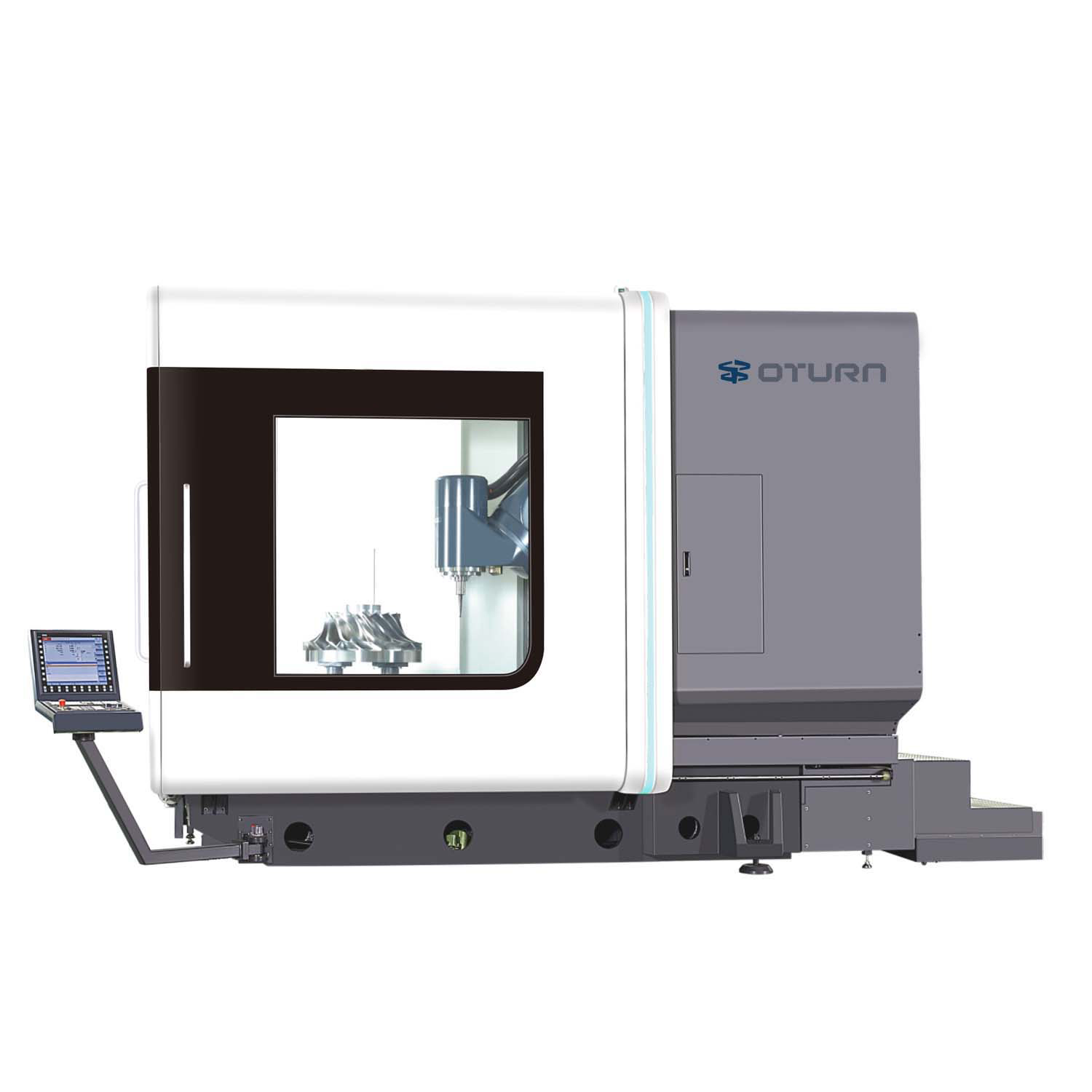

Kwimveliso yanamhlanje, apho ukusebenza kakuhle kunye nokuchaneka kubaluleke kakhulu,iCNC yokusila kunye neziko lomatshini lokujikakuye kwavela njengesisombululo esisebenzayo sokwenziwa kwentsimbi ephezulu. Esi sixhobo esiphucukileyo sidibanisa imisebenzi yokuguqula kunye nokusila kumatshini omnye, okwenza ukuba umatshini wamacandelo anzima kumacala amaninzi ngokuseta enye. Isiphumo kukuncitshiswa okubonakalayo kumaxesha omjikelezo wemveliso kunye nokuphuculwa okuphawulekayo kokuchaneka komatshini.

