Centre Drive lathe For Thin-walled ityhubhu

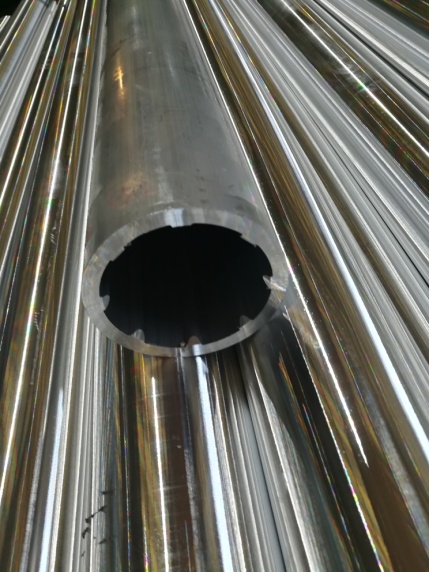

IiNdawo zeMibhobho ezibhityileyo kunye neMibhobho

Isisombululo seTekhnoloji

1.Uhlalutyo lwenkqubo yokucutshungulwa kwamacandelo amancinci angama-cylindrical

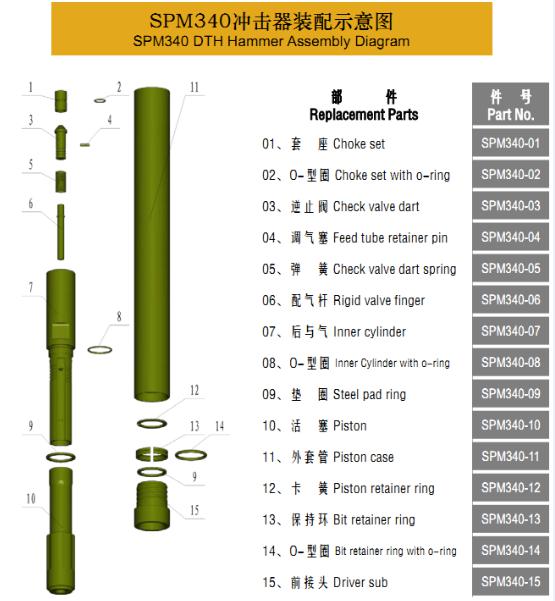

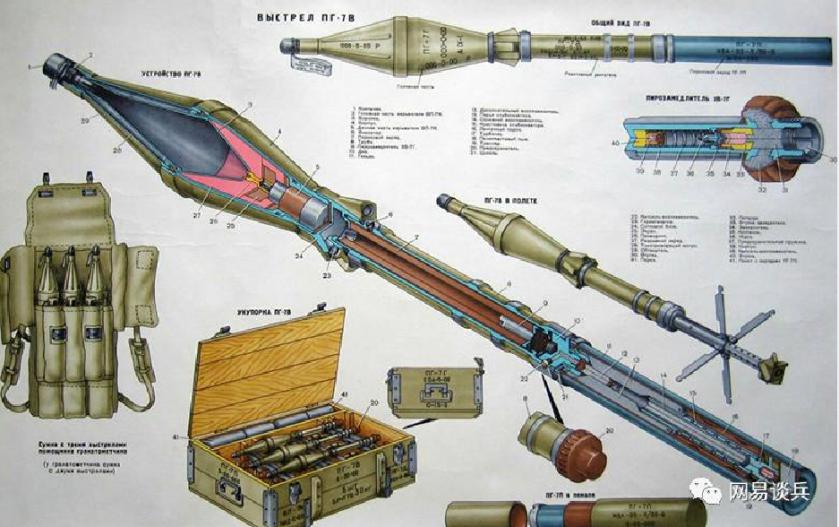

I-tube ene-Thin-walled kunye ne-tube parts isoloko iyinto enzima kwi-machining.Umzekelo: umzimba wompu ogqobhozayo wezixhobo zokugqobhoza ezisetyenziswa kumatshini wepetroleum, igobolondo langaphakathi nangaphandle le-downhole absorber shock, igobolondo langaphakathi nangaphandle lomkhuseli wempompo yeoli, igubu lokuprinta loomatshini bokushicilela, igubu elijikelezayo. oomatshini belaphu, oomatshini bokuhambisa i-Conveyor roller, ukomba ezantsi-umngxuma kunye nezixhobo zokuqhushumba

I-casing yangaphandle, njl., kunjalo, ikwabandakanya amaqokobhe eembumbulu zomkhosi okanye zabantu.

