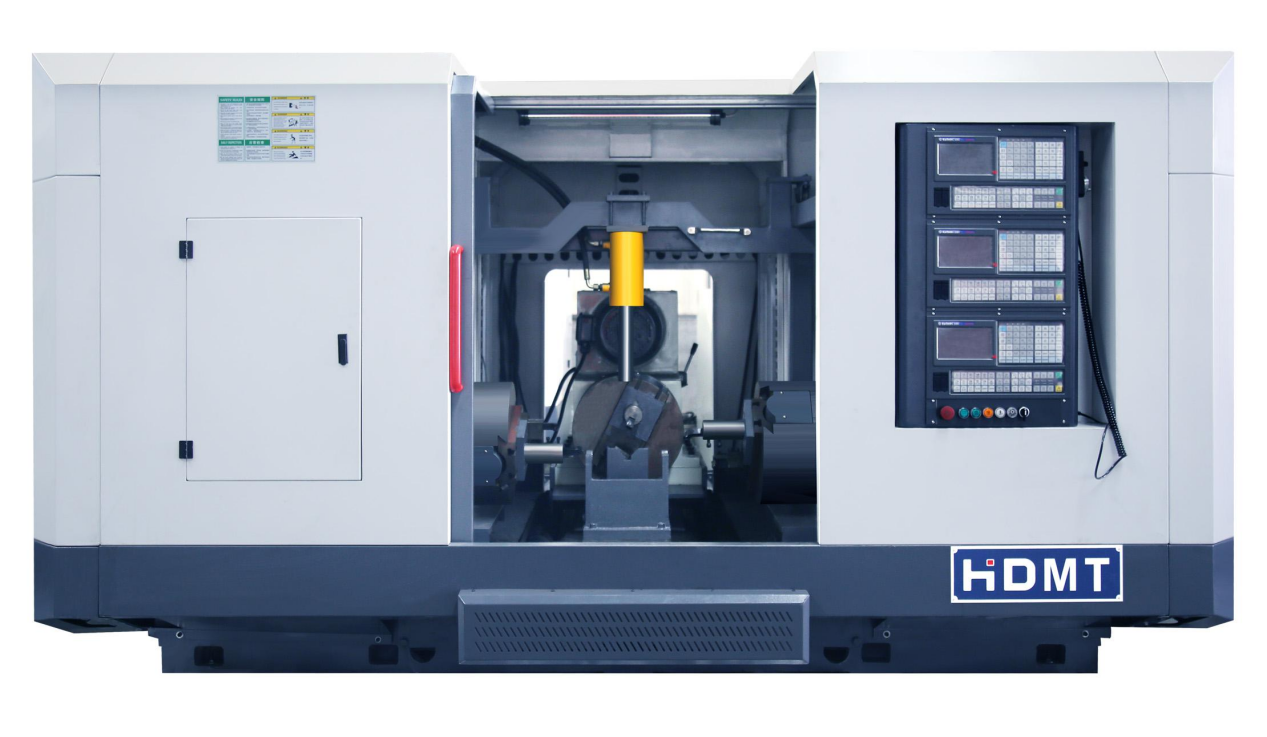

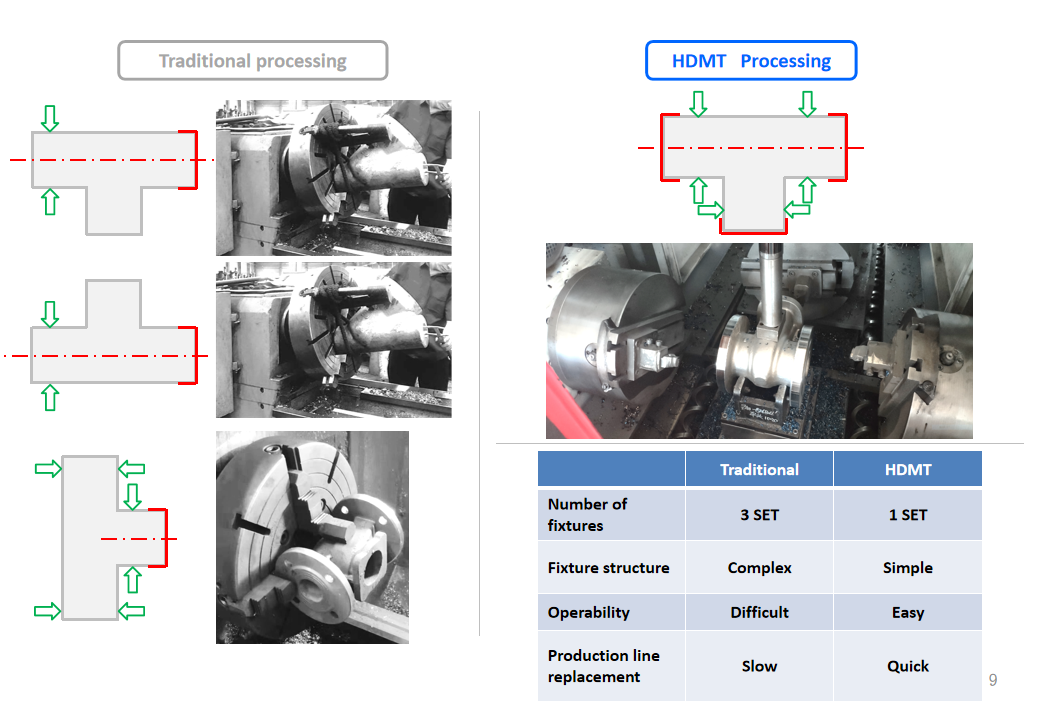

Umatshini wokucutshungulwa kwevalvu yemveli kufuneka ucubungule i-workpiece kathathu, kwaye kufuneka icinezelwe kwaye iqhutywe kathathu ngamaxesha amathathu, ngelixaI-HDMT CNC yoBuso obuThathu bokuTshintsha umatshiniinokucubungula ubuso obuthathu ngexesha elinye, kwaye i-workpiece inokugqitywa ngokulayishwa kunye nokukhulula enye kuphela. Ukusetyenzwa konga kakhulu ixesha lokuqhuba.