Inzuzo engundoqo yeumatshini wokusila we-CNCIlele ekukwazini kwayo ukwenza imisebenzi emininzi kwiqonga elinye. Ngokwesiko, ukujika kunye nokugaya kwenziwa koomatshini abahlukeneyo, kufuneke ukuba kudluliselwe ii-workpieces phakathi kwee-setups ezahlukeneyo. Oku akudlanga ixesha kuphela kodwa kwandise ukubakho kweempazamo ngexesha logqithiselo ngalunye kunye nokubamba kwakhona. Ngokudibanisa ezi nkqubo,umatshini wokusila ujike umatshini we-CNCiphucula ukusebenza kakuhle kwaye inciphisa amandla okungahambi kakuhle, njengoko imfuno yemisebenzi yokudibanisa emininzi iyancitshiswa.

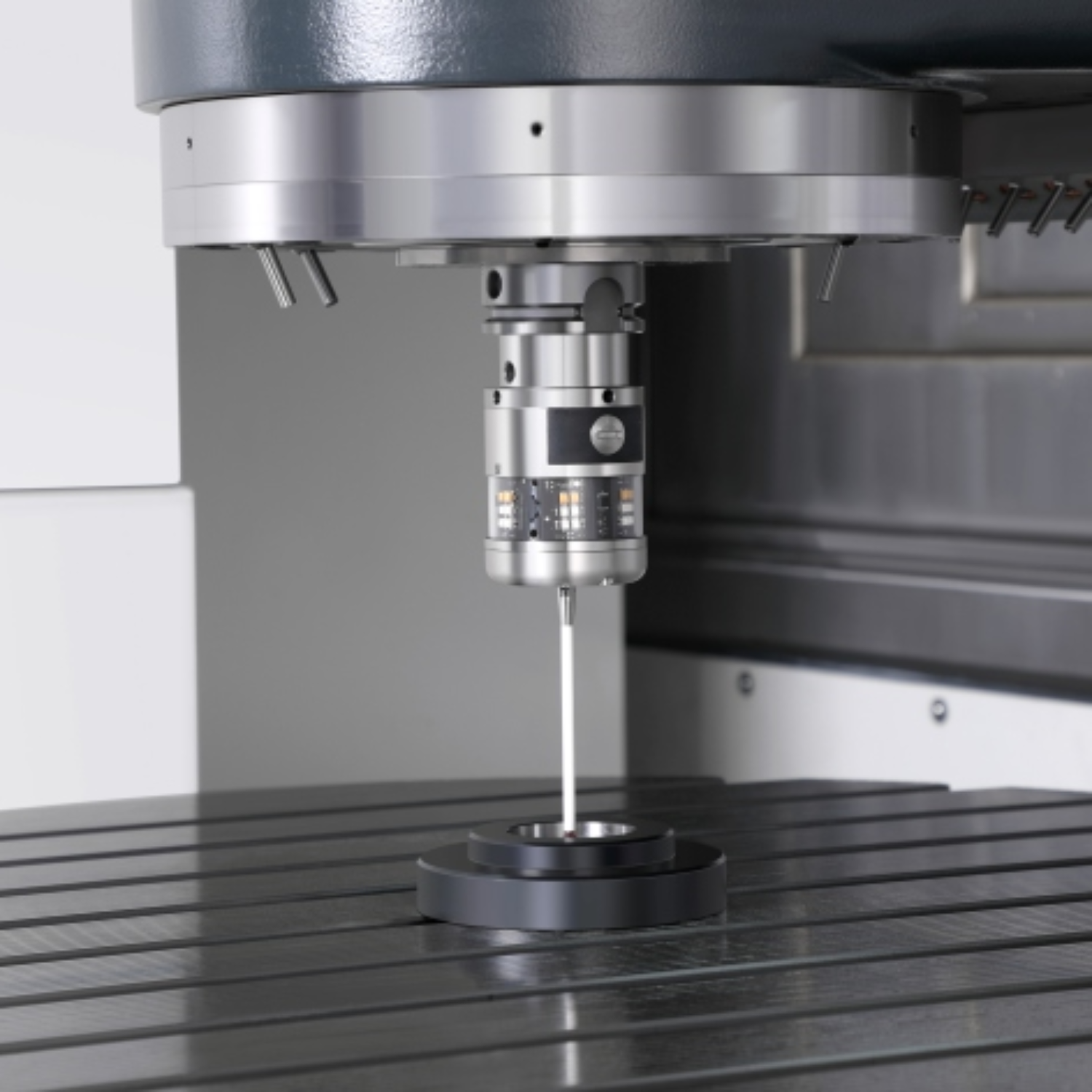

Ukusebenzisa umatshini onjalo ophucukileyo kufuna ukusetyenziswa kwenkqubo ye-CNC ephezulu. Ngokusebenzisa inkqubo echanekileyo, umatshini unokutshintsha ngokuzenzekelayo phakathi kokujika, ukugaya, ukubhola, kunye nokucofa imisebenzi. Eli nqanaba liphezulu lokuzenzekelayo aligcini nje ukunciphisa umthwalo womsebenzi kodwa linciphisa inqanaba lezakhono ezifunekayo ekusebenzeni, okwenza inkqubo yokuvelisa izinzile kwaye ithembekile.

I-CNC yokujika kunye nezixhobo zomatshini wokugaya iikhompawundizisebenza ngokubanzi kuwo wonke amashishini amaninzi, ngakumbi kwi-aerospace, izithuthi, ukwenza umngundo, kunye noomatshini abachanekileyo. Umzekelo, kwimveliso ye-aerospace, aba matshini basetyenziselwa ukuvelisa ii-injini ze-injini, ngelixa kwicandelo leemoto, baqeshwe ekwenzeni izinto eziphambili ezifana nee-crankshafts ze-injini. Ezi zicelo zigxininisa ixabiso lomatshini kwimveliso echanekileyo kunye nemveliso enkulu.