1.1Amalungu aqhelekileyo

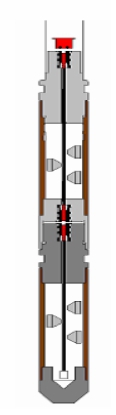

Ubume bompu wokugqobhoza: amacandelo aphambili ompu wokugqobhoza ngumzimba wompu, intloko yompu, umsila wompu, ijoyini ephakathi, i-accessory detonation, iringi yokutywina kunye nesibambi sekhatriji.Iimfuno ezisisiseko zokusebenza kompu wokudubula.Njengeyona nxalenye iphambili ye-perforator yamandla emile, eyona nto isisiseko sompu we-perforating ngamandla ayo omatshini.Kuphela xa iipropati zayo zomatshini zidibene, i-perforator yamandla emileyo iya kuqinisekiswa Ukunokwenzeka kunye nokhuseleko ngexesha lokugqobhoza kwe-downhole.

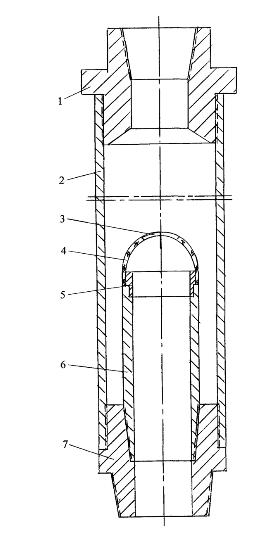

Umkhuseli wempompo yeoli

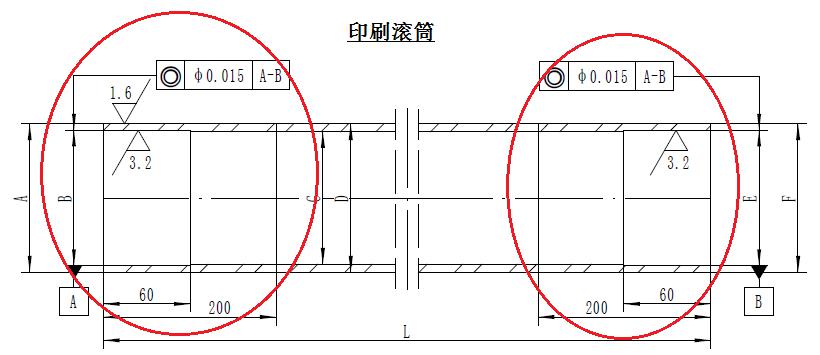

Isilinda sokushicilela

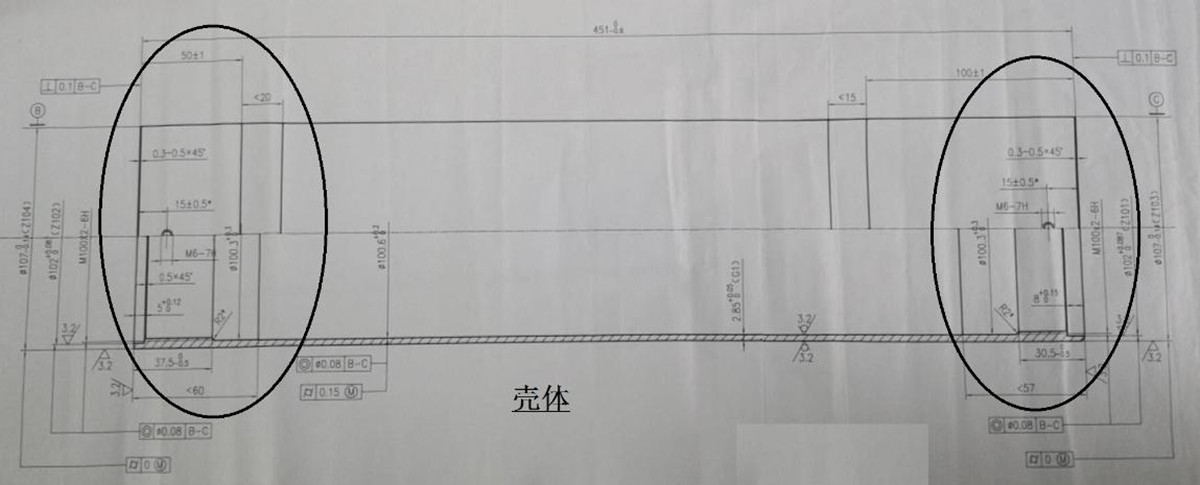

Ukuthelekiswa kweteknoloji entsha kunye nendala ye-fluffor

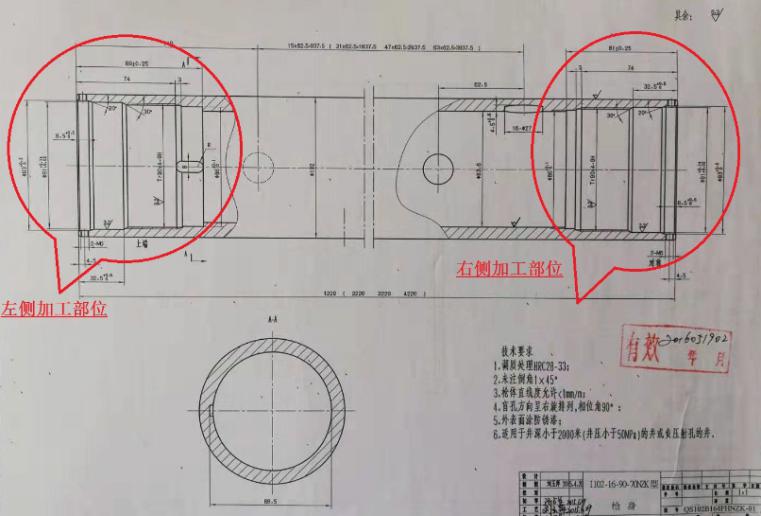

Olu hlobo lwamalungu lunento enye efanayo: imibhobho enodonga olubhityileyo eyenziwe ngokuqengqeleka okanye ukusonta ilungiswa ikakhulu kuzo zombini iziphelo, ukumisa umngxuma ongaphakathi (ukwenzela ukudibanisa), intambo yomngxuma wangaphakathi (yokudibanisa), isangqa esingaphandle esincinci, intambo yangaphandle ( ukuba Kufuneka), ngaphakathi nangaphandle sipes engenanto kunye chamfer

1.2.Uhlalutyo lwenkqubo.

1) Itekhnoloji yokucubungula eqhelekileyo:

