Njengoko sonke sisazi, kwishishini lokwenziwa koomatshini banamhlanje, amashishini anoluhlu olubanzi lwemfunoizixhobo ezikhethekileyo zoomatshini. Ngokubanzi, oomatshini bokomba abaqhelekileyo banobunzulu bokusebenza, ukusebenza okukhethekileyo okuphantsi, imveliso ephantsi kwaye akukho siqinisekiso sokuchaneka; ngelixa i-multi-hole ekhethekileyooomatshini bokwembazifanelekile, zigcina umsebenzi, kulula ukuziqonda, kwaye azityekeleli kwiimpazamo zokusebenza kunye nokusilela. Abanakunciphisa kuphela ukudinwa kwabasebenzi, kwaye baqinisekise ukhuseleko lwabasebenzi kunye noomatshini bokomba. Kukhuselekile kwaye kunokuphucula imveliso yomatshini wokugaya. Ngophuhliso oluqhubekayo lwesayensi kunye nobuchwepheshe,oomatshini bokomba obukhethekileyozisetyenziswa kakhulu kwimveliso. Ngamanye amazwi, okona komelele ngakumbi, kokukhona inkampani inokuqinisekisa umgangatho weemveliso zayo. Ke ngoko, ukusetyenziswa kwezixhobo ezikhethekileyo zoomatshini kudlala indima ebaluleke kakhulu kukhuphiswano lwamashishini.

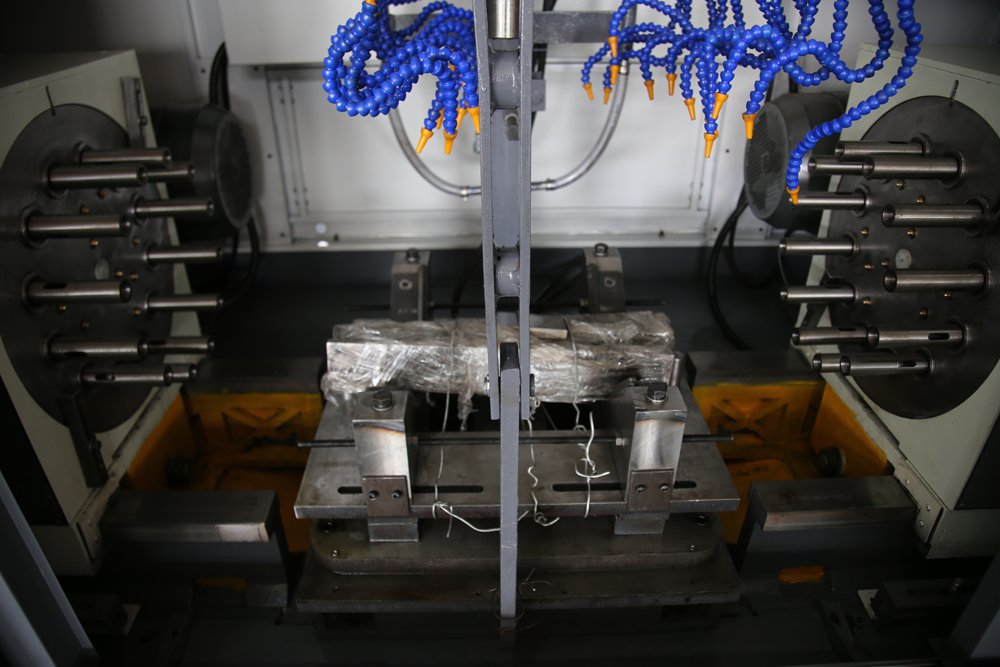

Iumatshini wokugrumba onemingxuma emininzieveliswe ngumzi mveliso wethu ijolise ngokukodwa kwiishishini levalvu. Iyakwazi ukuqonda zonke iintloboiivalve zesango, iivalve butterfly, iivalvu zokulawulakunye nezinye iivalve. Iiflange ezintathu okanye ezimbini ezenziwe ngentsimbi etyhidiweyo okanye intsimbi etyhidiweyo ingabaigrunjwe yacofangaxeshanye. Ukongeza kokunyuka okumangalisayo kokusebenza kwevalvu, ezinye iindawo eziphambili zesicelo, ezinje ngokusetyenzwa kwemizimba yempompo, iindawo zeauto, oomatshini bobunjineli kunye nezinye iindawo, zinokusetyenziselwa ukugrumba ngaxeshanye kwimingxuma yokuphela, imingxuma ephakathi, imingxunya ecikiziweyo kunye. imingxuma engqukuva kwi-workpiece. Ukulungiswa komngxuma. Uninzi-umngxuma drillineendlela ezimbini ze-hydraulic kunye nokusebenza kwenkqubo yokulawula amanani, enokuqonda ukuzenzekelayo, ukuchaneka okuphezulu, iindidi ezininzi, kunye nokuveliswa kobuninzi.

Kukwakho nezinye izilumkiso xa usebenzisaimingxunya emininzi. Senze olu shwankathelo lulandelayo koku:

I-1) I-drill bit kufuneka yenziwe ngokwezifiso kwaye ipakishwe, kwaye kufuneka ilungiswe ngokuqinileyo ngexesha lokuthutha ukuphepha ukungcangcazela kunye nokungqubana.

2) Ukulinganisa i-diameter ye-drill bit, sebenzisa isixhobo sokulinganisa esingadibananga njenge-microscope yesixhobo ukuze ugweme ukwenzakala ngoqhagamshelwano ngoomatshini.

3) Iukugrumba imisonto emininziIntloko yamandla kufuneka isebenzise ireyingi yokugrumba itemplate yokubeka ngexesha lokusetyenziswa, ukwenzela ukuba ulwandiso lwebhithi yokubhola efakwe kwi-spindle kufuneka ilungelelaniswe ukuze ihambelane. Iintambo ezininzioomatshini bokwembaKufuneka unike ingqwalaselo ethe kratya kule ngongoma, ukuze ubunzulu bokomba be-spindle nganye bube bungqinelane.

4) Khangela ukunxiba komgca wokusika we-drill.

5) Iumatshini wokugrumba onemingxuma emininzikufuneka ujonge ubunzulu be-spindle kunye ne-chuck rhoqo. Ukugxila okungalunganga kuya kubangela ukuba i-drill-diameter encinci iphuke kwaye yandise i-diameter yomngxuma. Amandla okubamba angalunganga aya kubangela ukuba isantya sangempela singahambelani nesantya esibekiweyo. Kuya kubakho ukutyibilika phakathi kwamasuntswana e-drill.

6) Ubude bokubambelela kwi-drill drill bit kwi-chuck yi-4 ukuya ku-5 amaxesha ububanzi be-drill shank ukuba ibanjwe ngokuqinileyo.

7) Njalo khangela i-spindle. I-shaft ephambili ayinakushukunyiswa ukukhusela i-drill ephukile kunye nemingxuma inxalenye ngexesha lokugaya.

I-8) Inkqubo yokumisa kwi-workbench ye-drill ye-multi-hole ibekwe ngokuqinileyo kwaye ibekwe phantsi, eyandisa ubomi be-drill bit kunye nokunciphisa iindleko zokuvelisa kunye neendleko. Isiphumo sokugaya ngokugqithisileyo sichasene.

Ixesha lokuposa: Nov-20-2021