Utyalo-mali lweendleko

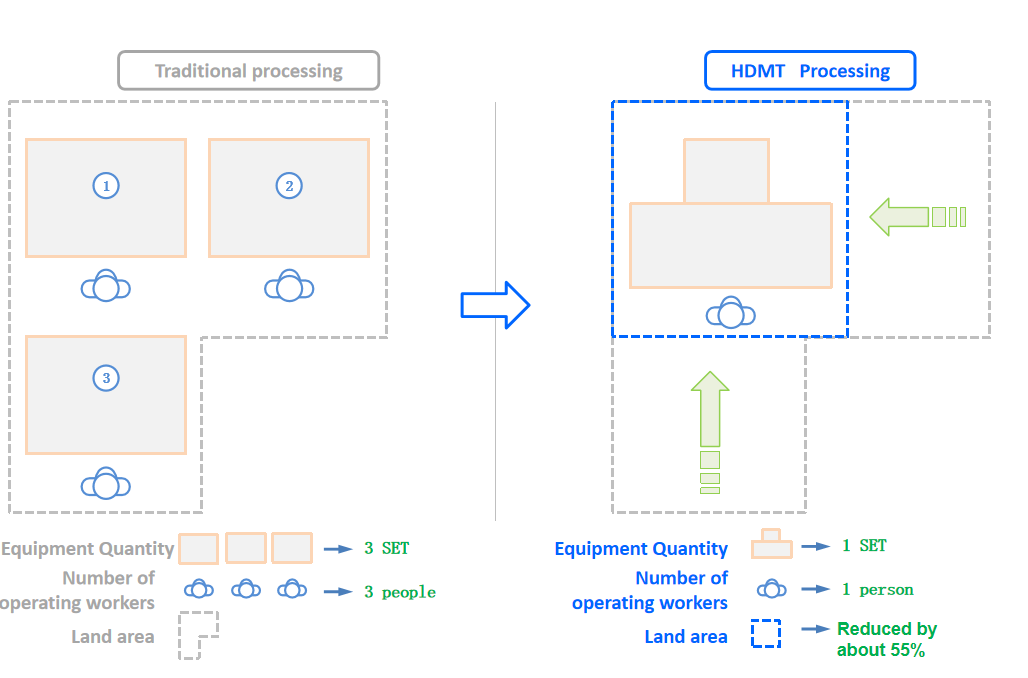

Indlela yokucubungula umatshini wevalve yemveli ifuna oomatshini abathathu kumacala amathathu, kwaye umatshini ngamnye kufuneka uxhotyiswe ngabasebenzi abahambelanayo, obandakanya indawo enkulu kunye neendleko eziphezulu.I-HDMT CNC yoBuso obuThathu bokuTshintsha umatshiniifuna kuphela umatshini omnye ukuze isebenze oogxa bamacala amathathu. Kufuneka ixhotyiswe kuphela ngabasebenzi bomatshini omnye, nto leyo inciphisa kakhulu indawo yomgangatho womatshini kunye neendleko zabasebenzi.