Ngokubanzi, isiphelo esinye selathe sisetyenziselwa ukuqinisa, kwaye esinye isiphelo sisebenzisa i-tailstock phezulu komngxuma ongaphakathi kunye nesakhelo esiphakathi semoto, emva koko sebenzisa isakhelo esisembindini ukuxhasa, kwaye emva koko uyadika umngxuma ongaphakathi kwesi siphelo. , isiphelo sobuso bemoto, kunye nomatshini onokuthi ufuneke ekuguquleni isangqa sangaphandle Amacandelo, okanye iindawo zokudibanisa ezifunekayo ekujikeni nasekujikeni.

I-Workpiece U-turn: inkxaso yangaphakathi okanye umzimba we-cylinder clamp yangaphandle, i-tailstock iqinisa i-workpiece, i-socket yesakhelo semoto, inkxaso yesakhelo esiphakathi, umngxuma ongaphakathi wokubhoboza, isiphelo semoto, isangqa sangaphandle.

Ukuba i-coaxiality yemingxuma yangaphakathi kuzo zombini iziphelo ze-cylinder iphezulu kancinane, ukulungiswa kunokuphinda kuphindwe amaxesha amaninzi.

2) Ukusebenzisa itekhnoloji yokucoca i-lathe ye-CNC enesiphelo esiphindwe kabini:

Ukucutshungulwa komxholo ongasentla kunokugqitywa kwi-clamping enye, kwaye zombini iziphelo zinokucutshungulwa ngaxeshanye, ezinganciphisi kuphela inani lezixhobo zoomatshini, kodwa zinciphisa ukuhamba kwenkqubo kunye nokuphathwa kwezinto, kwaye ziphucula kakhulu ukusebenza kakuhle kwemveliso. .Ekubeni zombini iziphelo zicutshungulwa ngaxeshanye, i-coaxiality ye-workpiece nayo iqinisekisiwe ngokuthembekileyo.

