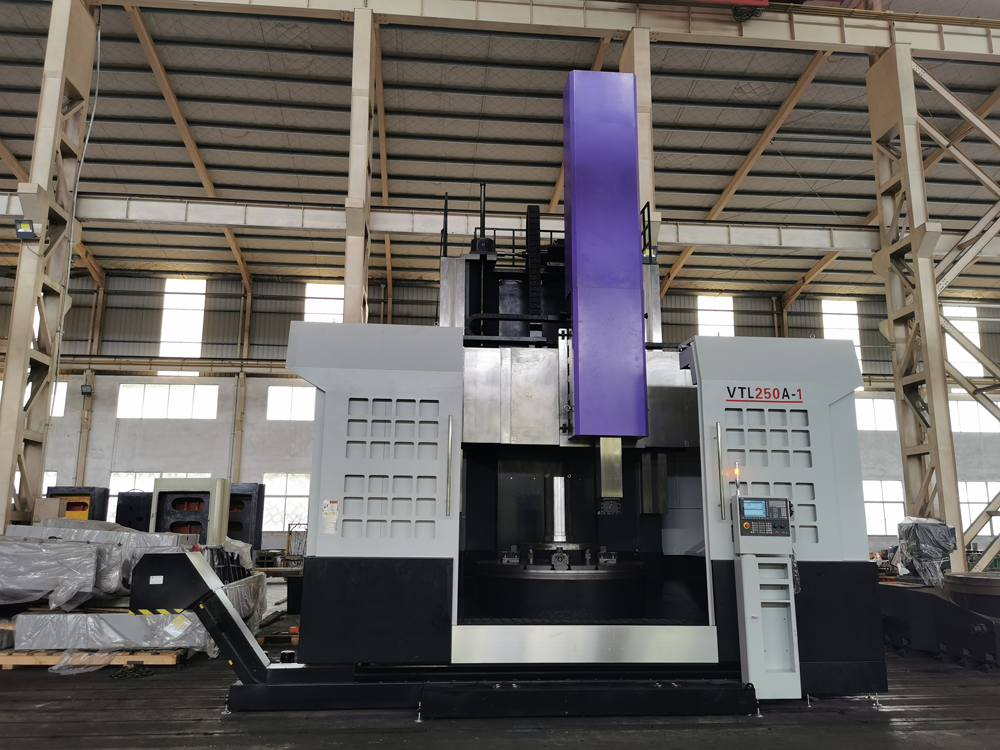

Ubukhulu obukhuluCNC iileyile ezithe nkqongoomatshini abakhulu, abasetyenziselwa ukusetyenzwa kwezixhobo zokusebenza ezinkulu nezinzima ezinemilinganiselo emikhulu yeradial kunye nemilinganiselo ye-axial encinci, kunye neemilo ezintsonkothileyo. Ngokomzekelo, umphezulu we-cylindrical, umphezulu wesiphelo, umphezulu we-conical, umngxuma we-cylindrical, umngxuma odibeneyo weediski ezahlukeneyo, amavili kunye neeseti zezixhobo zokusebenza nazo zinokucutshungulwa ngoncedo lwezixhobo ezongezelelweyo zokuthunga, umphezulu we-spherical, iphrofayili, ukugaya kunye nokugaya.

Ixesha elincedisayo kwizinga elikhuluUmatshini we-CNC VTLimfutshane kakhulu. Inokugqiba yonke imixholo yokucubungula kwi-clamping enye. Zama ukukhetha i-fixture evulekileyo enobunzima obuphezulu, obungenakuphazamisa indlela yesixhobo, kwaye inokugqiba ukucutshungulwa kwendawo yokusebenza ngaphakathi koluhlu lwe-spindle stroke. Njengesixhobo esisebenza kakhulu somatshini, ii-alam ezahlukeneyo ziya kuvela emva kwexesha lokusetyenziswa. Ezinye ziintsilelo zenkqubo, ezinye zizimiselo zeparameter ezingafanelekanga, kwaye ezinye ziintsilelo zoomatshini. Iialamu zabalandeli zezinye zazo.