Ukujonga phambili, ukuqhubela phambili kwetekhnoloji kuya kuqhubeka nokukhuthaza ukuvela koomatshini abathatha imisebenzi emininzi ukuya kubukrelekrele obukhulu kunye ne-automation. Ukuhlanganiswa kwee-smart sensors kunye neenkqubo zengxelo yexesha langempela ziya kuvumela ukubeka iliso oluguquguqukayo kunye nohlengahlengiso ngexesha lenkqubo yomatshini, ukuphucula ngakumbi ukuchaneka nokusebenza kakuhle. Ukongezelela, ukufakwa kwe-Intanethi ye-Intanethi yezinto (i-IoT) iteknoloji iya kwenza ukuhanjiswa okude kwedatha yokusebenza kubavelisi okanye amaziko eenkonzo, ukuququzelela ukugcinwa kokuthintela kunye nokulungisa iingxaki. Oku, kuya kunciphisa iindleko zemveliso kunye nokuphucula ukufumaneka kwezixhobo.

Ukuququmbela,i-CNC yokujika kunye nomatshini onzima wokusilaayibandakanyi kuphela ikamva lomatshini wale mihla kodwa ikwasebenza njengesixhobo esinamandla sokuqhuba ukusebenza kakuhle kwimveliso. Ngomsebenzi wayo oncomekayo kunye noluhlu olubanzi lwezicelo, ikhawulezisa utshintsho lweshishini ukuya ekuchanekeni okuphezulu kunye nemveliso. Ukusuka ekuphuculweni kwenkqubo ukuya kwimveliso ekrelekrele, umatshini wokusila uphambili ekuyilweni kwemizi-mveliso kwaye unegalelo elibalulekileyo ekuqhubeleni phambili ubunjineli obuchanekileyo.

Ixesha lokuposa: Sep-13-2024

.png)