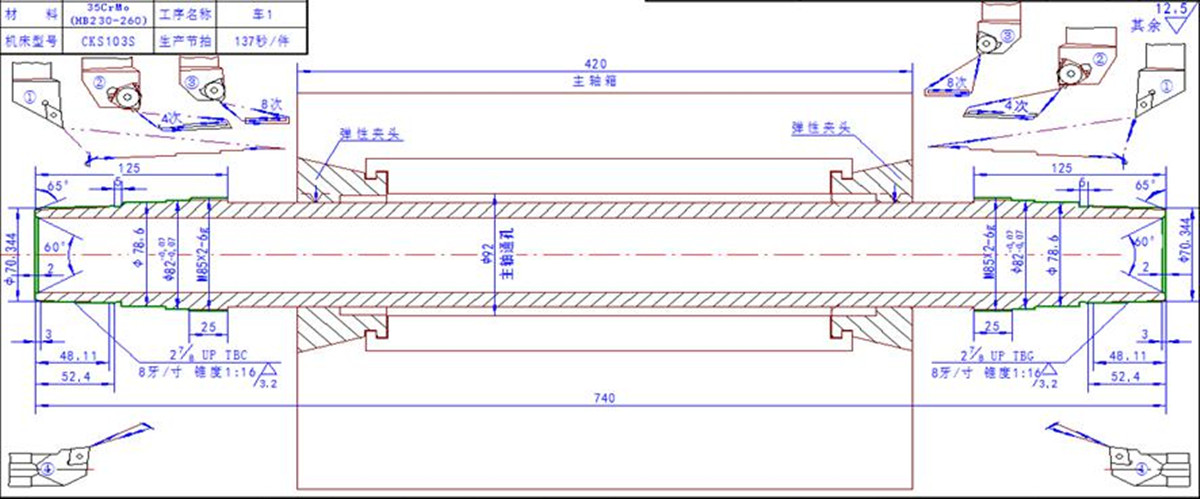

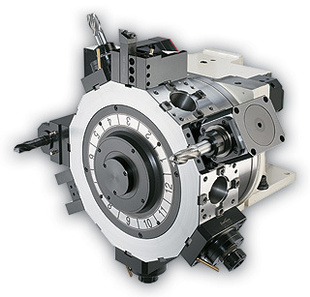

Ngokukodwa: kuxhomekeke kubude bomsebenzi, i-headstock enye okanye ezimbini zingasetyenziselwa ukunyanzelisa isangqa sangaphandle somsebenzi.Ububanzi be-clamping kunye nobubanzi be-clamping ye-headstock bunqunywe ngokobukhulu kunye nobude be-workpiece.Ii-turrets ezimbini ze-8/12-station rotary Ngaxeshanye inkqubo yokuphela kobuso, umngxuma wangaphakathi kunye nesangqa sangaphandle kuzo zombini iziphelo.Njengoko inani lezixhobo ezinokuthi zifakwe zanele, zinokuhlangabezana neemfuno zexesha elilodwa lokucubungula iindawo ezinzima.

Ukuba i-clamping yangaphandle inxalenye yesixhobo somatshini kolu landelelwano kufuneka iqhutywe, ke sebenzisa isixhobo somatshini ukuphindaphinda kabini imingxuma yangaphakathi kwimiphetho yomibini yomsebenzi ukujika okanye ukugaya isangqa sangaphandle.

Kukho kwakhona abathengi abasebenzisa i-grinder engenaziko ukugaya isangqa sangaphandle kwangaphambili, kwaye emva koko basebenzise i-lathe ye-CNC ephindwe kabini ukucubungula imingxuma yangaphakathi kunye nobuso bokuphela kuzo zombini iziphelo kwiimfuno zenkqubo.

3) Amatyala eenxalenye zecylindrical ezicutshungulwa ngamalayile e-CNC aphela kabini:

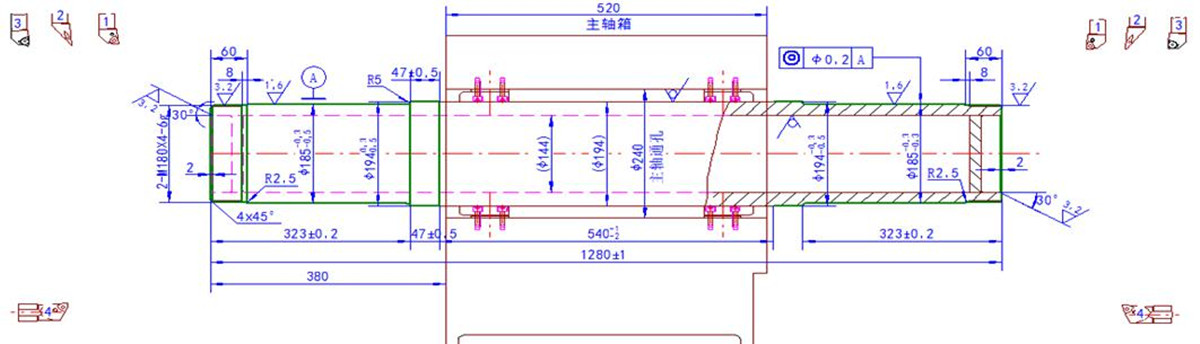

①Ukulungisa isilinda koomatshini bokushicilela, khetha imodeli ye-SCK208S (usebenzisa ibhokisi yokusonta kabini).

