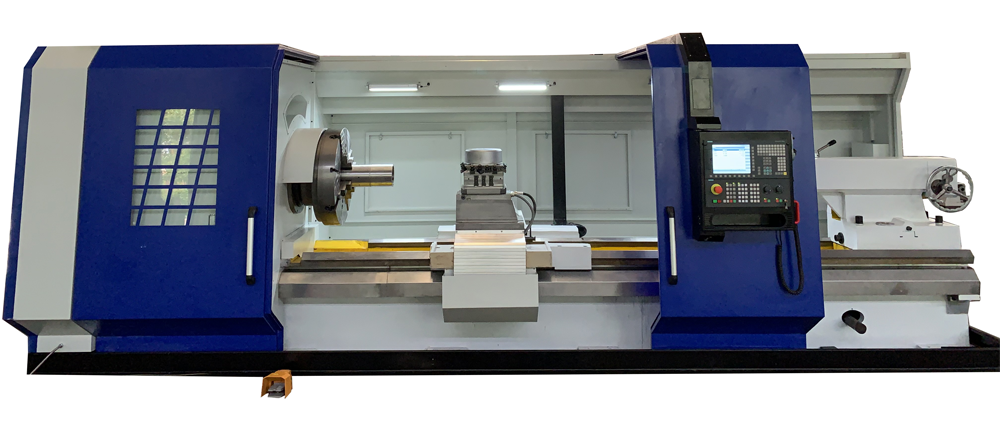

IUmbhobho we-CNC wokuthunga ilatheinokuqhuba imiphezulu eyahlukeneyo yemisonto kunye nemiphezulu ejikelezayo, kwaye ilungele ukujika zonke iintloboimisonto yombhobho. Ukuze umatshini umphezulu ofunekayo we-workpiece, isixhobo kunye ne-workpiece kufuneka igcine intshukumo echanekileyo ehambelanayo, eyenziwa yinkqubo yesofthiwe. Intshukumo yokusonta aumbhobho wokuthunga ilatheyeyona ntshukumo iphambili, kwaye ukuchaneka kokudluliselwa kwayo kuchaphazela ngokuthe ngqo umgangatho womgangatho owenziwe ngomatshini.

Nangona umbhobhoukuthunga i-lathei-lathe ekhethekileyo yoshishino lwe-oilfield, inokusetyenziswa njenge-lathe yendabuko. Amandla okusika ahambelana nesixhobo esikhethiweyo, izinto zokusebenza kunye nesixa sokusika.

Sidla ngokudibana nabanyeisixhobo somatshini we-CNCabathengisi abaya kusicela ukuba sitshintshe uyilo lokusonta lweumbhobho imisonto lathesngokusekelwe kumava lathes zemveli ukwenza ukuba ifane ngokupheleleyo nesakhiwo spindle jikelele CNC lathes, ukuze kuqinisekiswe jikelele izixhobo. Kodwa ukwenza ngokwezifiso okunjalo akunakwenzeka. Oku kulandelayo yintshayelelo eneenkcukacha kwi spindle yeioli ilizwe lathe.

Inxalenye yokusonta yeumbhobho umsonto latheyenye yezinto ezibalulekileyo zesixhobo somatshini, kubandakanywa inkxaso ye-spindle kunye neendawo zokuhambisa ezifakwe kwi-spindle. Ngenxa yesantya esiphezulu, amandla aphezulu, kunye nohlengahlengiso lwezandla lweUmatshini weCNCizixhobo ngexesha lokucubungula, ukuchaneka kokujikeleza okulungileyo, ukuqina kwesakhiwo, ukuxhathisa ukothuka, ukuzinza kwe-thermal, ukuxhatshazwa kokugqoka kunye nokugcinwa ngokuchanekileyo kwamacandelo afunekayo. Ukuze uqonde ukulayishwa ngokuzenzekelayo kunye nokukhulula kunye nokunyanzelisa kwi-spindle, kufuneka kubekho isixhobo esizenzekelayo sokudibanisa isixhobo, isixhobo sokumisa i-spindle kunye nesixhobo esicacileyo sokusika.

Inkxaso yangaphambili yeumsonto wombhobhoi-lathe spindle ithatha iibheringi ezizirowu eziphindwe kabini ezine-cylindrical roller kunye ne-tapered bore yangaphakathi ukuthwala amandla e-radial, okuphucula ukuqina kwe-radial ye-spindle kunye nokuchaneka kokujikeleza kwe-spindle. Iibhodi ezimbini zebhola ze-thrust zisetyenziselwa ukuthwala amandla e-axial kunye nokunciphisa intshukumo ye-axial ye-spindle. I-Momentum iphucula i-axial rigidity ye-spindle. Inkxaso yangasemva ithatha iibheringi zerola eziphindwe kabini ezine-tapered bore, ezidlala indima yenkxaso yeradial.

ICNC umbhobho intambo latheiphuhlisiwe kwaye yenzelwe ujiko lweumbhobho wentsimi yeoliimisonto, kwaye ifanelekile ukuguqula zonke iintlobo zemisonto yombhobho. Iimpawu zemveliso ye-spindle zichaphazela ngokuthe ngqo ukuzinza kunye nokuchaneka okuphezulu kwesixhobo somatshini. Ngenxa yokuba kubaluleke kakhulu ukuhlalutya kunye nokufunda iimpawu eziguqukayo zeyunithi yokusonta. Ngokusebenzisa uhlalutyo lwe-modal ye-spindle, impembelelo yengqiqo yesakhiwo sayo ngokuchaneka kwesixhobo somatshini sifundwa, kwaye amacandelo afanelekileyo aphuculwe ukuhlangabezana neemfuno zesixhobo somatshini wokucubungula umgangatho kunye nokuchaneka.

Ixesha lokuposa: Nov-20-2021