Xa imeko enjalo isenzeka, jonga ifeni yangaphakathi kuqala. Ukuba ayijiki, yahlukanise, ubone; Ukuba imdaka kakhulu, yisule ngotywala okanye ngepetroli phambi kokuba uyifake. Ukuba kukho i-alamu, kufuneka utshintshe i-amplifier ye-servo. I-HC iyavela. I-alam yangoku, ikakhulu ukufumanisa ngoku engaqhelekanga ngoku kwicala le-DC, jonga kuqala kwiiparamitha ze-servo, kwaye emva koko ususe umgca wamandla wemoto. Ngethuba lexesha, kukho i-alamu yokubuyisela i-servo amplifier. Akukho alarm. Tshintshiselana ngemoto kunye nentambo yamandla kunye nenye iaxis ukuze ubone ukuba ingaba yimoto okanye intambo yombane. Ingxaki: Ukuba i-J ibonakala kwisibonisi, kuxhomekeke ekubeni yingxaki yePC. Jonga ukuba i-motherboard, ibhodi yokuguqula ujongano kunye nesixhobo sebhodi yokulawula ye-PCRAM zichanekile, buyisela kwaye ulungise de kumiselwe unobangela, uze ulungise ingxaki.

Xa imeko enjalo isenzeka, jonga ifeni yangaphakathi kuqala. Ukuba ayijiki, yahlukanise, ubone; Ukuba imdaka kakhulu, yisule ngotywala okanye ngepetroli phambi kokuba uyifake. Ukuba kukho i-alamu, kufuneka utshintshe i-amplifier ye-servo. I-HC iyavela. I-alam yangoku, ikakhulu ukufumanisa ngoku engaqhelekanga ngoku kwicala le-DC, jonga kuqala kwiiparamitha ze-servo, kwaye emva koko ususe umgca wamandla wemoto. Ngethuba lexesha, kukho i-alamu yokubuyisela i-servo amplifier. Akukho alarm. Tshintshiselana ngemoto kunye nentambo yamandla kunye nenye iaxis ukuze ubone ukuba ingaba yimoto okanye intambo yombane. Ingxaki: Ukuba i-J ibonakala kwisibonisi, kuxhomekeke ekubeni yingxaki yePC. Jonga ukuba i-motherboard, ibhodi yokuguqula ujongano kunye nesixhobo sebhodi yokulawula ye-PCRAM zichanekile, buyisela kwaye ulungise de kumiselwe unobangela, uze ulungise ingxaki.

Yeyiphi imiba efuna ukuqwalaselwa kugcino lwe-CNC enkuluVTL Machining?

1. Emva kokuqala i-motor ephambili ngexesha ngalinye, i-spindle ayikwazi ukuqaliswa ngokukhawuleza. Kuphela emva kokuba impompo yokuthambisa isebenze ngokuqhelekileyo kwaye ifestile yeoli iza neoli, i-spindle inokuqaliswa ukuvumela isixhobo somatshini sisebenze.

2. I-screw ingasetyenziselwa kuphela xa ujika imicu ukuqinisekisa ukuchaneka kwayo kunye nobomi.

3. Gcina ngaphakathi nangaphandle kweisixhobo somatshiniukuba uhlambuluke, iinxalenye zomatshini zigqityiwe, i-screw rods kunye neentonga ezikhazimlayo azinayo ioli, kunye neendawo zomzila wesikhokelo zicocekile kwaye zilungile.

4. Yenza umsebenzi wokuthambisa kwindawo nganye yokuthambisa ngokweemfuno ezichaziweyo (jonga imiyalelo yeleyibhile yenkqubo yokuthambisa isixhobo somatshini ukuze ufumane iinkcukacha).

5. Jonga rhoqo kwaye ulungise ukuqina kwe-V-belt yeIleyile ethe nkqo yeCNC.

6. Nika ingqalelo ukujonga imeko yokusebenza yempompo yeoli ukuqinisekisa ukuba ibhokisi yentloko kunye nebhokisi yokutya ineoli eyaneleyo yokuthambisa. I-oyile yokuthambisa kwitanki nganye ayiyi kuba ngaphantsi kombindi womgangatho we-oyile nganye, ngaphandle koko isixhobo somatshini siya konakala ngenxa yokungacoceki kakuhle.

7. Coca i-oyile ye-copper mesh yesihluzo se-oyile kwindawo yokungena yeoli kwibhokisi esecaleni kwebhedi rhoqo ngeveki ukuze uqinisekise ukuba i-oyile yokuthambisa icocekile.

8. Xa i-spindle ijikeleza ngesantya esiphezulu, phantsi kweemeko kufuneka utsale isibambo sokutshintsha.

Ixesha lokuposa: Nov-24-2021