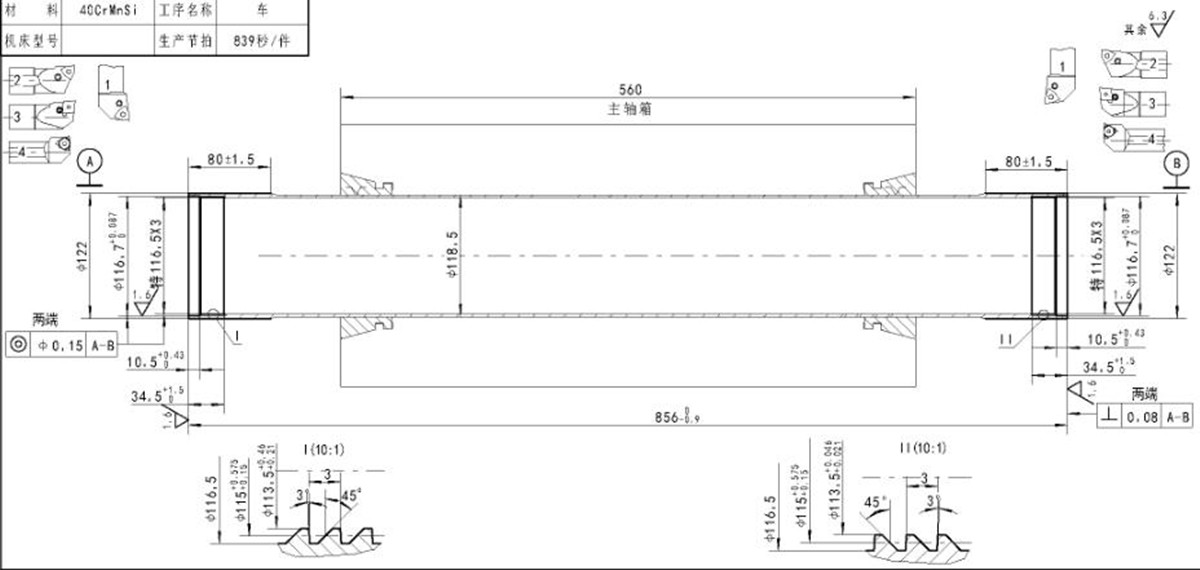

②Imodeli ye-SCK309S (intloko enye) isetyenziselwa ukucubungula i-asi esembindini yemoto.

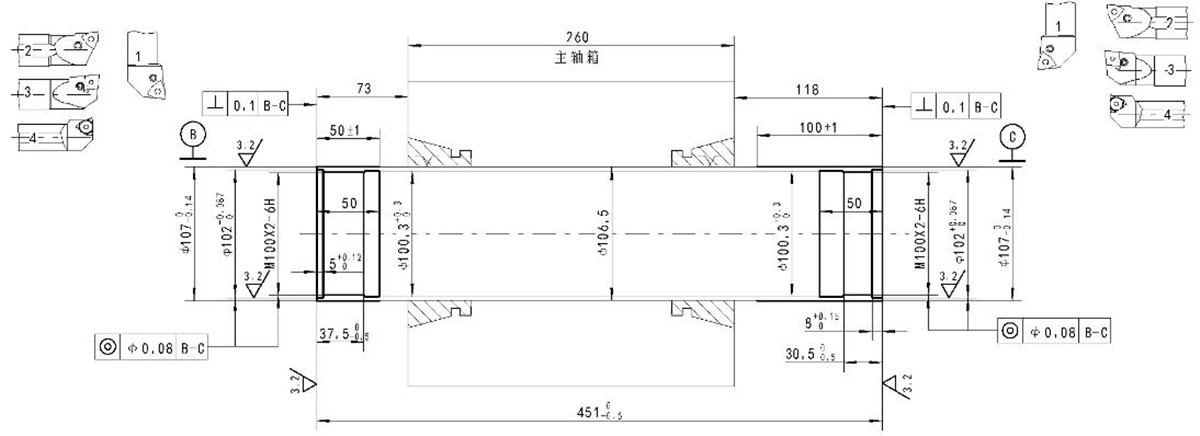

③SCK105S imodeli isetyenziselwa ukusetyenzwa kweetyhubhu zomkhosi ezibhityileyo ezinodonga.

④Ukusetyenzwa kweetyhubhu zomkhosi ezibhityileyo, khetha imodeli ye-SCK103S

⑤ Imodeli ye-SCK105S ikhethelwe ukulungisa imibhobho yeoli koomatshini bepetroli.

SCK Series Double-end CNC Lathe Intshayelelo

■ Umphezulu ophindwe kabini okhethekileyo we-CNC lathe luhlobo lobuchule obuphezulu kunye nesixhobo sokwenziwa esichaneke kakhulu.Inokuthi ngaxeshanye igqibe isangqa sangaphandle, isiphelo sobuso kunye nomngxuma ongaphakathi weziphelo ezimbini zesixhobo sokusebenza kwi-clamping enye.Xa kuthelekiswa nenkqubo yemveli yokubamba iinxalenye kabini kunye nokujika, ineenzuzo zemveliso ephezulu, i-coaxiality elungileyo kunye nokuchaneka okuphezulu kwamacandelo acutshungulwayo.