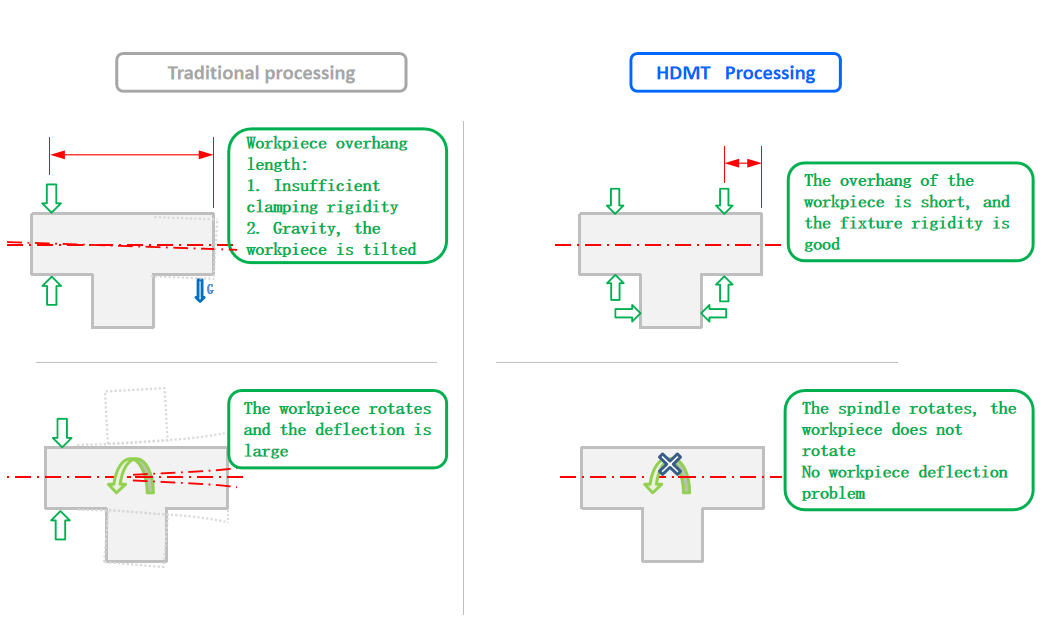

Ukuphambuka koMatshini

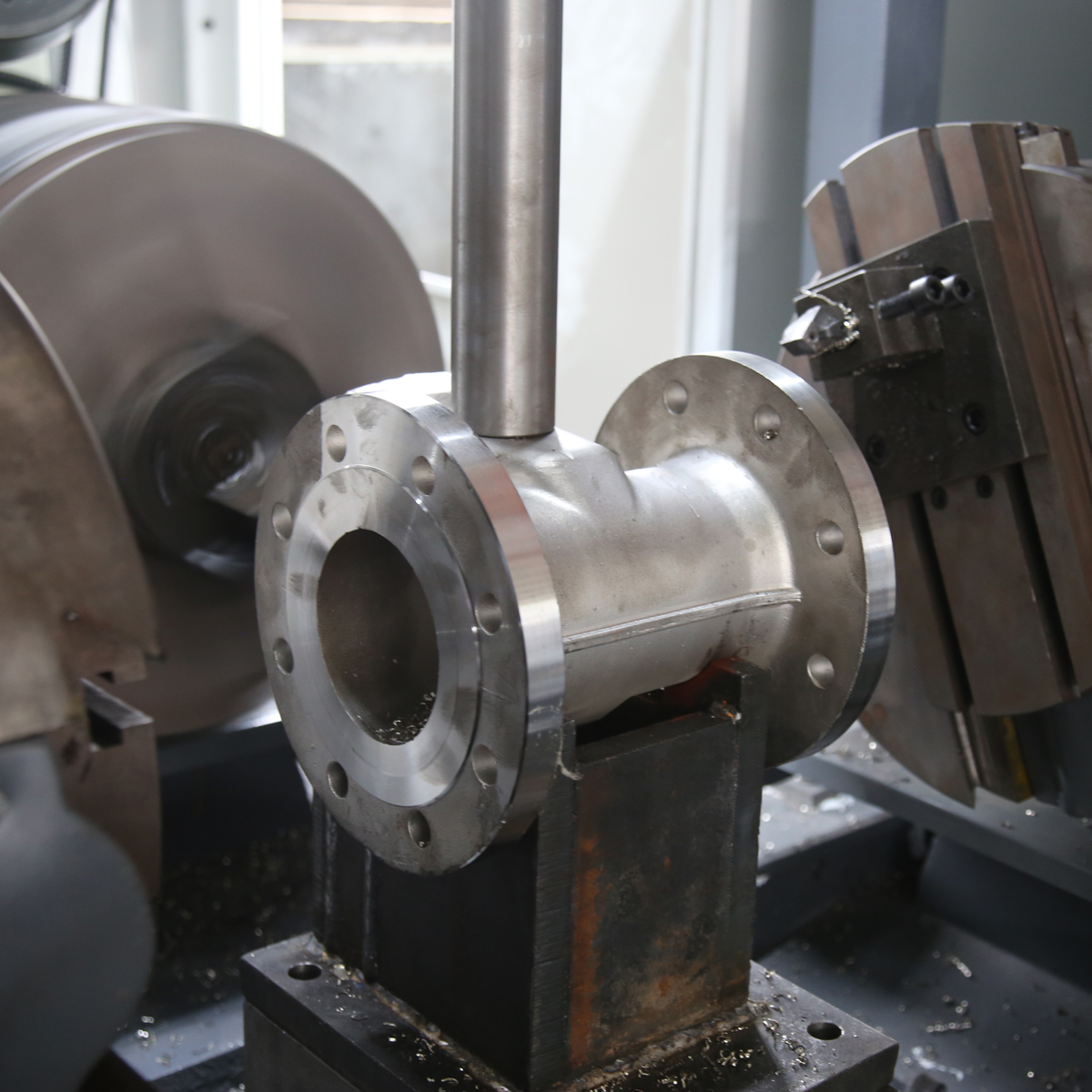

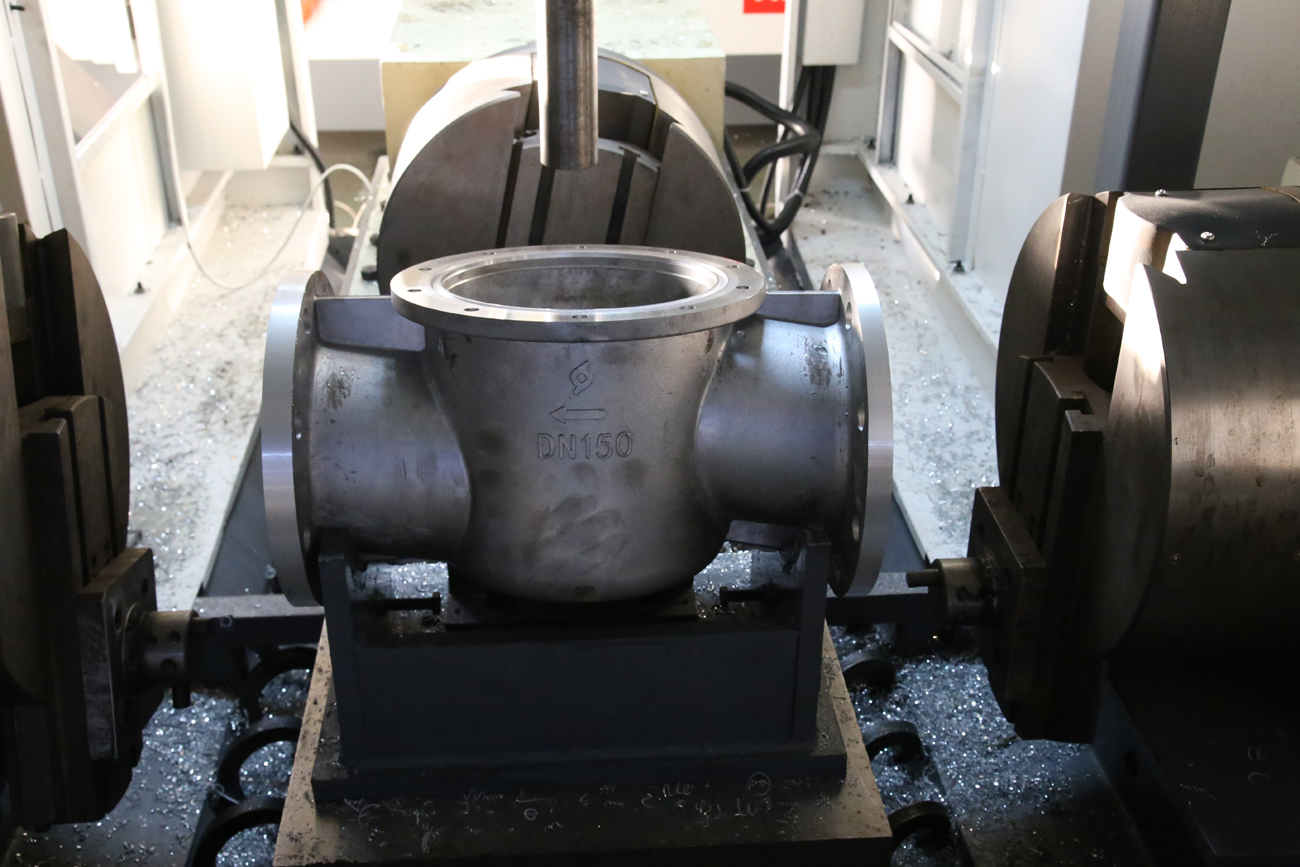

Xa umatshini wokucutshungulwa kwevalve yemveli ugxininisa umsebenzi, kulula ukubangela ukugqithiswa komsebenzi, umsebenzi ojikelezayo, kwaye ukuphambuka kukhulu, okuchaphazela ukuchaneka kokulungiswa kwevalve. I-overhang ye-workpiece imfutshane xa i-workpiece ibanjweI-HDMT CNC yoBuso obuThathu bokuTshintsha umatshini, ubungqongqo bokulungiswa bulungile, imowudi yokusebenza kukujikeleza kwe-spindle, i-workpiece ayijikelezi, ngoko ke akukho ngxaki yokuphambuka kwe-workpiece.