Okwangoku, kukho iintlobo ezingaphezu kwe-10 zeemodeli, i-clamping diameter: φ5-φ250mm, ubude bokucubungula: 140-3000mm;ukuba iqwalaselwa ngokukodwa kwiindawo zegobolondo zetyhubhu, i-clamping diameter inokufikelela kwi-φ400 mm.

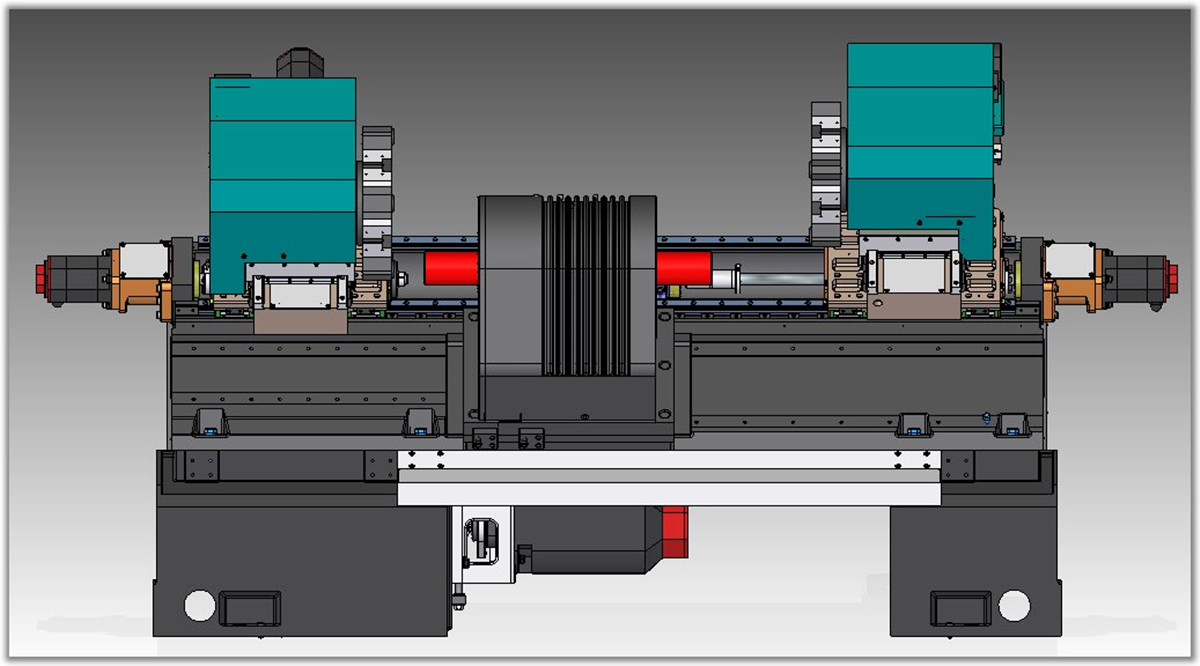

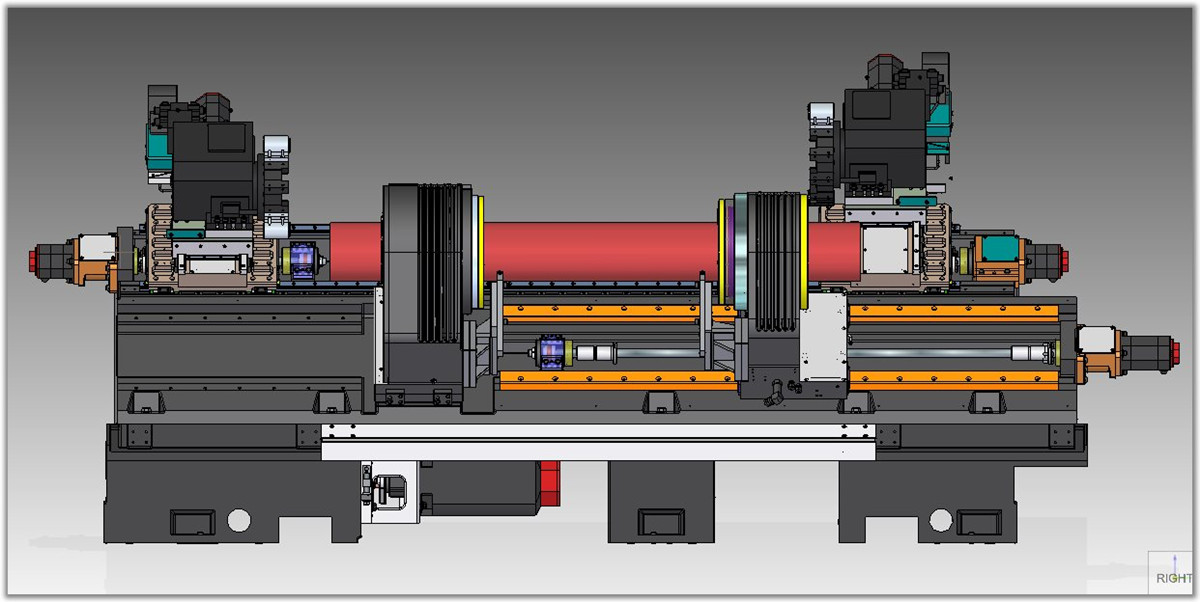

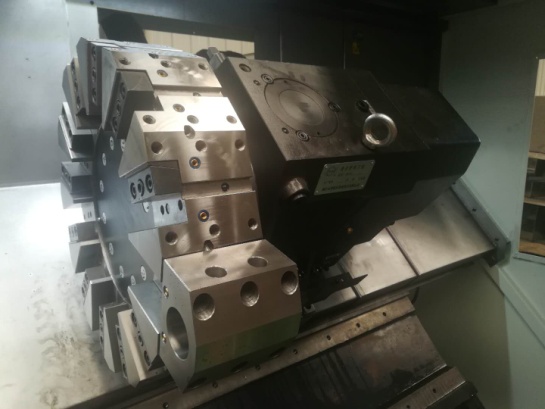

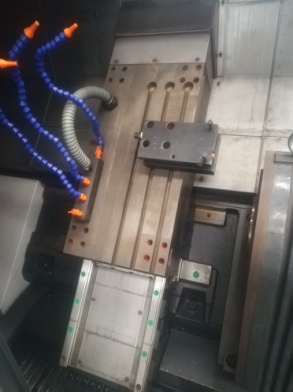

■ Lo matshini uphela unebhedi ethambekele engama-450, enobungqongqo obuhle kunye nokususwa kwetshiphu ekulula ukuyisebenzisa.Ibhokisi yokusonta ene-intermediate drive kunye ne-clamping function icwangciswe embindini webhedi, kwaye izixhobo ezimbini zokuphumla zicwangciswe kumacala omabini ebhokisi yokusonta.

■ Ukusebenzisa inkqubo yokulawula i-channel-channel, izixhobo ezibini zokuphumla zinokudityaniswa ne-spindle ngaxeshanye okanye ngokwahlukeneyo ukugqiba ukusetyenzwa kwangaxeshanye okanye ukusetyenzwa ngokulandelelana kwazo zombini iziphelo zenxalenye.

■I-servo feed axis nganye ithatha isikrufu sebhola esithe cwaka, kwaye i-elastic coupling iqhagamshelwe ngokuthe ngqo, ingxolo ephantsi, ukuchaneka kokuma okuphezulu kunye nokuphindaphinda ukuchaneka kokubeka okuphezulu.

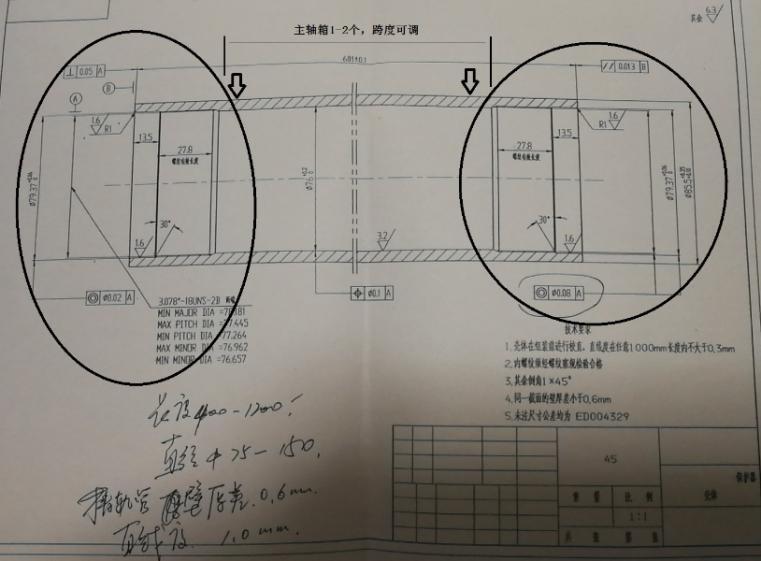

■ Ngokuhambelana nobude beprosesa yee-workpieces ezahlukeneyo, i-1-2 ye-intermediate drive headstocks inokuxhotyiswa.Phakathi kwazo, ibhokisi yokuphotha ephambili ekhohlo ilungisiwe, kwaye ibhokisi ye-sub spindle yasekunene iqhutywa yi-servo motor ukuhambisa isikrufu sebhola kwicala lika-Z.Ingasebenzisa kuphela i-headstock eyintloko ukuze ibambe ukugqiba ukusetyenzwa kwamacandelo amafutshane;inokuphinda isebenzise izitokhwe ezibini zokubopha kunye ukugqibezela ukusetyenzwa kwamalungu amade.