Ubume bokulungisa

Ukulungiswa komatshini wokucutshungulwa kwevalve yemveli inzima ngakumbi, kwaye izinto ezintathu ezahlukeneyo ziyafuneka kubuso obuthathu, okunzima ukusebenza kwaye akukho lula ukuyisebenzisa.I-HDMT CNC yoBuso obuThathu bokuTshintsha umatshiniUkulungiswa kufuna kuphela iseti enye, kunye nesakhiwo esilula kunye nokusebenza okulula.

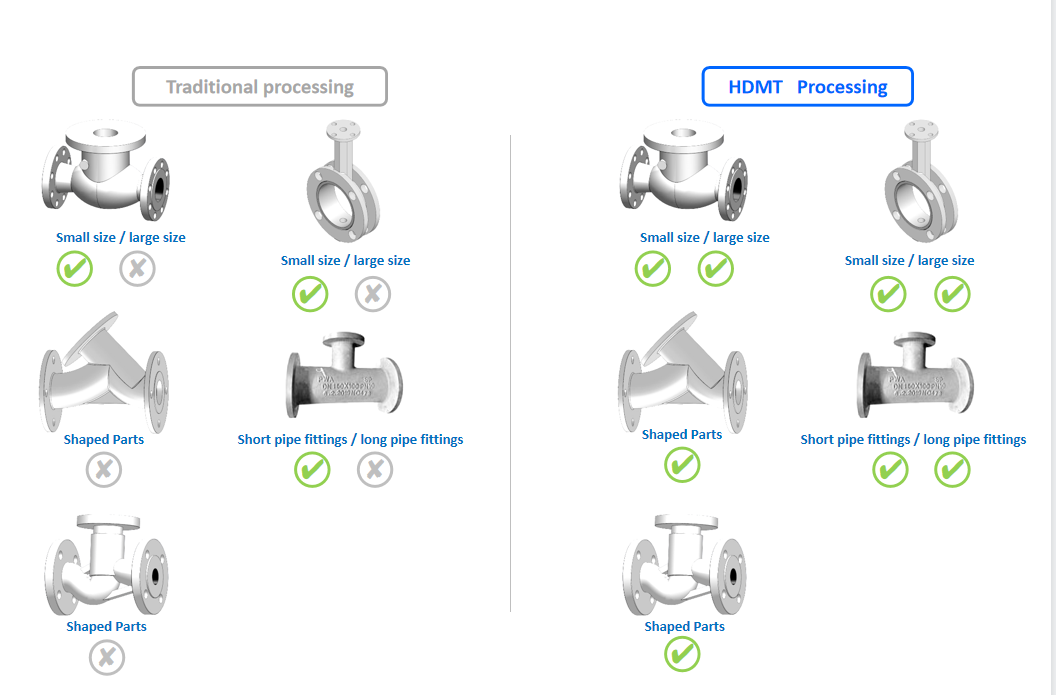

Ukuguquguquka

Umatshini wokucutshungulwa kwevalvu yemveli unemida enkulu xa kusenziwa iivalvu. Ukuba uyila inkcazo encinci, awukwazi ukusebenza ivalve enkulu yokucacisa. Ukuba uyila ukufakwa kombhobho omfutshane, awukwazi ukwenza ivalve ende. Iivalve ezinemilo ekhethekileyo azikwazi ukwenza inkqubo.I-HDMT CNC yoBuso obuThathu bokuTshintsha umatshiniinokucutshungulwa nokuba inkulu okanye incinci, inde okanye imfutshane, imilo ekhethekileyo okanye eqhelekileyo.

Ixesha lokuposa: Oct-14-2021