■ Ibhokisi yokusonta idibanisa amacandelo amahlanu enkqubo yokusonta, iintambo, isilinda sokugoba, inkqubo yokuhambisa i-oyile kunye nesixhobo sokuqhuba, kunye nesakhiwo esihlangeneyo kunye nokusebenza okuthembekileyo.Izixhobo zokudibanisa zonke ziqhutywa nge-hydraulically, kwaye i-clamping force inokuhlangabezana neemfuno ze-torque ephezulu yokujika.

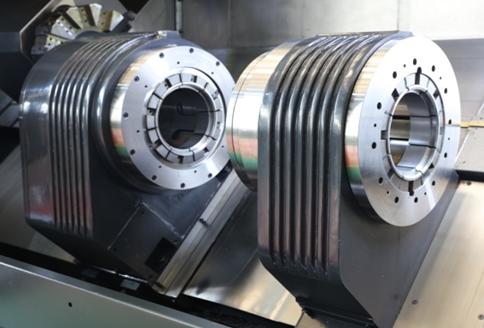

■ Ukulungiswa kufakwe kwibhokisi yokusonta.Ulwakhiwo lwezilungiso lubandakanya uhlobo lwe-collet ene-clamp ephakathi kunye ne-clamp yeziphelo ezimbini, kunye ne-middle clamp kunye neziphelo ezimbini ze-clamp imihlathi.

Ngenxa yeempawu ezilula zokuguquguquka kweendawo ezinqabileyo ezinodonga lwe-cylindrical, i-collet clamps idla ngokusetyenziswa.Iiclamps ziqhutywa yipiston yesilinda ukuze izenze zikhubazeke ngokwanelisayo ukuze ziqonde ukuba i-chuck iyakhulula okanye ibambe.I-deformation ye-elastic chuck yi-2-3mm (ububanzi) .I-chuck ibamba i-clamping inxalenye yecala kuyo yonke i-circumferential direction, i-clamping force ifana, kwaye ukuguqulwa kwenxalenye kuncinci.Xa ukuchaneka komphezulu wenxalenye ye-clamping part ilungile, kuya kubakho ukuchaneka okuphezulu kwe-clamping.Kwangaxeshanye, kubalulekile ukunciphisa ukuguqulwa kwamalungu ukwenza iindawo zibe ne-overhang efanelekileyo.

■Xa amalungu anomlinganiselo omkhulu wedayamitha, uzipho olulungisayo lunokufakwa kwisakhiwo sechuck.Uzipho olulungelelanisayo luzipho oluthambileyo, oluzinze kububanzi bangaphakathi bebamba.Ngaphambi kokusetyenziswa, inokuchaneka okuphezulu kwe-clamping kunye nokutshintshwa ngokukhawuleza kunye nokulula.

■ Umatshini wamkela uyilo lwemodyuli, kwaye unokuba neentlobo ngeentlobo zezakhiwo, ulungelelwaniso kunye nendibaniselwano yokusebenza ngokweemfuno zomsebenzisi.Kukho iinketho ezininzi zesithuba sesixhobo, ezifana nohlobo lwesixhobo somqolo, uhlobo lwe-turret kunye ne-turret yamandla.Izixhobo ezibini zokuphumla zinokudityaniswa kwi-spindle ngexesha elinye okanye ngokwahlukileyo ukugqiba ngaxeshanye okanye ngokulandelelana ukusetyenzwa kweziphelo zombini zenxalenye.

Indibaniselwano yomphathi wesixhobo: isibambi sesixhobo esiphindwe kabini;isixhobo sokukrola kabini;umnini wesixhobo samandla;isixhobo somqolo wasekhohlo+ isibambi sesixhobo sasekunene;isibambi sesixhobo sasekhohlo + isixhobo somqolo wasekunene.

■ Isixhobo somatshini sivalwe ngokupheleleyo kwaye sikhuselwe, sixhotyiswe ngokuthambisa ngokuzenzekelayo kunye nezixhobo zokususa itshiphu ezizenzekelayo, ngokusebenza kakuhle kokhuseleko, inkangeleko entle, ukusebenza ngokulula kunye nokugcinwa kakuhle.

■ Isixhobo somatshini sinokuxhotyiswa ngesakhelo esixhasayo, isixhobo esincedisayo sokulayisha nokukhulula, kunye nesixhobo esizenzekelayo sokulayisha nokukhulula.Bona ividiyo kunye neefoto zoomatshini.